Hecka Prop :)

The word "hecka" is used by Silicon Valley teens to mean "a lot" of something.

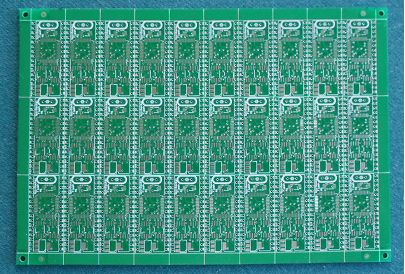

So for the teenagers and kids at heart, here's a HeckaProp board with 30 Propeller islands

For the rest of us, here's a HexProp or Prop 6-Pack board

Those are just intermediate steps of course. The end product is SpinSocket

So for the teenagers and kids at heart, here's a HeckaProp board with 30 Propeller islands

For the rest of us, here's a HexProp or Prop 6-Pack board

Those are just intermediate steps of course. The end product is SpinSocket

Comments

Good one Jazzed::..

Is the bottom v-scored as well? Otherwise you could have them all connected and running diagnostics...

@markaeric, I was thinking frisbee, but that could be dangerous.

Two panels could be stacked for 60 propellers in a space the size of an iPad

Tubuar, yes the 6-pack is just a section from one of the 30 piece panels.

I was able to test them on the SpinSocket Platform board one at a time like that.

Somehow I feel like "Breaking Up is Hard to Do." Sedaka and Kiki Dee ....

I watch Sourth Park, so I know the kids don't say "hecka." "HeliProp" might have been closer!

-Phil

I'm a South Park fan too, but haven't seen it much lately.

(That may actually be a nice size to fit my little graphical LCDs too, I think they're about the same size... Also, the flash and LCD could share the same 8-bit bus...)

The flash shown is 4MB of Winbond W25Q chips. I have some ST chips too.

I plan to leave out the flash on most boards for sale at UPEW, but will have both types with me.

Which LCD do you mean? It would be nice if we can put something together.

Yes, using different chip selects makes it possible to share the 8 pin data.

My GameBaby design currently uses separate pins to simplify the drivers though.

I'd like to use the same pins to allow more features and may do that on another PCB.

@Humanioido,

Getting 10 fully functional panels will be expensive because the yield is not 100%.

It is expected that some modules will not pass PCB electrical test on some panels.

It is expected that some modules will not pass PCB electrical test on some panels.

In that case, put socketed props on both sides of the board and double the density of chips for ten boards with 600 props to make it a worthwhile investment.

Microcontrolled: Normally I'd think you were joking, but after seeing some of your more outlandish projects, I'm thinking you're serious.

I'm serious.

Leon: He wants something like 5,000 I/Os for his Mac.

That's right, but I'll settle for about 5,000 I/Os on the Partitioned Propeller chips, combined with several TeraFlops of processing speed from the Mac.

http://forums.parallax.com/showthread.php?124495-Fill-the-Big-Brain

Wow, I wish I had made these first, that's about $2300 worth of setups.....

This has inspired me to look at your big brain (project :-) ) and I have to say that it is very impressive! I'll be following it with interest now.....

Some find the Bill Brain Project outlandish; I for one Welcome our new Robitc Overlords.

@jazzed - Don't do it! Skynet will not spare its creators!

I have 1 perfect board out of 5.

If you accept up to 4 out of 30 modules per panel being unusable,

then I'll sell you panels. The boards are not RHOS certified.

If you want them assembled, you will have to pay up front.

The boards would be assembled by hand or in an IR oven.

I'm not changing the design to put on 2 propellers per module.

@Jazzed, you should be able to charge a premium price for a board with 100% of the processors working. It would not be unreasonable to charge at least twice the standard price, if not more.

I'm curious who's fabbing your boards. If they're tested, anything less than a 100% delivered yield is unacceptable. I have panels of 20 and 30 produced all the time, and my supplier would not dare ship panels with bad boards.

-Phil

This is a manufactured panel design. It is expected that there be some bad individual modules.

The modules are all tested. The purpose of panelizing is to make the individual modules as cheap as possible. I could ask for individual modules, but not many board houses will produce that.

-Phil

Thank you. You have just made me happy to make all my own boards. I have made over 2000, in my life, with zero bad boards.

If someone wants a panel, it will be on terms we agree to. If you like we can take this discussion off line.

I'm sure you know what you're doing. It's just that I've never been delivered bad boards in a panel. It would really screw up a pick-and-place operation.

-Phil

-Phil

FWIW My TriBlades were made 10 up (14x16" panel) and I had 3 panels made. They actually made a forth panel for me. No panel had all pcbs perfect. Cost was >$800. I was much luckier with my RamBlades with all panels certified, but they were smaller panels 4x7" with 10 pcbs per panel.

I paid for 120 functional SpinSocket-Flash modules which would be 4 panels of 30 modules each.

5 panels were shipped. So I got my 120 modules + 25 more modules for free - I'm happy