New Prop BOE?

NikosG

Posts: 705

NikosG

Posts: 705

Hello everybody!

Good news for all the robotic users!

A new PropBOE is in the pipeline from Parallax!

This BOE is expected to have similarities to the BoeBOT board, but also a lot of abilities as standard equipment!

It is said that this new BOE includes XBee socket, composite TV, Wifi socket, SD card, 4-ch A/D, audio amplifier output, and many other extras!

Parallax technicians are in the process to present this new board very soon!

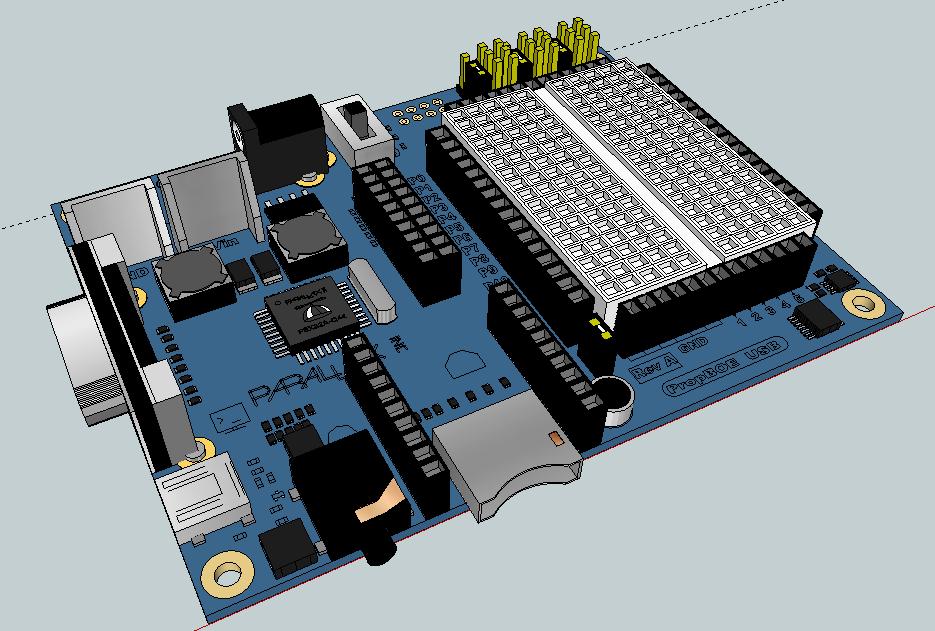

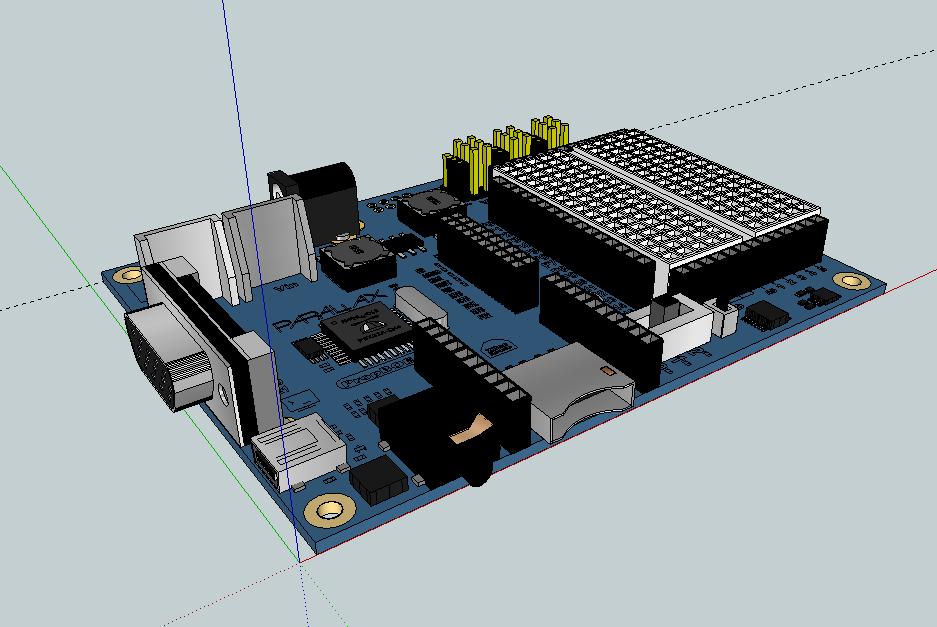

From a conversation I had with them, this new board probably looks like the following models.

