Super Simple BOE-BOT Work/Test Stand

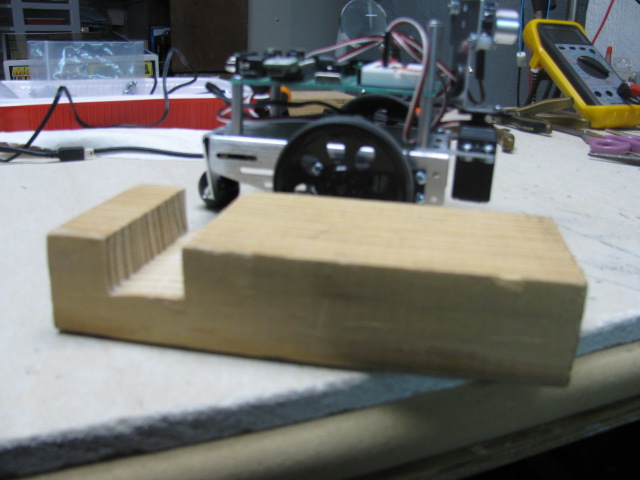

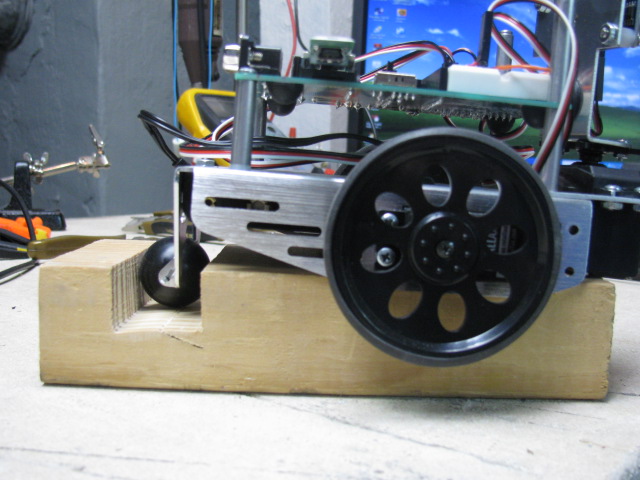

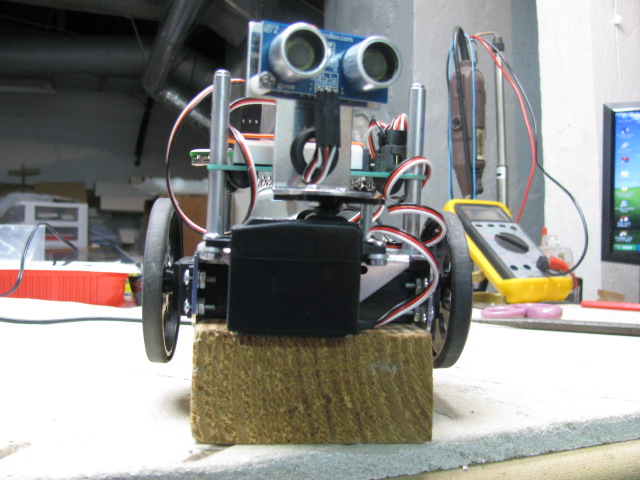

Because Whit said I should and I believe in the use of a work/test stand in robotics building I’m posting some pictures and dimensions for my super simple BOE-BOT work/test stand (I didn’t even take the time to paint it). I made the stand from a single piece of 2x4. You could build the stand from ¾” stock by simply gluing the stock to get the thickness you need. It would make making the tail wheel grove real easy. To see my stand for the Stingray visit this post http://forums.parallax.com/showthread.php?122164-Stingray-Work-Test-Stand

Instructions

1. Rip a piece of 2x4 to 3” wide (for safety start with a longer piece than needed)

2. Cut the 2x4 to 7” long

3. Measure 1” from one end and draw a line across the 2x4.

4. Now measure 2” from the same end and draw a line across the 2x4. These two lines mark the width for the tail wheel grove.

5. Remove the wood between these two lines to a depth of 3/4” (see pictures) I used a band saw, but you could make several cuts across the 2x4 between the lines at a blade depth of ¾” and then use a chisel to remove the waste. Again, if you use ¾” material this step would be saved! Simply leave a 1” space.

6. Now place your BOE-BOT on the work/test stand and enjoy safe coding and testing!

If you should have questions don’t hesitate to post them or PM me.

Ken, if you send me an S2 I will design a stand for it. Please Dad!

Thanks,

Tony

Instructions

1. Rip a piece of 2x4 to 3” wide (for safety start with a longer piece than needed)

2. Cut the 2x4 to 7” long

3. Measure 1” from one end and draw a line across the 2x4.

4. Now measure 2” from the same end and draw a line across the 2x4. These two lines mark the width for the tail wheel grove.

5. Remove the wood between these two lines to a depth of 3/4” (see pictures) I used a band saw, but you could make several cuts across the 2x4 between the lines at a blade depth of ¾” and then use a chisel to remove the waste. Again, if you use ¾” material this step would be saved! Simply leave a 1” space.

6. Now place your BOE-BOT on the work/test stand and enjoy safe coding and testing!

If you should have questions don’t hesitate to post them or PM me.

Ken, if you send me an S2 I will design a stand for it. Please Dad!

Thanks,

Tony

Comments

And from the many "dented baseboard" posts, I'm sure something similar for Stingray would also be appropriate!

The thing is built like a tank! The base is a solid block of aluminum. The rollers are precision, rubber-rimmed idlers with bronze oilite bearings running on ground and hardened shoulder screws. There's a vertical steel rod running up through the pen hole to secure the S2 in place. It's not going anywhere! I added the foam paint roller as a power take-off for the idler wheel, so I could test its analog output characteristics while in motion. Here's a graph:

For development purposes, a static test stand -- whether a block of wood, a jar lid, or something precision-machined -- is an invaluable aid. BTW, for the Scribbler I, I used a plastic 35mm slide box. 'Worked great!

-Phil

Perhaps a servo operated stand. Finish your test run and the little guy just lifts himself up. :-)

Amanda

Nice! Simple and functional. Much more elegant than the "Stand Bob on his nose and watch him fall over" method I'm using. :-)

Amanda