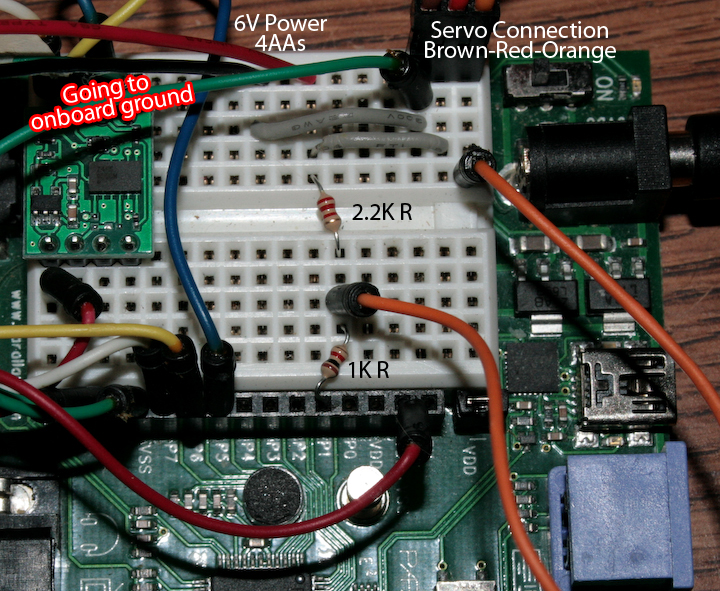

Voltage divider to pull-up servo logic line

I am having trouble getting a servo to work. It responds after about 40 seconds when the control

pin is wired straight to the propeller pin.

I am trying a voltage divider to pull up the signal, but I seem to be getting even less "juice" in. Not

pictured but I placed an led on the control line and it is dimmer with this set-up then wired

directly to the propeller pin.

What am I doing wrong?

I got the resisters a while back at radio shack in a pack. I think they were listed as 1/4w. I am

thinking I am reading the color codes wrong or maybe I am wiring it wrong.

Post Edited (Thomas Fletcher) : 6/3/2010 3:15:11 PM GMT

pin is wired straight to the propeller pin.

I am trying a voltage divider to pull up the signal, but I seem to be getting even less "juice" in. Not

pictured but I placed an led on the control line and it is dimmer with this set-up then wired

directly to the propeller pin.

What am I doing wrong?

I got the resisters a while back at radio shack in a pack. I think they were listed as 1/4w. I am

thinking I am reading the color codes wrong or maybe I am wiring it wrong.

Post Edited (Thomas Fletcher) : 6/3/2010 3:15:11 PM GMT

Comments

BTW, I never use a resistor or pullups on my servos. I will use a 5K inline with the control signal when using the Propeller Servo Controller Board because of the Voltage Translators.

a camera stabilization platform. The program is suppose to counter rotate the platform

in response to roll angle.

Video

www.facebook.com/profile.php?id=830440549&v=app_2392950137#!/video/video.php?v=451426750549

Still can not figure out the start-up delay or why it sometimes just stops working.