Does anybody know more details?

Will it have a accompanying book with examples and activities?

Is the same board that uses the new amazing “S2- Propeller controlled ROBOT”?http://www.parallax.com/Store/Robots/AllRobots/tabid/755/ProductID/712/List/0/Default.aspx?SortField=ProductName,ProductName

Good news for all the robotic users!

A new PropBOE is in the pipeline from Parallax!

This BOE is expected to have similarities to the BoeBOT board, but also a lot of abilities as standard equipment!

It is said that this new BOE includes XBee socket, composite TV, Wifi socket, SD card, 4-ch A/D, audio amplifier output, and many other extras!

Parallax technicians are in the process to present this new board very soon!

From a conversation I had with them, this new board probably looks like the following models.

Does anybody know more details?

Will it have a accompanying book with examples and activities?

Is the same board that uses the new amazing “S2- Propeller controlled ROBOT”?http://www.parallax.com/Store/Robots/AllRobots/tabid/755/ProductID/712/List/0/Default.aspx?SortField=ProductName,ProductName

Comments

Most of the time Parallax doesn't talk about new products under design. They've been doing more talking recently, but you have to understand that these designs have to remain flexible until they're ready to manufacture in volume. There can be changes right up to the last moment. Features can be removed and occasionally features may be added until it's time to "get it out the door". I wouldn't be surprised if they're working on a Propeller BOE design. The list of features you mentioned is way too long for a BOE. Some of them might be planned add-ons, like the AppMods. The pictures you showed are nice concept layouts, but the two pictures are of slightly different layouts.

I'm sure the "What's a Microcontroller?" tutorial will eventually be rewritten for the new board, whenever it's done. I'm sure the Propeller Education Kit tutorials will be modified or rewritten for whatever replaces the Stamp BOE. The BOE is the heart of Parallax's educational efforts and the educational market is a major piece of Parallax's business.

We've been working with Nikos to develop some early models of this product for documentation, marketing and communication with distributors/customers who influence the design. I even asked him to put this board on the forums.

As you pointed out, it's a bit out-of-process for us to share details so early. But times are changing. Our thoughts are that if we work with our customers to evolve this board before it is produced we can speed the discovery of problems and expedite the product evolution so that Revision A is made for a long time without changes. Even a board like this has tooling - test fixtures, test processes, assembly jigs, etc. that are very expensive to change once we're underway.

There's more to this board than the hardware itself, as you know better than all of us. That's where the real investment lies - in the books and examples which give people a reason to use this board.

Thanks Mike and Nikos,

Ken Gracey

Some thoughts ...

It's a nice selection of I/O devices on the board. I assume the phono jack supplies both TV video and audio output like the Propeller Backpack does.

You might consider the store carrying a matching A/V cable with phono plugs for audio and for video to plug into a TV or video camera, possibly via a wireless link.

It looks like there might be a built-in microphone. Nice if true. I'd let you do a whole variety of audio and speech projects

BoeBot Basic ought to run on this with only some minor changes, mostly to I/O pin numbers. Obviously, it would be nice to explicitly support the ADC. It could use the xBee for a wireless console for control and data.

It looks like a nice platform for future educational offerings.

They keep well their secrets!

The only I know is, that this new Board has turned on my imagination, and it will be my "next step" on robotics!

@william chan - You really can't tell from the views shown of the board. I suspect not. You don't need level shifters for servos, maybe a series resistor. I've driven servos with just a 2.2K series resistor. That also works for 5V sensors.

@NikosG - If you don't want to wait to start, you can always take an existing USB BOEBOT and replace the Stamp with a SpinStamp. Alternatively, you can use a Propeller Protoboard with the Accessory Kit and add a microSD card and xBee socket as I did a few years ago. The microSD card socket was from SparkFun. The xBee socket isn't available any more, but the one now from Parallax would work just fine.

I want to second the suggestion for having a compatible cable available. There are several versions of 3 and 4 conductor cables out there so it would be nice to offer one that is known to work (ideally with the correct colors on the plugs (i.e., yellow for video)).

Please put pullups on both SDA and SCL.

