Prop Plug

Anyone have this problem with a Propeller Plug? The connector broke off through plugging in and unplugging to load up numerous prop boards that don't have the USB circuit. I got two of these. One went AWOL so this one got all the use and apparently it was too much. It looks like this will take some store trekking to find a similar one-row SIP connector with four socket pins on the end, and then solder the pins to the Plug. In the meantime, has anyone come up with a way to strengthen the connection points so this won't continue to happen?

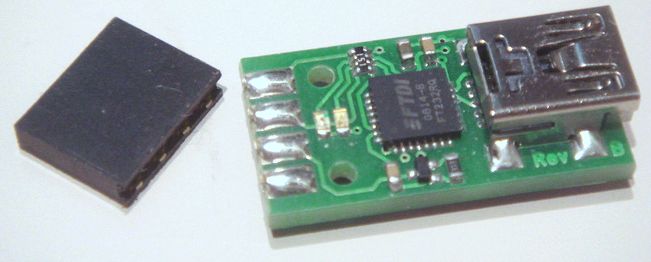

The resulting connector detachment of a Propeller Plug

The resulting connector detachment of a Propeller Plug

Comments

Humanoido, your photo suggests that the broken connector was a surface-mount unit. Is that the case? If so, be sure to replace it with a through-hole part if there are holes in the board. Surface-mount connectors without mounting tabs are much too fragile for repeated connects and disconnects.

If it is a surface-mount connector, Parallax needs to be alerted to this failure mode.

-Phil

You can solder the wire ends to the board, but you will have to strain-relieve the solder joints with something like hot-melt glue to keep the hard-solder/flexible-wire interface from breaking. Better would be to find a 4-conductor extension cable with connectors at both ends. Then you could solder a male header to the Prop Plug board and just plug the cable in.

-Phil

-Phil

Indeed, we had this problem and a few Prop Plugs slipped out the door before we detected the connector problem. We reworked existing stock and qualified a new part for future production runs.

I can replace this troublemaker for you. Drop me an e-mail with the request and I'll get the team on it Wednesday morning.

And I'm sorry for the failure. There's no excuse for this part substitution. There's nothing worse than sitting down to do some Propeller development when the silly adapter breaks and you don't have a backup.

Sincerely,

Ken Gracey

Graham

As a tip for use, I now recommend, and exclusively use, the thin retractable USB cable. The cable was first introduced with Penguin walking robots and is now being shipping with other Parallax products. The light weight cable does not appear to put any undue stress on the Propeller Plug when full unwound and the thin cable sets on the table without any tension.

Here's a tip for keeping track of your Prop Plug and increasing the odds of "not losing it." Keep it plugged into the end of the retractable USB cable. It then becomes a "large object" 5-inches long and your chances of losing it are lessened.

Here's a tip for plugging in and unplugging the Prop Plug. Use a steady grip on both the Prop Plug and the USB cable connector. Keeping this connected together makes it larger and more stable, easier to grip, thus more easy to handle and keep stabilized. The cable actually has a tiny grip pad molded into it on both sides which is very useful.

If you don't have the retractable cable, you definitely need to get one!

http://www.parallax.com/Store/Accessories/CablesConverters/tabid/166/CategoryID/40/List/0/SortField/0/catpageindex/2/Level/a/ProductID/37/Default.aspx

USB A to Mini B Retractable Cable

Item code 805-00010 $4.99

Type A to mini B; this portable cable extends and retracts making it ideal for portable use or when you need to make a temporary clutter-free connection. Cable length is 30 inches extended and 4 inches when retracted.

Key Specifications:

I don't.

I have a few of these thin retractable cables. With the "yo-yo" in the middle. Outwardly they all look the same.

Some of them work OK, others are very unreliable. Connection may work or it may not. May work with my XMOS board for example but not with my Prop Plug.

Others here have hinted at this kind of unreliability.

C.W.

ive got 3 or 4 of these and never had any problems! i dont use any thing else.