How to safely decrease volume of solder joints?

I hope I'm posting in a right forum!

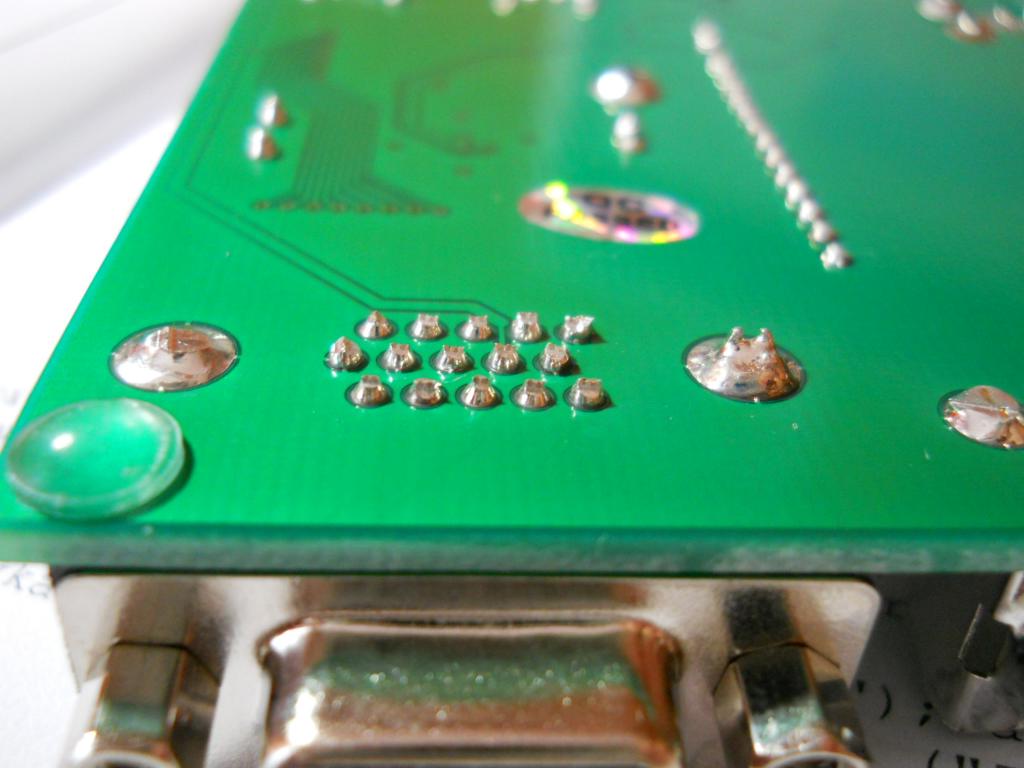

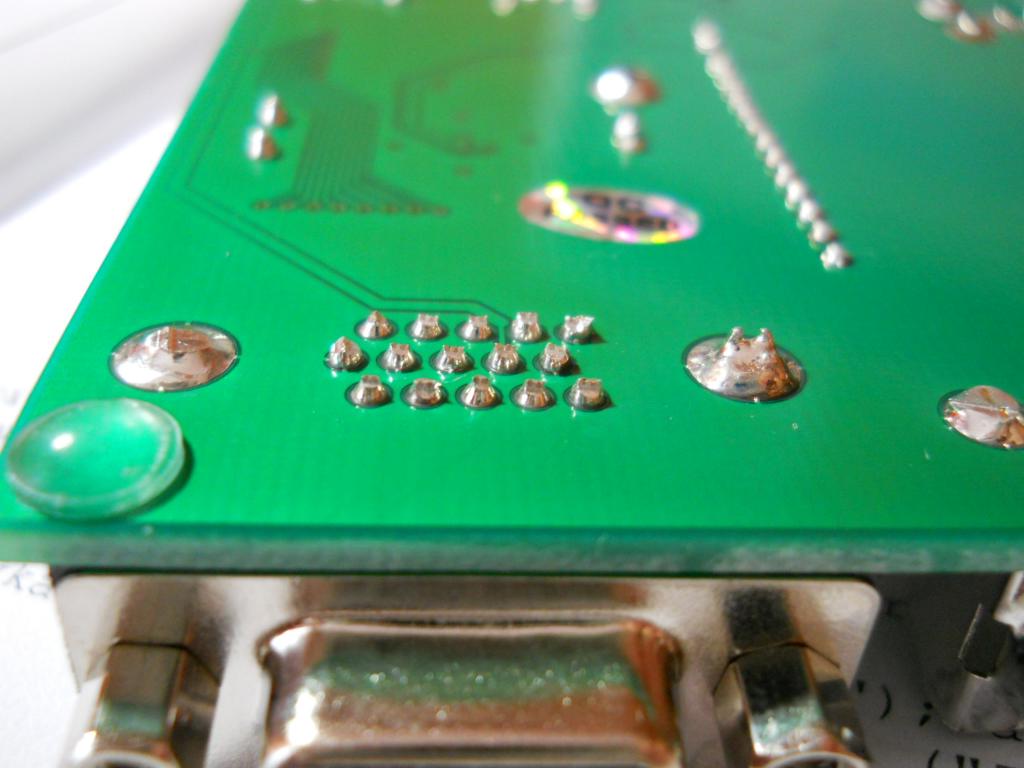

Anyway, I just received my Propeller demo board and I've noticed that most of the larger solder joints had their volume decreased by some tool (sorry, I don't know of a better way to express myself), but they missed one and that is causing me some problems since the joint is taller than the feet of the board.

Here we can see that they got the left joint correctly and the far right joint correctly, but the middle-right joint was not processed.

Now I know that I can just unsolder the joint, bend the offending pins, solder it again and solve the issue in this one particular case, but what I'd like to know is what kind of tools could a hobbyist use to achieve the same effect as seen on the left and far right joint and avoid cracking the joints? I tired using diagonal cutters in the past, but I'd always end up cracking the joint.

Anyway, I just received my Propeller demo board and I've noticed that most of the larger solder joints had their volume decreased by some tool (sorry, I don't know of a better way to express myself), but they missed one and that is causing me some problems since the joint is taller than the feet of the board.

Here we can see that they got the left joint correctly and the far right joint correctly, but the middle-right joint was not processed.

Now I know that I can just unsolder the joint, bend the offending pins, solder it again and solve the issue in this one particular case, but what I'd like to know is what kind of tools could a hobbyist use to achieve the same effect as seen on the left and far right joint and avoid cracking the joints? I tired using diagonal cutters in the past, but I'd always end up cracking the joint.

Comments

Flush cutter

Rich H

Thanks a lot. I'll try to find a tool like that.

@Leon

A very obvious and effective answer, but not the one I was looking for.

Dremmel tool?

Replace feet with taller ones?

File could be a good idea, but it's relatively slow, creates derbies and it could be difficult to get a small enough file for electronics work. Compressed air could take care of the derbies problem, but size would limit files to the edge of the board. A rotary tool with small enough tip looks like a good idea.

High power CO2 laser?

Precisely aimed rifle?

Very sharp Ginzu knife that can cut through anything for the low price of $19.95 if ;you act now within the next 15 minutes?

Just kidding! I would just melt the solder and use a solder sucker or solder wick, or just flick away the excess solder with the tip of the soldering iron. Then, use a pair of diagonal cutters to trim away the extra metal. Pretty much what Leon said.

Oh, I have used fingernail clippers in the past, but they don't work very well for clipping nails after that.