I am worried about how many free pins are available. Hopefully the devices (mic, audio/video out, and especially the VGA) can be unselected. If the 2x10 female header is an AppMod header, don't bother since hardly any boards are made using that format. If it is to link to VGA, SD, audio, etc., I would recommend male headers and one could just use a shorting plug. Looking at my Professional Development Board I see that the female header could be used with jumper wire to Prop IO pins. That would be good since it wouldn't force you to use specific pins like the Demoboard does.

Servo headers need to be able to use both 5V and Vin.

This is an interesting board. I will probably buy one to replace the BOE with SpinStamp that I am currently using on a BOE Bot.

John Abshier

If each servo eats 500mA under load, 6 servos will need 3A, which will overwhelm the 5v regulator and cause a brown-out of the processor.

Even 3 servos will be a problem.

That's why I designed the Pub Bot to only use Vin for servos and the 3.3v regulator takes its input directly from the battery.

Just add two pads spaced .100" apart. Connect one lead to ground and the other to the /RESET line. That's it! Just that one small change of adding a couple more holes with traces to ground and reset. That's all I'm asking for. It shouldn't add any cost to the board. Don't worry about supplying the 2-pin header. Just add the holes for it.

Why?? Well with that small change I can easily just add a 2-pin header so I can connect a remote reset switch if I want to. Also, in some of my robots with multiple micros I want to be able to reset everything at once. If all of the boards had a 2-pin header like this I could easily wire everything up to handle it. In particular I have one large Propeller powered robot that I do this with. The actual reset switch on mine is going to some open collector buffers which will then in turn go to each of the devices I want to reset.

If each of the boards already had a spot for a 2-pin header it would make life much easier!

Robert

BTW: The appmod on the BOE shares the pinouts and if nothing is connected to it it doesn't use them it just uses board real estate.

Hopefully the Appmod connector will have level translators since most of the Appmod boards require 5V logic.

Give us a week or so and we'll share more details.

Thanks, Ken Gracey

Robert

Hello Mike,

I'm very glad to see another Mathematician in this forum!

You know, every time I plan a new project and then I order hardware from Parallax I worry if I have choosen all the necessary parts. I allways wonder " ...and if I need something else to complete my project?"

I think that the best advantage of this new BOE is that it will have all these abilities as a standard!!! So the board will be more friendly for me! (and for many other users I suppose)

And of course as a teacher I consider that a well-written accompanied book is essential!!!

The activities and the examples are for me equaly valuable as the haldware!

Nikos

We will use this board to start generating material for a new Propeller Educational Program. We will be releasing more material in open source format for this Propeller educational program, so I think its OK to open up our internal board specification/design process.

Even though I said open source, were not looking at completing this design as an open source community effort. At this point this approach would take too long and we dont have experience working this way yet. We will develop this board internally and release all finished and editable project files at the end, so we speed up the product release process and still leave the project open for future improvements or customer customization.

The specs below were developed based on the feedback we received from current customers and comments we read in the forums (we can add the reset connection you asked Robert :-) or received by PM, or email or via phone conversations and educational trade show meetings. The specs also take into account minimizing manufacturing costs trying to use a single board to cover most educational kits and applications (each board we generate involves a lot of setup fees for manufacturing which increases the retail price of ALL board variations made).

As you know, its not possible to deliver on all requests because sometimes the requests pull in opposite directions. For example, some people may ask for features that will price the board out of reach from many potential customers or could request adding a feature needed by a small group which will increase the retail price for everybody.

Talking about pricing, we just have a figure in the specs but the price can vary widely from this point on, depending on many factors, mainly on the features and components that make it to the final design. Pricing could be half or twice of what is in the specs so dont try to use this post to get a discount out of Jim or Ken if the board ends up costing $100. :-)

And you can also forget about the mention of the PropHWB. Based on experience were just trying to leave the door open for a board that could come up later (like the HWB came after the BOE in Stamps in Class) once the PropBOE becomes very popular. This board may or may not happen depending on many variables.

In education we need a stable platform that can stay in the market for a long period of time so educators can implement the hardware into their classes without having to redesign their curriculum (labs, Power Point presentations, etc) every year to catch up with revision changes. It takes time and effort to develop supporting documentation and a solid foundation allows that material to be useful for a longer period of time (as we did in Stamps in Class).

