A stroll through manufacturing - found QuickStarts, PropBOEs and C3s in progress!

Ken Gracey

Posts: 7,419

Ken Gracey

Posts: 7,419

Riding a desk all day has some drawbacks, but there's one way to clear your head - walk through manufacturing. I pity any engineer who ever tries to hand our manufacturing staff a half-baked design or one that wasn't optimized for our process. Not only can they build our products very effectively, they also know exactly how things are supposed to work as a result of trainings, testing procedures, and sometimes personal interest.

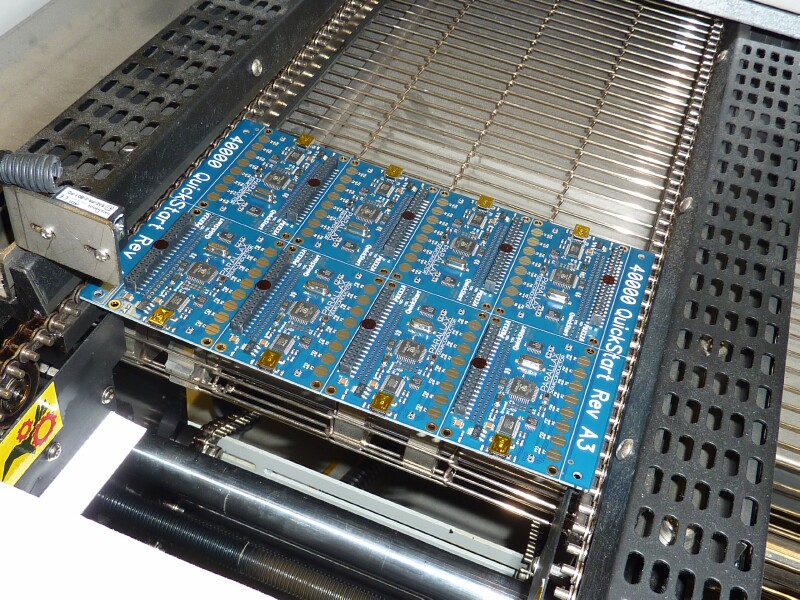

Looks like the first batch of QuickStarts are rolling off the production line today, as perfect as I expected them to be. Great job, David Carrier! We're on target for our June 1st shipping date.

The Pick and Place threw an error to Matt when it set a USB connector on sideways. Guess the machine vision feedback got confused. He acted like it was no big deal (just part of setup) and told me politely to go look at the reflow oven.

