Another plywood bot

As I mentioned in this thread, my intention was to build a larger bot. I've accomplished a few of my goals and wanted to post the progress.

http://forums.parallax.com/showthread.php?t=122480

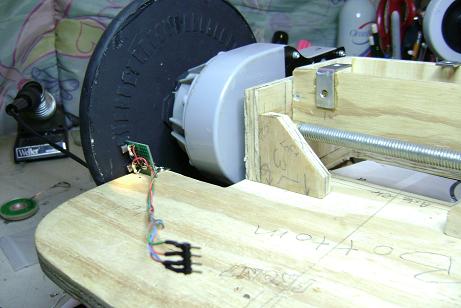

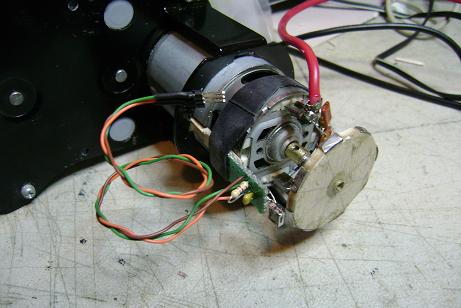

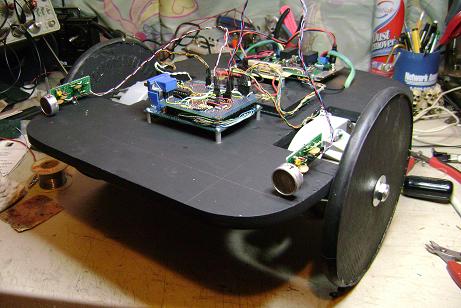

I've built the bot, another plywood creation, with motors from a childs riding toy. I wanted to use hall effect quadrature encoders mounted on the wheels, but I couldnt get the components cut and placed accurately enough for the resolution I wanted. I ended up mounting tach style encoders on the motors, which was a battle itself with a cheap drill press and bandsaw. I was able to get a simple RF pair from Sparkfun to work sending commands from the bot to the beacons. Another battle was how to detect bot heading without IR. I went round and round trying to use sonar but just couldn't find the right materials or techniques to focus the beam. It finally occurred to me to use to two transducers on the bot measure the differential distance. Then I had to overcome the effects of the interference created by the RF on the transducers and that of the motors to the RF.

I finally got a simple zero radius turn maneuver to detect the direction of, and the beacon-to-bot distance. Now on to navigating and docking to a charging station.

agfa

http://forums.parallax.com/showthread.php?t=122480

I've built the bot, another plywood creation, with motors from a childs riding toy. I wanted to use hall effect quadrature encoders mounted on the wheels, but I couldnt get the components cut and placed accurately enough for the resolution I wanted. I ended up mounting tach style encoders on the motors, which was a battle itself with a cheap drill press and bandsaw. I was able to get a simple RF pair from Sparkfun to work sending commands from the bot to the beacons. Another battle was how to detect bot heading without IR. I went round and round trying to use sonar but just couldn't find the right materials or techniques to focus the beam. It finally occurred to me to use to two transducers on the bot measure the differential distance. Then I had to overcome the effects of the interference created by the RF on the transducers and that of the motors to the RF.

I finally got a simple zero radius turn maneuver to detect the direction of, and the beacon-to-bot distance. Now on to navigating and docking to a charging station.

agfa

Comments

Handmade wheels? How did you get them so nice & true with just hand tools?

Great bot! You need to join and post your pics in the DIY Robot Group.

Those look like Power Wheels motors - is that right?

Thanks for your comments.

The wheels werent that hard. I first trued my drill press as best I could. I laid out and rough-cut the wheels on the bandsaw, and drilled the center hole. I used a home made jig inspired by Norm Abram to do the final circle cut. I used a router to cut the round over. I epoxied a brass tube in the center, while the epoxy dried I free-wheeled it on a shaft and aligned by eye. I finished by gluing on a tire made of a strip of inner tube.

Ive used plywood wheels on the last two bots Ive made. I am quite pleased with the cost and the freedom it provides in the design process.

Whit,

Thanks for the invitation, I've got lots of pics.

I'm not sure about the motors, I didnt pay attention. It was an ATV style toy that I found out by someones trash can. I tore the motors out and tested them as soon as I got home. It was a good day!

agfa

Humanoido

http://www.youtube.com/watch?v=uO8HODd7ZgU

It does run straight as an arrow too!