This PropBOE and the Propeller Education Program is not intended to replace the Stamps in Class (SIC) program based on the BASIC Stamp 2 microcontroller. While we work on this Propeller program were actually releasing two more SIC books by the end of this year. You also know about them since we posted most of the material in the forums already: Understanding Signals with the PropScope and SIC Mini-Projects. The new Propeller Education Program will be developed in parallel with Stamps in Class and it will have its own style for support and documentation, based on the years of experience (and feedback) gained from the SIC program. This new program wont involve porting SIC material into the Propeller, but generating brand new material that exploits the very unique and highly powerful features of the Propeller microcontroller.

I think that all of you prefer to receive this information and previews from upcoming Parallax products and I will continue disclosing information as long as nobody gets frustrated by too much information access. As Ken mentioned last week, were changing our approach since times are changing and were willing to search for a comfortable openness level.

As long as everybody understands the process and how reality and feedback will shape and change the project up to completion, we will be fine and I will continue sharing inside information all the way in our future hardware, software and documentation development process. If forum members get upset about this process, Ill pull back to a more standard corporate model where the development process is kept internal and well just bring the goodies out when theyre ready for prime time.

I believe this forum community is very mature, more like an extended Parallax family and all of you would rather have full access to all information now so you have a chance to make some requests and then youll enjoy even more the goodies when they come out.

Enjoy!

I also think it is a great idea to release the information early. It is very helpful to those that plan future projects around Parallax products.

Is it to early to release a projected release date? I am personaly going to put a project on hold till this board is realesed.

Thanks Ari and Ken

Hey Tony,

I think we may have met at UPEC, right?

We're starting the schematic design this week and I hope to have a prototype by early January. The manufacturing will be done in Rocklin, CA and the product will probably carry a lifetime guarantee from Parallax. I'm expecting to have these in stock no later than February.

Ken Gracey

Why some Parallax boards use Diptrace and some boards use Eagle?

Rich H

Several years ago I had to select a PCB layout + Schematic capture software that we would use in future open source designs for Parallax US Education Department projects and also as a platform for new designs made by Parallax Hong Kong Engineering team.

At the time, EAGLE was very popular with current Parallax customers and everybody certainly would appreciate if we could release all the files in a format they could open and modify, to speed up their project development. Even though we have paid EAGLE licenses we try to keep the designs inside the free EAGLE Light limitations so anyone can download, open and modify the files, even using a free license (as students do). If we need to go beyond the free version limitations, we can still share the files created with one of our EAGLE Standard licenses and anyone can still open and navigate the project files (but cannot save changes on files created this way unless they also have a paid license).

For education, EAGLE had the advantage of being able to run in any operating system. It runs in Windows, Linux and Mac platforms (Mac is popular in US schools and Linux is popular in European educational systems). For the Propeller Education Program we will do our best to support several Operating systems and EAGLE was a good fit.

All Parallax Hong Kong engineers have to use EAGLE (some of the files you already found at parallax.com website could be from PLX HK engineering) and for Parallax US educational program, we want to stick with EAGLE since we already have libraries developed and the operating system advantage I just mentioned.

Im not involved in managing Parallax US engineering, but I know that over time we used Protel 98, Protel 99, which were popular for a while until the Propeller came and everything started to move to PADs. I think somebody is using DipTrace and I heard nice comments about it in UPEW from Propeller customers but as far as I know it runs only in Windows and my staff doesnt have the library/work experience they developed with EAGLE.

For Parallax US its harder to stick with a single brand of PCB + Schematic software since some projects are very advanced and its more reliable and efficient to make those boards in PADs than in EAGLE or DipTrace (even with higher level licenses). Again, Im not in the loop of Parallax US engineering so for more details or accurate information we will need somebody else from Parallax US to confirm but I hope I still answered your question.

Recommendation noted.

In one of the internal revisions somebody asked to try to keep all connectors on one side of the PCB, trying to support enclosures better. You will notice that we tried to keep everything that needs a cable connected on the left side. We couldn’t fit everything there but we tried.

For the PropHWB tentative layout we recommended moving all the leftover connections/openings to the left following that goal to facilitate work with enclosures.

We will add the request to try to place the XBee headers so the XBee module wouldn’t be in the way. Not sure if there is going to be much room to move the headers up with the other headers right above the XBee, but we will certainly try during the PCB design.

Sorry for the late reply. Yes we did meet at UPEC and I enjoyed getting to speak with you very much.

