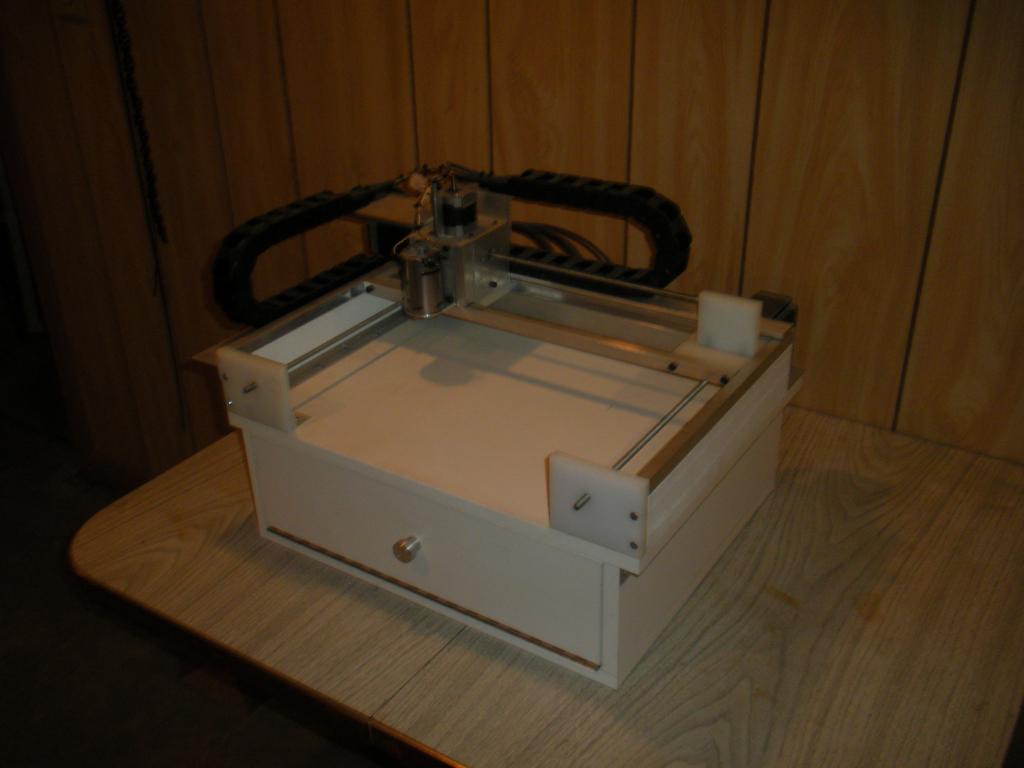

Another Propeller Based CNC Machine In The Works - Photos

idbruce

Posts: 6,197

idbruce

Posts: 6,197

Hello Everyone

Here is another CNC machine that I am in the process of making. It is a PCB drilling machine and this one will operate off of one Propeller Proto Board. This machine will connect to the same power supply as the other CNC's.

Bruce

Here is another CNC machine that I am in the process of making. It is a PCB drilling machine and this one will operate off of one Propeller Proto Board. This machine will connect to the same power supply as the other CNC's.

Bruce

Comments

All custom made my friend

Bruce

What are you using to drive the stepper motors?

As you can clearly see, the electronics are not shown in the photos. I will be using four G251 stepper drives from Gecko Drive to run the motors, and a Propeller Proto Board to send the necessary pulses.

Bruce

g.

The Propeller will be parsing an Eagle DRD file for coordinates.

Bruce

'

I'll be sure to follow this thread for updates you post on this project.

'

Great work.

Thanks Walt

I will keep you guys posted, and post a video when I work on it again. It's kind of funny though, I thought the other CNC's would have caught more interest.

Bruce

'

What are you planning to make with this machine?

It looks nice and when you are done, you will have bouncing baby PC Boards.

I have several projects in mind for this machine, some of which include:

- PCB's for a L6208 based stepper driver

- PCB's for a Propeller based UV LED exposure box

- PCB's for a Propeller based controller for a miniature version of this machine

In the following thread, forum member kbash presented a pretty nice looking circuit board which really caught my interest, I might also do something similar to that.http://forums.parallax.com/showthread.php?129448-Prop-based-CNC-3D-printer

Whatever I decide to make, it will be a profit driven decision. Of course, for a nice guy like you Walt and a few others here, I might make an occassional free circuit board.

Did you take a peek at my other machines on this post?

http://forums.parallax.com/showthread.php?129612-My-Current-Prop-Based-CNC-Photos

Below are some additional photos for my current exposure box, which will go hand in hand with the machine above.

Bruce

I am now thinking of adding a laser diode to the Z-axis of this machine for cutting out cardboard packaging.

Has anyone hacked the laser diode from a CDROM drive?

Bruce

Look at these they should get you started, but I would have to say the cardboard would have to be really thin for this thing to cut it because most DVD laser burners are 1 watt or less. I would say you would set the cardboard on fire before it cut a nice cut. But the hacked lasers are great for popping ballons and lighting cigarettes.

http://showsyouhow.blogspot.com/2007/12/diy-dvd-burner-laser-pointer-proper-way_18.html

http://shop.ebay.com/i.html?_nkw=burning+laser+&_sacat=0&_odkw=10+watt+laser&_osacat=0&_trksid=p3286.c0.m270.l1313

http://shop.ebay.com/?_from=R40&_trksid=m570&_nkw=laser+lens&_sacat=See-All-Categories

Thanks for the links. I am now leaning more towards using some type of cutting bit. Still in the thinking process.

Bruce

If you want to have a real laser setup and I see you dont mind a little DIY take a look at this book. It has alot of info on a Laser Powersupply and cooling requirements.

http://www.amazon.com/Electronic-Gadgets-Genius-Build-Yourself/dp/0071426094/ref=pd_bxgy_b_img_b

Here is a 40 Watt Tube and powersupply so u would have to have cooling pump and lens.

http://cgi.ebay.com/40W-CO2-Laser-Tube-Power-Supply-Cutting-Engraving-/150552923733?pt=LH_DefaultDomain_0&hash=item230da74e55