Cutting Board Clock

JasonDorie

Posts: 1,930

JasonDorie

Posts: 1,930

This is one that I've been working on for a while, but finally got around to putting some time into it (no pun intended).

The goal is to produce something that, when laid on its back, is a rounded but featureless white slab of cutting board plastic. When stood on edge, the display enables, showing the current time by lighting channels cut into the material from the inside. I'm pretty sensitive to light when trying to sleep, so I wanted something that would dim to almost nothing in darkness, but still be readable. I also wanted the numbers to fade instead of just changing, because that would be cool.

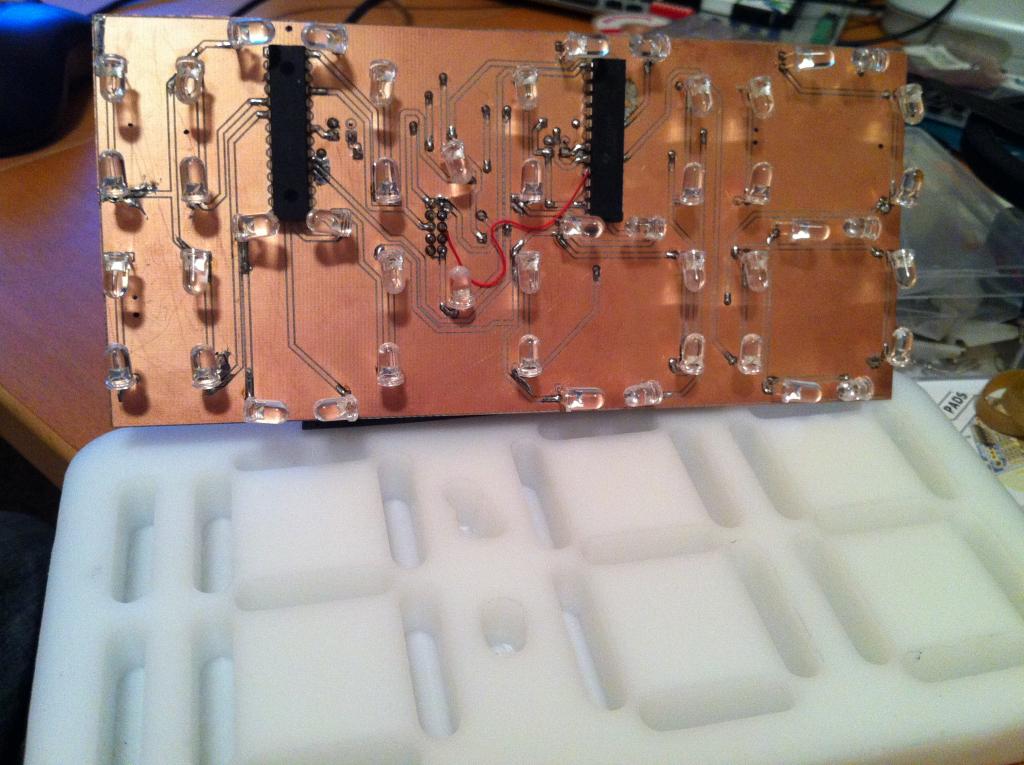

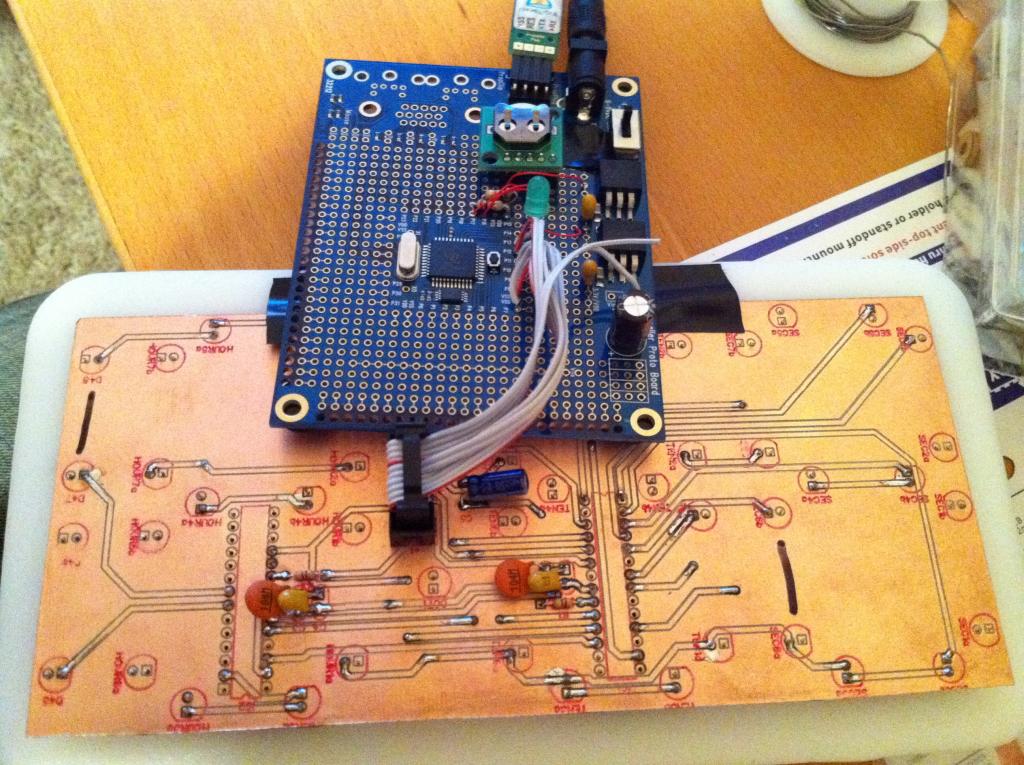

So far I have the front face and the LED board prototyped, and a rough draft of the control software running, including the ambient light detection.

