A Carrier Board for the Parallax Propeller Servo Controller

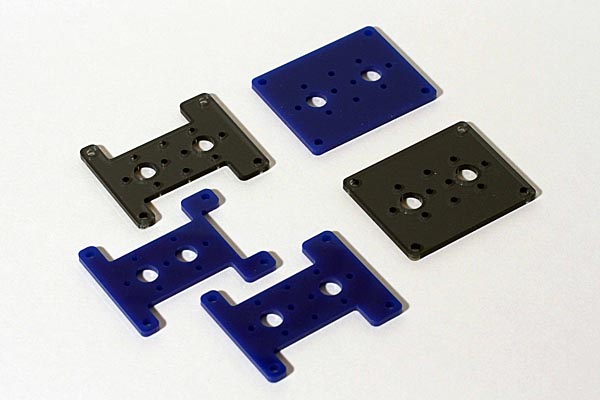

I’ve designed a set of carrier boards for the Parallax Propeller Servo Controller USB. I’ve attached some pictures as well as several versions of the drawings that were used to create them. I had these laser cut out of 3mm acrylic (“plexiglass”) which is similar to that used in the new cases from Parallax. I had mine cut by Pololu ( www.pololu.com ). If you want to make your own boards, any of the drawing files should be sufficient for most places to cut them (or to cut them yourself if you have access to a laser cutter). I expect you could also use the drawings to machine the plates instead of laser cutting them. Of course, they can also be used as templates to make the plates by hand.

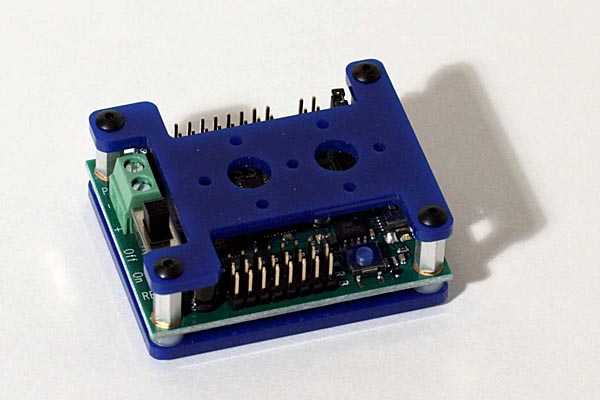

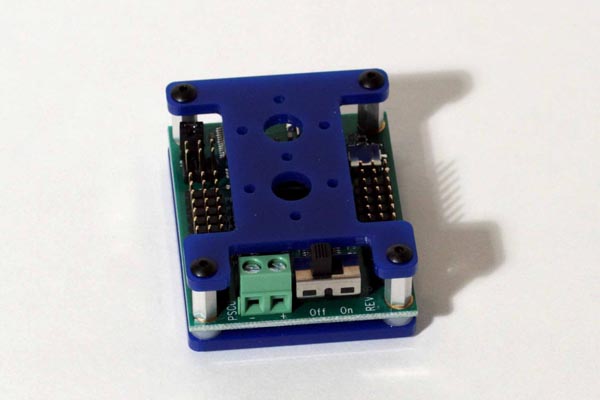

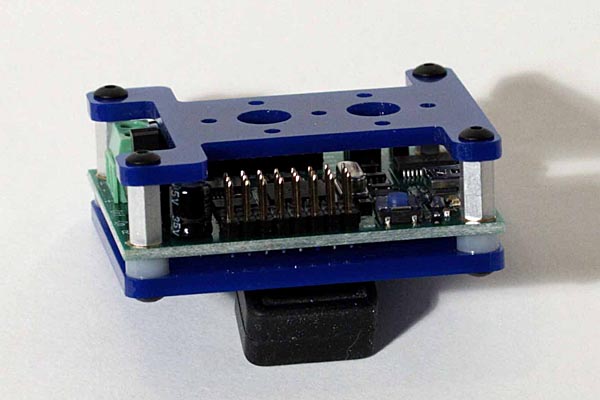

There are three types of plates. Two of them have cutouts so that they can be mounted on the component side of the board without covering the servo headers, reset button, etc. One of these also has a cutout on one end to clear the input power terminal and power switch. This allows the plate to be mounted closer to the board – the highest components that still need to be cleared are the servo power capacitors (which measure about 5/16” above the pc board in my examples). You need standoffs a little larger than this (or some added washers) if you don’t want to feel like you are crushing the capacitors. The board without the end cutout on the end would need to be mounted a little higher.