Thanks for the info. What a quick production time. I will eagerly await their arrival. For now I will continue my work with a Spin Stamp on a BOE-BOT.

Thanks,

Tony

Here are the specifications for what will go inside each block:

- Propeller, EEPROM crystal, and reset button

- The I2C pull-up resistors are in this block.

- The EEPROM is 64Kx8, for storing non-volatile data that is not affected by programming.

- A 5 MHz crystal is soldered in place.

- Vin power

- A dual-output switching regulator will provide 5.0 and 3.3 volt supplies.

- Power can be input through a barrel-jack connector or a 9-volt battery, which will be mechanically and electrically interlocked.

- Power outputs can be disabled by pulling a power enable pin low.

- A power good output for the 5-volt line will allow the USB power controller to know when it can switch off USB power.

- An auxiliary 5-volt line can be disabled by pulling an auxiliary power enable pin low.

- Power switch and LEDs

- A single-pole triple-throw switch selects between off, on, and on plus auxiliary.

- Auxiliary power is only drawn from the Vin supply, not from USB.

- LEDs indicate the state of the 3.3 V supply and the auxiliary power supply.

- USB power and data

- An FT232R converts a USB conenction to serial.

- The 5 V supply is current limited to 500 mA, to keep current draw within USB requirements.

- The 5 V supply is controlled by the /PWREN pin from the FTDI controller, including a filter to remove noise from the FT232R.

- The 5 V supply will switch off when a valid 5 V output is present from the Vin Supply.

- The signals should all be high impedance when the USB port is disconnected.

- There should be no negative effects when outputs are externally driven to Vss or 3.3 V.

- All data and flow control lines are shared with the Serial/WiFi/PropPlug socket or header.

- VGA circuitry with LEDs

- LEDs will be present for all connections at either the VGA connector or the multi-purpose socket.

- A low-profile VGA connector may be used if space is limited.

- ADC and microphone

- Three or more analog inputs, plus a microphone, are connected to an I2C ADC.

- The ADC is powered from, and referenced to, the 5 V supply, but the I2C pins are pulled up to 3.3 V.

- DAC filter and amplifier with LEDs

- Two PWM pins from the Propeller are filtered and buffered before connecting to two analog outputs with a 0 to 5 V range.

- The filter may be in the buffers feedback loop.

- Two LEDs are either connected directly to the I/O pins or buffered through a digital buffer.

- MicroSD card

- The MISO, MOSI, CS, and CLK lines are connected directly to the Propeller.

- Remaining pins will be available as surface-mount solder pads on the underside of the PCB.

- XBee socket

- All serial data and flow control pins, as well as associate and reset are connected to the multi-purpose socket.

- Remaining pins will be available as surface-mount solder pads on the underside of the PCB.

- Servo-style headers and jumpers

- Three pairs of jumpers provide 6 ports.

- Power can be selected between Vin and auxiliary (5 V) power, for a given pair.

- Voltage select jumpers will use metric spacing to avoid confusion with headers.

- Serial/WiFi/PropPlug socket or header

- The WiFi module pins should be high impedance when not powered, and it should draw power from the DCD pin.

- The WiFi module should have no negative effects when its outputs are indefinitely driven to Vss or 3.3 V.

- A 2x8 header or socket will provide all of the signals of a DB-9 connector, except for RI.

- All data and flow control lines, except DCD, are shared with the USB port.

- DCD will provide +3.3 V power when the USB port is not in use.

- This will turn off the WiFi module whenever the USB port is available.

- Multi-purpose Socket

- All VGA connections are only connected to this header and a set of LEDs.

- The LEDs may be either at the VGA connector or this socket.

- The XBee Din and Dout pins, and possibly other XBee pins, should have indicator LEDs.

- The Serial/WiFi/USB flow control pins are available from this connector.

- The Propeller reset line is available from this connector.

- The Propeller XI line is available from this connector, for external clocking.

- Breadboard headers

- The headers will surround the same breadboard as the BOE.

- Vin will not be present, but 3.3 and 5 V will be.

- Ground will be in the lower left corner.

- Headers along the left side of the breadboard connect to the 16 lower bits of the Propeller's 32-bit I/O port.