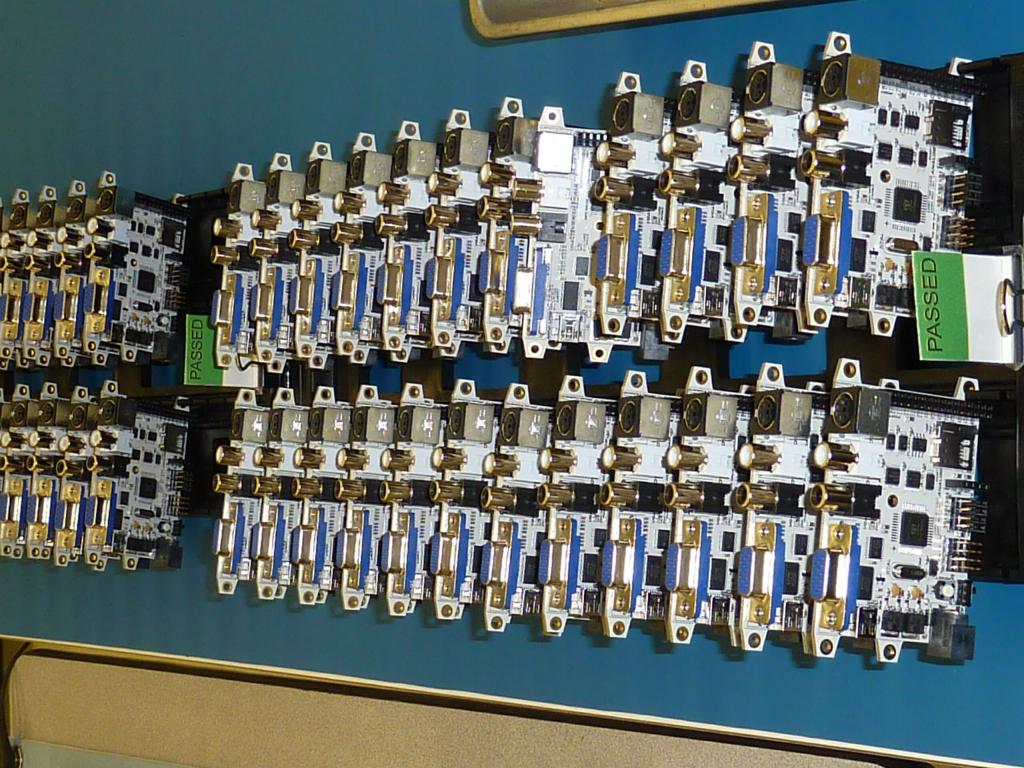

Very exciting to see a few racks of C3 boards with the "PASSED" label on the front of them. I didn't see any failed units so our yield seems to be quite high at this point, finally.

These are the remaining untested Propeller BOEs from last week's production run of 30 units. The testing and qualification behind this board is quite extensive - Andy ran a class before UPEW in front of 20 educators who used the PropBOE with the new educational program. A correct PropBOE design will have very few revisions in its lifetime, just like the BASIC Stamp BOE. Turns out that these boards were sequestered due to a power supply issue. David identified the problem while chatting to me about the next internal revision.

Looks like the first batch of QuickStarts are rolling off the production line today, as perfect as I expected them to be. Great job, David Carrier! We're on target for our June 1st shipping date.

The Pick and Place threw an error to Matt when it set a USB connector on sideways. Guess the machine vision feedback got confused. He acted like it was no big deal (just part of setup) and told me politely to go look at the reflow oven.

Very exciting to see a few racks of C3 boards with the "PASSED" label on the front of them. I didn't see any failed units so our yield seems to be quite high at this point, finally.

These are the remaining untested Propeller BOEs from last week's production run of 30 units. The testing and qualification behind this board is quite extensive - Andy ran a class before UPEW in front of 20 educators who used the PropBOE with the new educational program. A correct PropBOE design will have very few revisions in its lifetime, just like the BASIC Stamp BOE. Turns out that these boards were sequestered due to a power supply issue. David identified the problem while chatting to me about the next internal revision.

Comments

Thanks for reminding me about a certain preorder that I've been meaning to place

schill, I'd only spend your money like it were my own. I don't spend money very often or very easily, either. Last night I went through Lowe's, Sportsmen's Warehouse and Home Depot and left with nothing. My last stop was at an electronics supplier who got $18 from me for a metal aluminum enclosure. I was looking for a small metal project box. After I opened it up I wasn't too impressed with what I found (.050 AL was just a bit too flimsy). Knowing their return process is a hassle I think I'll find another use for this particular enclosure.

Anyway, thank you for the order!

Ken Gracey

My kind of trip...

Too bad Shell got you for @4.09 a gallon on that trip.. I was pleasantly greeted by $3.69 when I returned to Ohio.

OBC

Yeah, rub it in.

Jeff T.

Around here, Matt H. is known as "Mister PicNplace". It's really cool for me to watch the "crew" (Dennis, Terrell, Sue, Monica, Rich, etc.) in action everyday...although I never help much - mostly I just get in the way!

Jeff T., you're right - although it doesn't get it right every time - that's why we're fortunate to have such a talented staff to *catch* the machine's goofs...

-Matt

It uses mini-USB for programming, but is the jack at the rear an RS-232 jack, just a WiFi module connector, or VGA?

These are still internal revisions of the PropBOE and its URL still hasn't gone live. But can you tell us if you plan to release it as a PropBOEBot or is it an add on to the BOEBot?

Paul

Guaranteed by design?

In-house-built tester?

In-house-testing w/ATE vendor system?

Outside vendor testing?

