BASIC Stamp DEV boards based on OEM chips and SX28/48 Protoboards

RobotWorkshop

Posts: 2,307

RobotWorkshop

Posts: 2,307

Introduction

If you like working with the Parallax BASIC Stamps this will help with some options for building your own Stamp on a budget and you'll have the satisfaction of building it yourself. By using OEM components you can build a real Stamp development board for a bit less than buying a Stamp module and carrier board.

The anatomy of a BASIC Stamp.

“A BASIC Stamp is a single-board computer that runs the Parallax PBASIC language interpreter in its microcontroller. The developer's code is stored in an EEPROM, which can also be used for data storage. The PBASIC language has easy-to-use commands for basic I/O, like turning devices on or off, interfacing with sensors, etc. More advanced commands let the BASIC Stamp module interface with other integrated circuits, communicate with each other, and operate in networks.”

At the lowest level only a few parts needed to make a functional Stamp. You need the OEM BASIC Stamp Interpreter chip, an I2C EEPROM chip to hold the tokenized BASIC program, a resonator for a clock source, and a few caps and resistors. If you don't have a stable 5V supply then you'll also need a voltage regulator to supply the power for the module. For programming a few more components are required for a serial connection but can otherwise be left off once your BASIC Stamp program has been downloaded into the EEPROM chip.

Making our own Stamp using OEM parts.

This project is possible since Parallax offers their pre-programmed OEM Stamp Interpreter chips for sale separately. The OEM chip has Parallax’s own propriety Interpreter already programmed into the chip which sets them apart from the plain microcontroller chip and why they cost a few dollars more. We can use this as the basis and add the rest of the parts like the EEPROM, resonator, etc as the foundation for our own custom Stamp board.

Getting a head start using Parallax SX28/48 Protoboards!

If you look at the BASIC Stamps you will see that the most current and more powerful versions are based on an SX28 or SX48 microcontroller chip. We can use any one of these OEM BASIC Stamp chips for this project. A simple way to keep them straight is that any of their chips that start with a BS2 are programmed with their BASIC Stamp Interpreter and the plain SX28 and SX48 chips are not. Those are normally programming in assembly or SX/B (compiled BASIC) and loaded directly into the flash on the SX chips. The BASIC Stamps have the PBASIC Interpreter programmed into the flash by Parallax and store your tokenized PBASIC program in the EEPROM chip connected to the OEM Stamp chip.

The SX28 and SX48 protoboards can make a perfect foundation for building a custom Stamp module with OEM parts. Half the work is already done! All we have to do are a few things that Parallax probably never intended. The first is to replace the SX28/SX48 processor with the equivalent version of a pre-programmed OEM Stamp from Parallax. Then add a few parts like the EEPROM and make a few small modifications to the board.

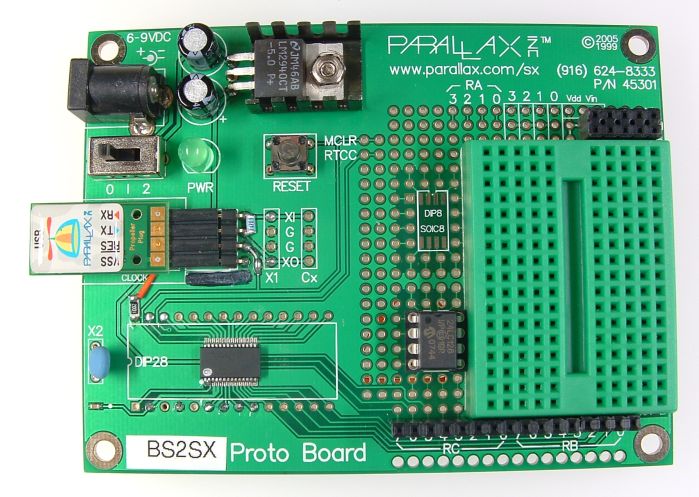

Attached are a couple pictures of finished boards using a BS2SX OEM chip and a BS2p40 OEM chip. The following posts will explain how each one was created.

NOTE: The BS2SX is programmed by Parallax into an SX28 chip. For certain this has caused some confusion to customers and many get the SX28 and BS2SX mixed up. Other than having 'SX' in the name keep in mind they are different chips. One has the BASIC Interpreter programmed into the firmware and the plain SX28 does not.

If you like working with the Parallax BASIC Stamps this will help with some options for building your own Stamp on a budget and you'll have the satisfaction of building it yourself. By using OEM components you can build a real Stamp development board for a bit less than buying a Stamp module and carrier board.

The anatomy of a BASIC Stamp.

