Prototyping Robot casing and parts

Hi guys,

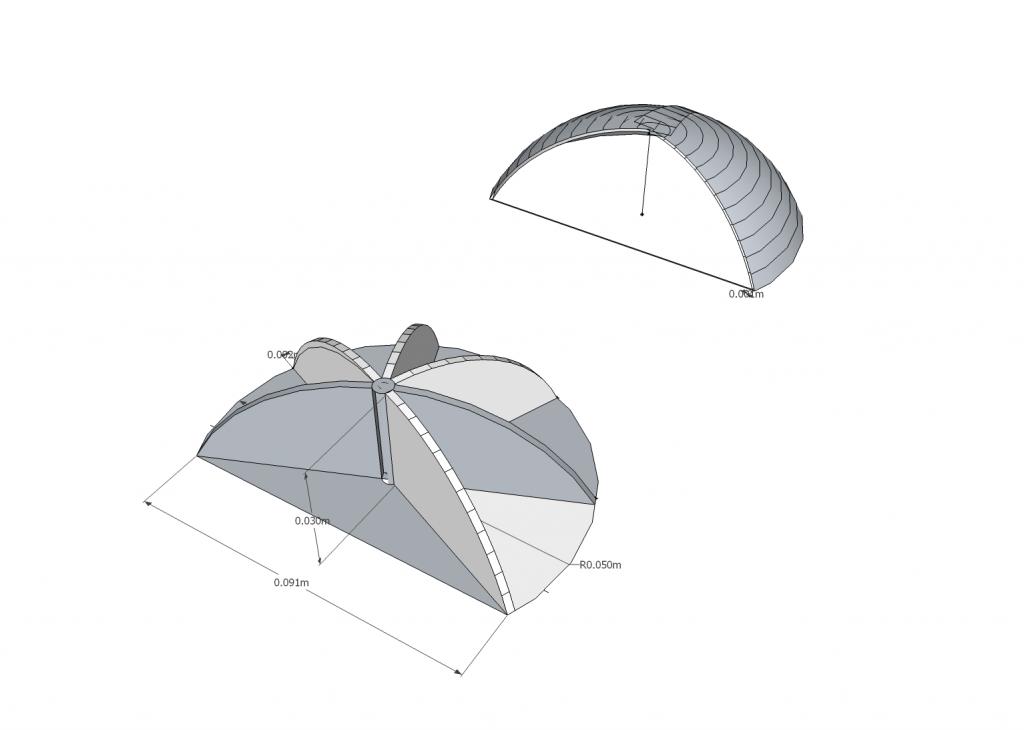

Does any one know how I can make plastic body parts for my Robot please. I have designed an 3D model of an unit using "Google Scketchup". file attached.

I want to make this in black plastic.

Initially I was planing to make it using "Black Gun foam - Polyurethane Casting Foam" found at eBay : http://cgi.ebay.co.uk/ws/eBayISAPI.dll?ViewItem&item=320517689048&category=15271&_trksid=p5197.c0.m619#ht_500wt_922

But I have no clue as to how to even get it going.

Any advice would be super.

Thanks guys

Russell

Does any one know how I can make plastic body parts for my Robot please. I have designed an 3D model of an unit using "Google Scketchup". file attached.

I want to make this in black plastic.

Initially I was planing to make it using "Black Gun foam - Polyurethane Casting Foam" found at eBay : http://cgi.ebay.co.uk/ws/eBayISAPI.dll?ViewItem&item=320517689048&category=15271&_trksid=p5197.c0.m619#ht_500wt_922

But I have no clue as to how to even get it going.

Any advice would be super.

Thanks guys

Russell

Comments

Robert

Maybe send the files to Pololu for a quote. Just make more than one till you learn how to work with the glue - that capillary action can be a bit quick to dry.

- Ken

'

I think it would still be two pieces.

Black plastic is pretty generic, so I'm assuming any black plastic will work. ABS is very inexpensive and easy to cut, easy to bond (glue).... but I don't know what your tolerances are for the DIY method.

black polycarbonate is nicer and inexpensive in this quantity, but very difficult to bond without experience in doing so.

-Phil

http://rld.crai.archi.fr/rld/plugin_details.php?id=429

You can convert your file to stl which you can use with any reprap.

I'm not sure how big your part is, but the Mendel prints up to 8x8 inches, the Huxley 4x4 inches, and soon the Mongo, but I'm not sure what kind of space that will print, except for the fact that it is big enough to have 4 print heads.

http://www.shapeways.com/

Thank you all for the input and advice. as __$WMc%__ mentioned, Im checking out for some 3D printing services here in the UK.

This assembly is for IR detection. I hope to make the dome using some kind of IR filter sheet which I will (if possible ) make using vacuum forming. and the base hopefully 3D printing.

Will upload pictures as soon as I have done it.

Once again, Thank you all for your valuable input. You did push me in the right direction and I appreciate it.

Russell

From my experience, nothing beats hand fabricating a first generation part. Getting your hands dirty is actually fun, and keeps your skills sharp. Using tools safely and properly is becoming a lost art. Shop class isn't taught any more in most public schools!

Second generation parts are more suitable for RP'ing, once you know what you want from hand fabbing. I love Solidworks for the right apps. But I could mock up the OP's front part out of sheet styrene in 10 minutes and find an acrylic dome for the other part that's dang close to the right size. Ultra flat black paint does the rest.

Keep going to your local hobby & hardware stores. Knowing what parts & supplies they have is half the battle. You'd be surprised what a good fabricator can make with sheet styrene (my favorite), or sheet acrylic or pvcx.