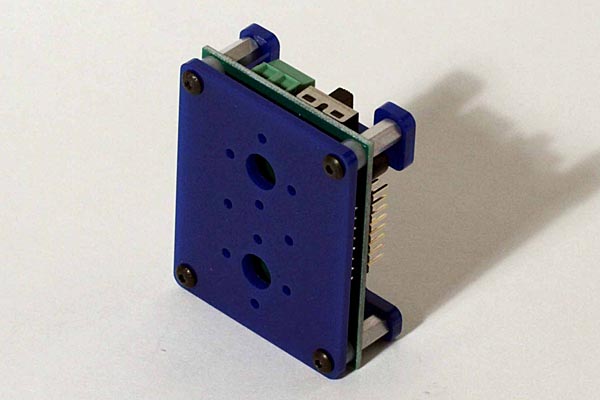

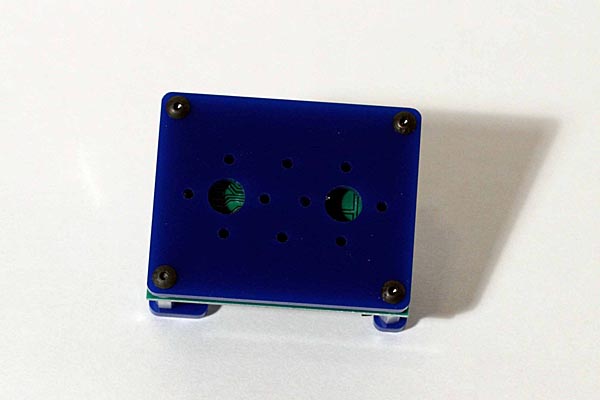

Both of the boards with cutouts can also be mounted on the bottom of the pc board to provide a protective cover or a base for mounting to something else. Because of the cutouts, they will leave some areas exposed. The third carrier board design has no cutouts at all and is primarily designed to be used as a base plate or protective cover for the bottom of the board. A combination of plates on the bottom and component sides of the board will create a minimalist “case” for the servo controller.

Standard standoffs and other hardware are used to attach the carrier plates to the board. I’ve been using 4-40 hardware with threaded and non-threaded standoffs.

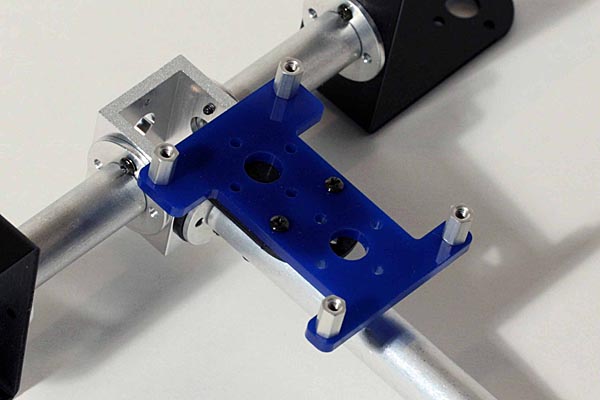

The holes in the carrier plates (other than the board mounting holes) are based on the pattern used by the Servo Erector Set parts from Lynxmotion ( www.lynxmotion.com ). Other hole patterns can be drilled in the plates if desired – or the drawings can be changed and parts can be cut to exact specifications. I chose to use this particular pattern because I have a use for it and it’s more complicated to drill by hand and get the hole locations exactly to spec than other patterns are.

I have attached quite a few pictures – although most of them are just different views of the same hardware. Somehow, I neglected to take pictures that show the boards that don’t have the end cutout being used. I have had parts cut in two different material colors – smoke grey and translucent (not transparent) blue. Several of the pictures show the plates with or without the servo controller mounted to Lynxmotion hardware.