“A BASIC Stamp is a single-board computer that runs the Parallax PBASIC language interpreter in its microcontroller. The developer's code is stored in an EEPROM, which can also be used for data storage. The PBASIC language has easy-to-use commands for basic I/O, like turning devices on or off, interfacing with sensors, etc. More advanced commands let the BASIC Stamp module interface with other integrated circuits, communicate with each other, and operate in networks.”

At the lowest level only a few parts needed to make a functional Stamp. You need the OEM BASIC Stamp Interpreter chip, an I2C EEPROM chip to hold the tokenized BASIC program, a resonator for a clock source, and a few caps and resistors. If you don't have a stable 5V supply then you'll also need a voltage regulator to supply the power for the module. For programming a few more components are required for a serial connection but can otherwise be left off once your BASIC Stamp program has been downloaded into the EEPROM chip.

Making our own Stamp using OEM parts.

This project is possible since Parallax offers their pre-programmed OEM Stamp Interpreter chips for sale separately. The OEM chip has Parallax’s own propriety Interpreter already programmed into the chip which sets them apart from the plain microcontroller chip and why they cost a few dollars more. We can use this as the basis and add the rest of the parts like the EEPROM, resonator, etc as the foundation for our own custom Stamp board.

Getting a head start using Parallax SX28/48 Protoboards!

If you look at the BASIC Stamps you will see that the most current and more powerful versions are based on an SX28 or SX48 microcontroller chip. We can use any one of these OEM BASIC Stamp chips for this project. A simple way to keep them straight is that any of their chips that start with a BS2 are programmed with their BASIC Stamp Interpreter and the plain SX28 and SX48 chips are not. Those are normally programming in assembly or SX/B (compiled BASIC) and loaded directly into the flash on the SX chips. The BASIC Stamps have the PBASIC Interpreter programmed into the flash by Parallax and store your tokenized PBASIC program in the EEPROM chip connected to the OEM Stamp chip.

The SX28 and SX48 protoboards can make a perfect foundation for building a custom Stamp module with OEM parts. Half the work is already done! All we have to do are a few things that Parallax probably never intended. The first is to replace the SX28/SX48 processor with the equivalent version of a pre-programmed OEM Stamp from Parallax. Then add a few parts like the EEPROM and make a few small modifications to the board.

Attached are a couple pictures of finished boards using a BS2SX OEM chip and a BS2p40 OEM chip. The following posts will explain how each one was created.

NOTE: The BS2SX is programmed by Parallax into an SX28 chip. For certain this has caused some confusion to customers and many get the SX28 and BS2SX mixed up. Other than having 'SX' in the name keep in mind they are different chips. One has the BASIC Interpreter programmed into the firmware and the plain SX28 does not.

Comments

The most difficult aspect of this project is installing the OEM Interpreter chip. There is one method I have found works very well for fine pitch parts. I use a sharp utility knife to cut the leads right at the body of the part. It requires a steady hand since you only want to sever the lead without nicking the PCB. That may not be a problem if there are no traces underneath the chip but it is always best to assume there are and be very careful during the process. The example photograph shows the removal of an SX28 processor. Since the leads were thin I only needed to cut one side and then bend the chip up and down to break off the other side. With the chip out of the way the preparation was easy. Just put a fresh bead of solder down with the iron and all the leads end up sticking to the soldering iron. Just wipe them off on your sponge. The last step is two go over the pads with solder wick so they are all flat again ready for the installation of the new chip.

The alignment of the parts is critical. Before installing a surface mount component apply a small amount of solder to one (and only one) of the pads on the PCB where the part is going to be installed. Then while warming the solder on that pad use the tweezers to set the part in place. If the alignment isnt right you can do adjustments while the solder is still molten. If it takes too long, let the solder cool to ensure the part is not damaged by excessive heat. Once cool the joint can be warmed up again and the alignment can be adjusted until it is perfect. Before soldering any other joints on the part use the magnifying glass to verify that the alignment is ok. The exact orientation of the part in relation to the pads is what were concerned with. Next, go ahead and solder an opposing lead on the part. As long as everything looks good continue soldering each one. I usually go back and re-solder the first pin since it may be messed up from re-positioning the part.

For the modifications to the PCB just refer to the appropriate PCB layout which shows what traces need to be altered. Here are the step by step instructions to build up a BS2SX on an SX28 protoboard using the parts from the list. Alternately you should be able to use the OEM BS2E chip as well since that is based on the SX28.

