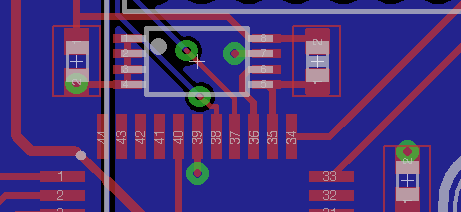

PCB design mistake

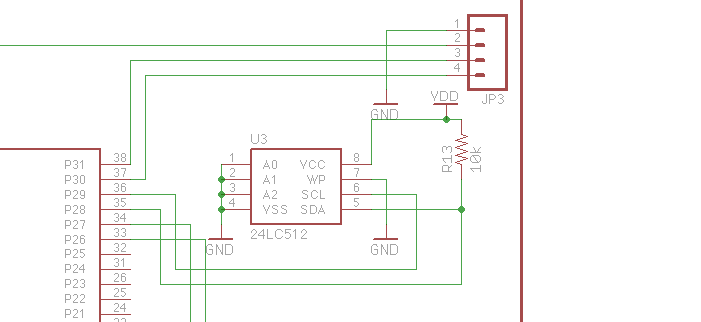

I made a mistake on some boards that I were hoping to actually get right the first time, which has never happened to me. I'd like to avoid another quickturn order, and fix them if possible. What I did was wire the EEPROM's SDA and SCL lines backwards to the Prop (see the picture).

My idea to fix it is this: cut the Prop's pin 28 and pin 29 with a razor blade, leaving just nubs one the Prop, and use the thinnest magnet wire I can find to jumper those pins to their neighbor's original trace. The board doesn't have a solder mask, so at least I have that going for me.

Any suggestions?

My idea to fix it is this: cut the Prop's pin 28 and pin 29 with a razor blade, leaving just nubs one the Prop, and use the thinnest magnet wire I can find to jumper those pins to their neighbor's original trace. The board doesn't have a solder mask, so at least I have that going for me.

Any suggestions?

Comments

Paul

I think it would, if I wasn't impulsive and already cut the pins.

The worst part is when I was laying out the board, I thought to myself that it was easier to route the EEPROM this time around. Of course, because I didn't have to make those two traces jump each other.

the narrow-thickness cutting disk ("cut-off wheel", the red ones); whirrr,

zing-zing, zing-zing, done.

You're fired!

'Glad it works, but ... um ... here's an idea: build a small dam around that part of the PCB and fill it with epoxy. Opaque epoxy.

-Phil

What kind of time frame are you working with? If this is a product you have to deliver to a customer you migh want to consider a second run on the pcb. <grin>

Jus' saying. I do like Phil's idea though.

Paul

Buy a spool of wire-wrap wire for the next time this happens. Trust me, there will be a next time. At 30 ga., it is the perfect size.