Regards,

DJ

Hey Dave,

It would take a significant message to convey the processes, but I'll try my best to give you a short answer. All of our procedures are documented on an internal Wiki, and they can be edited by any of our staff as long as changes are communicated to others. The procedures are live and never become stale. Other procedures are managed by our business software when incoming parts are received, quarantined, inspected and accepted before they go into inventory. Other processes that fall into the same automated category include having supplier/mfgr part numbers in our business software BOMs so that the Purchasing Manager can't order a substitute without approval. All processes are designed to be functional without being a burden, to be efficient but without bureaucracy, to avoid having any single person not having a double, and they should never take the place of simply having human judgment as an overriding factor.

To be closer to the point, you asked how finished boards are proofed (so I'll skip the steps that lead up to having a finished board):

- Raw PCBs and components are inspected before accepting into inventory

- Cycle counting occurs in an A/B/C scenario to provide 99.98% inventory accuracy prior to any builds. Variances are continually adjusted in our ERP software so that when we go to build we have all the parts.

- Cross-inspections occur between manufacturing and engineering (specifically, the Product Owner) for stencil ordering, PCB ordering, and initial setup

- First inspection is visual, at the solder paste machine

- Next inspection is at the Pick-n-Place, prior to entering reflow oven

- Reflow visual inspection

- Selective solder follows the same steps

- Hardware test is done with in-house built testers, usually on the same board with pogo pins or with a simple plug-in testing device. Every pin or hardware I/O facility is tested for functionality.

- Packaging provides additional visual inspection prior to kitting

- Kitting operation provides a final, lightweight look at the product. Since some parts don't follow the exact same process this is actually an important step. Consider the flow from machining to product, with anodizing in between. Unless we tag all incoming anodized parts for inspection (which we do now), kitting could serve as the last opportunity to identify a QA/QC problem

I am not too familiar with Automatic Test Equipment (ATE) that can accommodate the wide variety of PCB products we produce without some extensive setup, but I could look into it at some point if we need to.

The tests usually use our own tools - Propeller and BASIC Stamp code editors. While all tests can be reduced to a Pass/Fail, we make every effort to give the manufacturing staff far more information about locations and types of failures.

Chips follow a totally different path. What we do above applies to our Made in the USA manufacturing here in Rocklin, California.

Ken Gracey

I really enjoy hanging out on the forums. It gives me every excuse I need to avoid real work!

What you have identified as the RS-232 port is actually a slim VGA connector (left side, above USB). The WiFi connector is the 2x4 header block on top.

The PropBOE will initially be released on August 1, 2011 with some supporting high-level objects that were demonstrated last week at our Educator's Course before UPEW. These same objects are becoming part of the Propeller MicroC, too.

And, as you pointed out, the PropBot is the next goal for use with the PropBot. You notice that it has servo headers, but we will likely provide an externl H-bridge for DC motor control, along with a new chassis.

Doing it right takes a lot of time.

Ken Gracey

Short, but sweet.

Can you start a thread for the ACE Protech Selective Solder machine, too? I asked Bump to rock-and-roll with a Flip video camera.

I really believe in the ACE Protech KISS machines. They use off-the-shelf components like Gecko drives, Allen Bradley PLCs, Mach3 control software (customized), etc. You can replace these parts yourself without waiting for the special Sales representative to show up who normally proceeds to extract $5,000 from you while you wait six weeks for a special motor to arrive from Germany. Those days are over in my book. Buy American! (no offense to anybody - it's a lot easier for us to build products you want to buy, at the prices you want to pay when we can get quick factory service).

If I were in France I'd probably be saying "buy French!".

Ken Gracey

DJ

Yet, I keep seeing more of wonderful thing about Parallax, Inc. and it is especially nice to work with what they makes (Propeller would be one of my favorite microcontroller, besides Freescale PowerPC microcontroller)!

Sorry this is late; I just joined the forums, and this is my first post. Out of curiosity, what exactly are you preordering?

Hey THAT guy, most importantly, welcome to the Parallax forums! New people get very special treatment around here and amazing assistance from a well-qualified and entertaining group. Don't be afraid to ask any questions you want to ask.

schill is probably referring to the www.parallaxsemiconductor.com QuickStart board, a $20 introductory tool for the Propeller chip.

Ken Gracey

Ken's correct. It was the QuickStart.