The three drawing files are based on the same original drawing but are in three different formats. The DWG and DXF files follow Autocad (R14) standards and can be read by many programs (and can probably be used directly by most places that will laser cut parts). The PDF file is a standard Acrobat PDF file.

I have created similar boards for the Gadget Gangster Propeller Platform and those are described in this thread:

http://forums.parallax.com/showthread.php?t=127219

Update on cost:

As mentioned above, I had these cut by Pololu. They describe the cost structure on their web site but basically you pay for the time it takes to cut and for the materials. I don't have a breakdown for what each board would cost since the cutting time for each will be a little different and I ordered them together. The cost will also vary depending on the material. I expect each of these boards would run from under $1.50 to around $2.50 each depending on style and material (not including shipping). Pololu has a $25.00 minimum on laser cutting orders.

The turnaround from Pololu is usually pretty quick. I've received orders shipped USPS from Nevada to Ohio two days after I accepted their quote. Other orders have taken a few days longer.

I also neglected to mention that my board design is definitely inspired by the electronics carrier board that Lynxmotion sells:

http://www.lynxmotion.com/p-501-ses-electronics-carrier.aspx

There are three types of plates. Two of them have cutouts so that they can be mounted on the component side of the board without covering the servo headers, reset button, etc. One of these also has a cutout on one end to clear the input power terminal and power switch. This allows the plate to be mounted closer to the board – the highest components that still need to be cleared are the servo power capacitors (which measure about 5/16” above the pc board in my examples). You need standoffs a little larger than this (or some added washers) if you don’t want to feel like you are crushing the capacitors. The board without the end cutout on the end would need to be mounted a little higher.

Both of the boards with cutouts can also be mounted on the bottom of the pc board to provide a protective cover or a base for mounting to something else. Because of the cutouts, they will leave some areas exposed. The third carrier board design has no cutouts at all and is primarily designed to be used as a base plate or protective cover for the bottom of the board. A combination of plates on the bottom and component sides of the board will create a minimalist “case” for the servo controller.

Standard standoffs and other hardware are used to attach the carrier plates to the board. I’ve been using 4-40 hardware with threaded and non-threaded standoffs.

The holes in the carrier plates (other than the board mounting holes) are based on the pattern used by the Servo Erector Set parts from Lynxmotion ( www.lynxmotion.com ). Other hole patterns can be drilled in the plates if desired – or the drawings can be changed and parts can be cut to exact specifications. I chose to use this particular pattern because I have a use for it and it’s more complicated to drill by hand and get the hole locations exactly to spec than other patterns are.

I have attached quite a few pictures – although most of them are just different views of the same hardware. Somehow, I neglected to take pictures that show the boards that don’t have the end cutout being used. I have had parts cut in two different material colors – smoke grey and translucent (not transparent) blue. Several of the pictures show the plates with or without the servo controller mounted to Lynxmotion hardware.

The three drawing files are based on the same original drawing but are in three different formats. The DWG and DXF files follow Autocad (R14) standards and can be read by many programs (and can probably be used directly by most places that will laser cut parts). The PDF file is a standard Acrobat PDF file.

I have created similar boards for the Gadget Gangster Propeller Platform and those are described in this thread:

http://forums.parallax.com/showthread.php?t=127219

Update on cost:

As mentioned above, I had these cut by Pololu. They describe the cost structure on their web site but basically you pay for the time it takes to cut and for the materials. I don't have a breakdown for what each board would cost since the cutting time for each will be a little different and I ordered them together. The cost will also vary depending on the material. I expect each of these boards would run from under $1.50 to around $2.50 each depending on style and material (not including shipping). Pololu has a $25.00 minimum on laser cutting orders.

The turnaround from Pololu is usually pretty quick. I've received orders shipped USPS from Nevada to Ohio two days after I accepted their quote. Other orders have taken a few days longer.

I also neglected to mention that my board design is definitely inspired by the electronics carrier board that Lynxmotion sells:

http://www.lynxmotion.com/p-501-ses-electronics-carrier.aspx

Comments

Perhaps mctrivia may comment on the RepRap idea???

Thanks.

I updated the first post to include the cost for having the boards made by Pololu.