CON _clkmode = xtal1 + pll16x _xinfreq = 5_000_000 CLKPIN = 7 DATAPIN = 6 CSPIN = 5 X_OFFSETVAL = 28 ' X-Axis offset compensation value Y_OFFSETVAL = 36 ' Y-Axis offset compensation value Z_OFFSETVAL = -138 ' Z-Axis offset compensation value VAR { long _X,_Y,_Z,_OldX,_OldY,_OldZ long Z_Rot_Angle, Old_Z_Rot_Angle long Y_Rot_Angle, Old_Y_Rot_Angle long X_Rot_Angle, Old_X_Rot_Angle } long Stack[noparse][[/noparse]16], x, y, servopos, loaded OBJ DEBUG : "Parallax Serial Terminal" SPI : "MMA7455L_SPI_v2.spin" 'Used to Communicate to the Accelerometer servo : "Servocontrol" Pub Init 'Initialize the acceleromter SPI.start(CLKPIN, DATAPIN, CSPIN) DEBUG.start(250000) servo.init waitcnt(clkfreq/10+cnt) 'Wait for things to settle for a 1/10th of a sec SPI.write(SPI#MCTL, (%0110 << 4)|(SPI#G_RANGE_2g << 2)|SPI#G_MODE) 'Initialize the Mode Control register 'Write the X, Y, and Z offset compensation values SPI.write(SPI#XOFFL, X_OFFSETVAL) SPI.write(SPI#XOFFH, X_OFFSETVAL >> 8) SPI.write(SPI#YOFFL, Y_OFFSETVAL) SPI.write(SPI#YOFFH, Y_OFFSETVAL >> 8) SPI.write(SPI#ZOFFL, Z_OFFSETVAL) SPI.write(SPI#ZOFFH, Z_OFFSETVAL >> 8) 'loaded := cognew(read8bitdata(@x,@y), @stack) main Pub Main Repeat Read8BitData If x < 2 and x > -2 servopos := 137 servo.getposition(servopos) elseif x < -1 Addtoservoangle elseif x > 1 Subtractfromservoangle Showdata Pub Subtractfromservoangle if x < 88 servopos := 137 - x servo.getposition(servopos) elseif x > 87 servopos := 50 servo.getposition(servopos) Pub Addtoservoangle if ~x > - 88 servopos := 137 + ||x servo.getposition(servopos) elseif x < - 87 servopos := 225 servo.getposition(servopos) PUB Read8BitData | count,xtemp,ytemp count := 1 xtemp := 0 ytemp := 0 repeat until count == 11 count++ xtemp := xtemp + SPI.read(SPI#XOUT8) 'repeat for X-axis ytemp := ytemp + SPI.read(SPI#YOUT8) 'repeat for Y-axis x := xtemp / 10 x := ~x PUB Showdata DEBUG.Position(20,10) debug.str(string("X= ")) DEBUG.clearend debug.dec(x) DEBUG.Position(20,12) DEBUG.clearend debug.str(string("Y= ")) debug.dec(~y) DEBUG.Position(20,14) DEBUG.clearend debug.str(string("servopos= ")) debug.dec(servopos)▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

CON _xinfreq=5_000_000 _clkmode=xtal1+pll16x 'The system clock is set at 80MHz (this is recommended for optimal resolution) VAR long position 'The assembly program will read this variable from the main RAM to determine the ' servo signal's high pulse duration long Stack 'Alot some stack space for the cog running MoveMotor to use PUB Init cognew(MoveMotor(1),@Stack) 'Start a new cog and run the MoveMotor method on it that outputs pulses on Pin 7 pub tester 'The new cog that is started above continuously reads the "position" variable as it's changed by the example Spin code below repeat position:=50 'Start sending 1ms servo signal high pulses (100 * 10us = 1ms) waitcnt(clkfreq+cnt) 'Wait for 1 second (1ms high pulses continue to be generated by the other cog) position:=225 'Start sending 1.38ms servo signal high pulses (Center position) waitcnt(clkfreq+cnt) 'Wait for 1 second (1.38ms high pulses continue to be generated by the other cog) PUB getposition(pos) position:=pos return PUB MoveMotor(Pin) 'This method outputs a continuous stream of servo signal pulses on "Pin" dira[noparse][[/noparse]Pin]~~ 'Set the direction of "Pin" to be an output repeat 'Send out a continous train of pulses outa[noparse][[/noparse]Pin]~~ 'Set "Pin" High waitcnt((clkfreq/100_000)*position+cnt) 'Wait for the specifed position (units = 10 microseconds) outa[noparse][[/noparse]Pin]~ 'Set "Pin" Low waitcnt(clkfreq/100+cnt) 'Wait 10ms between pulseswaitcnt((clkfreq/100_000)*(position#>10)+cnt)

PUB start(rxpin, txpin, mode, baudrate)

Your missing you pins and mode.

Jim

It's a matter of learning to think logically, paying attention to details, and trying to forget all those things that we all know have to be a certain way. The most difficult part is the last one.