• Remove/Replace Microcontroller with BS2SX OEM chip

• Remove 3-pin SIP at location X2 and install 50Mhz resonator in its place (or just plug in)

• Remove two 4-pin SIP sockets (locations X1 and CX) and solder at either DIP/SOIC location in the breadboard area to create an 8-pin DIP socket for the I2C EEPROM.

• Wire up ground leads and 5V power to 8-pin DIP socket for EEPROM

• Add bypass cap to DIP socket for EEPROM across ground and 5V supply

• Wire up SCL and SDA lines to EEPROM

• Add pull up resistor on EEPROM SDA line

• Solder bridge RTCC lead to gound

• Cut traces at SX-Key header that went to OSC lines

• Add loopback resistor at 4-pin header

• Add Diode, pullup resistor on reset line

• Add SIP headers on ports

• Install solderless breadboard (Stick on)

• Install EEPROM chip in 8-pin DIP socket

BS2SX Protoboard (based on SX28 Protoboard)

1 - SX28 Protoboard Part# 45302

1 - BASIC Stamp BS2SX Interpreter Chip Part# PBASIC2SX-28SS (This part is only available from Parallax!)

1 - 16K Byte EEPROM (8-pin DIP format) Part# 602-00013

1 - 50.00 MHz resonator (through hole version) Part# 250-05060

2 - 4.7K ohm resistors – 1206 surface mount preferred

2 - 10K ohm resistors – 1206 surface mount preferred

1 - 1n4148 small signal diode

1 - .1μf capacitor – 1206 surface mount preferred

1 - 8-pin DIP socket for EEPROM (or unsolder two 4-pin SIP sockets)

1 - Solderless breadboard Part# 700-00012

2 - 16-pin SIP socket Part# 450-01601

1 - 7.5 VDC, 1 amp power cube Part# 750-00009

1 - PropPlug w/cable (used for multiple boards – one time expense) Part# 32201

Misc wire (solid telephone or wire wrap)

For the modifications to the PCB just refer to the appropriate PCB layout which shows what traces need to be altered. Here are the step by step instructions to build up a BS2p40 on an SX48 protoboard using the parts from the list. Alternately you couldbe able to use the OEM 2p24, 2pe, or 2px chips instead since those are based on the SX48. You'll just be limited to 16 I/O with those chips unlike the BS2p40 which has 32 I/O.

• Remove/Replace Microcontroller with BS2p40 OEM chip

• Remove 3-pin SIP and install 20Mhz resonator in its place (or just plug in)

• Remove two 4-pin SIP sockets (locations X1 and CX) and solder at either DIP/SOIC location in the breadboard area to create an 8-pin DIP socket for the I2C EEPROM.

• Wire up ground leads and 5V power to 8-pin DIP socket for EEPROM

• Add bypass cap to DIP socket for EEPROM across ground and 5V supply

• Wire up SCL and SDA lines to EEPROM

• Add pull up resistor on EEPROM SDA line

• Solder bridge RTCC lead to gound

• Cut traces at SX-Key header that went to OSC lines

• Add loopback resistor at 4-pin header

• Add Diode, pullup resistor on reset line

• Add SIP headers on ports

• Install solderless breadboard (Stick on)

• Install EEPROM chip in 8-pin DIP socket

BS2p40 Protoboard (based on SX48 Protoboard)

1 - SX48 Protoboard Part# 45300

1 - BASIC Stamp BS2p40 Interpreter Chip Part# PBASIC48W/P40 (This part is only available from Parallax!)

1 - 16K Byte EEPROM (8-pin DIP format) Part# 602-00013

1 - 20.00 MHz resonator (through hole version) Part# 250-02060

2 - 4.7K ohm resistors – 1206 surface mount preferred

3 - 10K ohm resistors – 1206 surface mount preferred

1 - 1n4148 small signal diode

1 - .1μf capacitor – 1206 surface mount preferred

1 - 5.1pf capacitor – 1206 surface mount preferred

1 - 8-pin DIP socket

1 - Solderless breadboard Part# 700-00012

3 - 16-pin SIP socket Part# 450-01601

1 - 7.5 VDC, 1 amp power cube Part# 750-00009

1 - PropPlug w/cable (used for multiple boards – one time expense) Part# 32201

Misc wire (solid telephone or wire wrap)

RobotWorkshop (Author’s web site)

http://www.robotworkshop.com

Parallax Website:

http://www.parallax.com/

Tutorials about Surface mount soldering on SparkFun.

http://www.sparkfun.com/commerce/tutorials.php

Surface Mount tutorial

http://www.tutorialsweb.com/smt/smt.htm

Website with excellent BASIC Stamp information

http://www.emesystems.com/BS2index.htm