I'm using Kye's DS1307 driver for the real time clock module, and a PASM driver I wrote for the pair of TLC-5940 LED dimmer chips (based largely on Brilldea's RGB painter code). The ambient light sensor is a green LED, wired backwards and using the RCTime code from the PEKit labs. The clock face and the LED driver board were cut using my home-built CNC router.

Photos are attached, and there's a short YouTube clip of it running. The video & pics of the display look really weird - in person the display is much "softer" looking, and doesn't have the strange halo effect present in the pics.

Video: http://www.youtube.com/watch?v=AuJiisMgn-A

The goal is to produce something that, when laid on its back, is a rounded but featureless white slab of cutting board plastic. When stood on edge, the display enables, showing the current time by lighting channels cut into the material from the inside. I'm pretty sensitive to light when trying to sleep, so I wanted something that would dim to almost nothing in darkness, but still be readable. I also wanted the numbers to fade instead of just changing, because that would be cool.

So far I have the front face and the LED board prototyped, and a rough draft of the control software running, including the ambient light detection.

I'm using Kye's DS1307 driver for the real time clock module, and a PASM driver I wrote for the pair of TLC-5940 LED dimmer chips (based largely on Brilldea's RGB painter code). The ambient light sensor is a green LED, wired backwards and using the RCTime code from the PEKit labs. The clock face and the LED driver board were cut using my home-built CNC router.

Photos are attached, and there's a short YouTube clip of it running. The video & pics of the display look really weird - in person the display is much "softer" looking, and doesn't have the strange halo effect present in the pics.

Video: http://www.youtube.com/watch?v=AuJiisMgn-A

Comments

-Phil

I've used a few cutting boards as material for robot parts, most of it machines very nicely with woodworking tools.

C.W.

I think I want to try making the next one all SMT, and include the Prop, eeprom, regulators, and everything else all on one board, then have BatchPCB print them for me. I've soldered TSOP chips, but nothing smaller - I think it's about time I started.

For this version, I have to make a schematic for the Prop side of things and tidy up the code a bit. I'm also having some issues tuning the brightness controls - The response of the RCTime function is non-linear, and I suspect that may also be the case for the LED and CDS cell I'm using, so I'm going to have to come up with something to map the output range of the RCTime function to a range of brightness values for the display. Once I have that a little more solid I'll try to post it all.

Plus, in spite of erco's anti-plastic rants, you couldn't do that with plywood!

- Matt

http://cgi.ebay.com/Koku-All-in-One-Cutting-Board/270694029356?_trksid=p1468660.m2000037

I finally got a function to map RCTime values to brightness in a way I like, so once I add daylight savings handling and the ability to set it I'll post an update.

Matt: Do you see? JD simply used polythylene as a first pass prototype, to hone his skills for the "real deal":

WOOD!

I'll have more words on the subject in a couple days.

-Phil

http://www.instructables.com/id/Solid-Wood-Digital-Clock/

@ Phil - always the prolific peace-maker, always the calming influence in a sea of erco's diatribes.

@ erco - the jury has deliberated, argued, contemplated and came to their verdict...

You sir have entirely too much cellulose in your veins - so much so, that I am vanquished. I lay my plastic sword down, and kneel before your plywood throne!

-Matt

@ erco - Game-on, then sir! However, I must warn you that Phil is Forum-issioner Gordon, and together we shall spar with you well into eternity - well, maybe through the end of next week anyway.

@ Jason too - if you do fall to erco's Dark side (plywood-atosis), there is hope. Yes, erco is lost, but there is antidote if you catch it early enough :-)

touche'! swooosssh. (sound of *plastic* sword being put into scabbard)...

-Matt

Can someone please identify the actual chemical material of this cutting board?

I am looking for lowest dissipation material in 10 to 30 MHz range.

I have narrowed it down to Lexan ( Plexiglass) or LDPE (low density polyethylene).

Ideally I would prefer just to buy the stuff about 1/2 inch thick.

I think cutting board is too flimsy for my usage.

Here is a link to some common plastics.

http://members.tm.net/lapointe/Plastics.htm

Sorry Erco, I cannot use wood - I am dealing with RF of several kV .This is not a typo - that is kilovolts for real.

Vaclav

.

How about starting a new thread for your question?

-Phil

Addendum: Oh, I see Jason answered, so I guess he doesn't mind the intrusion. Have you considered a composite, like linen/phenolic or glass/epoxy?

The fellow I am working with on the project - small transimtting loop antenna - did not recommned any material using epoxy. Too much RF losses.

For what it's worth - neiter Plexiglass or polyethylene are UV resistant. But my atnenna projects usually do not last more than three years anyway.

Just to be forum safe - the antenna will be remotely controlled ( tuning ) and rotation ( compass ) with BS2e.

I am sure it will be a challenge to keep the BS RF safe.

Vaclav

Thanks,

-Phil