- These I/O pins are not used elsewhere

- Analog inputs and outputs are in the lower right corner

The core of the design is completed, but we may still make changes as we flesh out the blocks. If you have any compelling suggestions, let us know in case we missed anything. We did consider a lot more than what is present in the current design, but we wanted to avoid sharing I/O pins whenever possible, and there is a limited amount of PCB space, so not every feature that we desired made it into the design.We will spend the next several weeks creating the schematics for each block, selecting components, and laying out the board. We will keep everyone up to date, and whenever possible we will convert files to DipTrace and post those files too.

David Carrier

Parallax Inc.

First key point:

Am I reading it right, that if you have USB plugged in (like programming via prop tool and using PST) that you can't use WiFi? How are you supposed to test and debug your WiFi code? Also, it's not clear, but does the Xbee being plugged in preclude doing VGA or WiFi? You talk about a lot of the pins being on both ports. I think this would be really unfortunate... I understand that we don't want to use up all the I/O pins on the Prop, and that you want to allow for using the WiFi for doing the serial communication and/or programming wirelessly instead of being wired. However, what if I want to use the WiFi module to do something else? How can I debug it without having the USB plugged in? I think because you are giving them a lot of peripherals, you can use up more of the prop pins.

I think you should be able to use VGA, XBee, WiFi, SD card, ADC, and USB at the same time. Maybe Xbee and WiFi could be mutually exclusive, but all the others should be independent. Perhaps you need switches or jumpers to move the WiFi to alternate pins? Then you get both features. Using WiFi in place of the USB cable, and using WiFi for whatever on another port at the same time as USB for programming/debugging.

I think it's okay to have less free I/O pins when you have so many built in peripherals. Obviously, if they don't have stuff plugged into the optional slots, then it would be nice if those pins were usable for other things. I just think that making a lot of peripherals mutually exclusive is a bad idea.

Second key point:

Since this is an education board, are you sure you want to have surface mount solder pads on the bottom of the board that require soldering to get at the extra pins? Those should be on headers on the top of the board so you can jumper them over to the breadboard area or free prop port pins. I don't think teachers are going to want kids soldering up the boards, when they want to use them for the next class. This seems like a big mistake to me.

Roy

The WiFi module connects directly to P30 and P31 on the Propeller and the DTR pin is buffered to RESn. These are the connections needed to reprogram the Propeller, which is the primary purpose of the WiFi module. Since these are the same pins the USB port is using, only one will work at a time.

The program on the PropBOE will not generally know whether it is using the WiFi module or the USB port. The Propeller Tool can send new programs through either connection, and you can debug with the PST over the USB port or with a telnet program over WiFi. If you set the WiFi module to use the same baud rate as the PST, the same code will work with both. We may also directly add WiFi support to the PST.

If you want to use the WiFi module at the same time as the USB port, you can connect it using power and I/O pins from the sockets near the breadboard. This would allow you to send and receive data on another set of I/O pins, but it would prelude you from reprogramming the Propeller over WiFi.

There are no direct connections between the VGA port or the XBee module and the Propeller; you would need to jumper a connection between the multi-purpose socket and the 16 I/O pins alongside the breadboard. There are plenty of pins to use both at the same time. The SD Card and DAC are always connected to the Propeller and can be used no matter what else you are using. The ADC is attached to the same I2C bus as the EEPROM, so there is a limited amount of bandwidth to share between the two.

As for the surface mount solder points, they are only for connections that would not otherwise be available. (i.e. there isn't enough room for more headers) Instead of leaving them completely inaccessible, we are planning to provide surface-mount solder points. They are not near as useful as headers, but we just don't have room for more headers. This way, instead of soldering jumper wires directly to the pins on the SD card socket or the Propeller microcontroller, advanced users can at least solder to the surface-mount pads.

David Carrier

Parallax Inc.

Bad assumption: "WHO" says the primary purpose for the WiFi is to reprogram the propeller? As a user, "MY" primary purpose for WiFi would be communication with a robot or data gathering instrument.

And this is supposed to be easy to get set up in an educational setting?

I'm fuzzy here, if the WiFi is set up to use the programming pins, how do we grab other power and I/O pins?

As both a user and an educator, this is really getting weird. Some peripherals are handled with a "hard wired" philosophy, others with a "use a jumper: philosophy. This makes life a little more fun than I like to have with students (4H in my case).

I'm with Roy on this, find a way to add more headers, even if it means changing the footprint of the board.

Thanks,

Tony

Any word on the progress of this product?

Thanks,

Tony