Two new manufacturing tools at Parallax: Torit Cyclone Dust Collector and Samsu

Ken Gracey

Posts: 7,419

Ken Gracey

Posts: 7,419

A while back I posted some photos of some internal improvements we're making to our manufacturing processes. People asked for a few more photos, and some videos. I didn't have any time to make videos, but we hired an intern for the summer who will do this job the way you want it done. Hopefully our sharing of our internal manufacturing helps others create products as well.

The first new machine that arrived is a Donaldson-Torit 20-5 Dust Cyclone for our CNC Router Room (picture below). After some discussion on this forum about dust management we've decided to outsource the plywood robot bases and only build the solar panel kits (acrylic, polycarbonate) inside Parallax. This simplifies the whole dust management issue significantly and it doesn't threaten our electronic assembly (the core of our business, of course). So why the big cyclone? It provides an efficient method of collecting odors and chips from the CNC router and exhausting gases from the Epilog 36EXT Laser Cutter (arrives late June).

This picture shows Scott and David doing some final assembly on the cyclone base before they tilt it up. Scott has experience with cyclones and was really excited to put it together. Next we'll pour a cement pad outside the CNC Router Room and drill an 8" hole through our concrete walls.

An enclosed "baghouse" attaches to the side of the dust cyclone. Four big bags will collect 98% of particles down to 2 microns (?) in diameter. This still didn't excuse us from getting the local air district permit for their unreasonable fee of a thousand bucks. Even though this tool is the best available control technology it still requires a permit in California. Nobody (not even Schwarzenegger) seems to be able to downsize the government and regulations in this state.

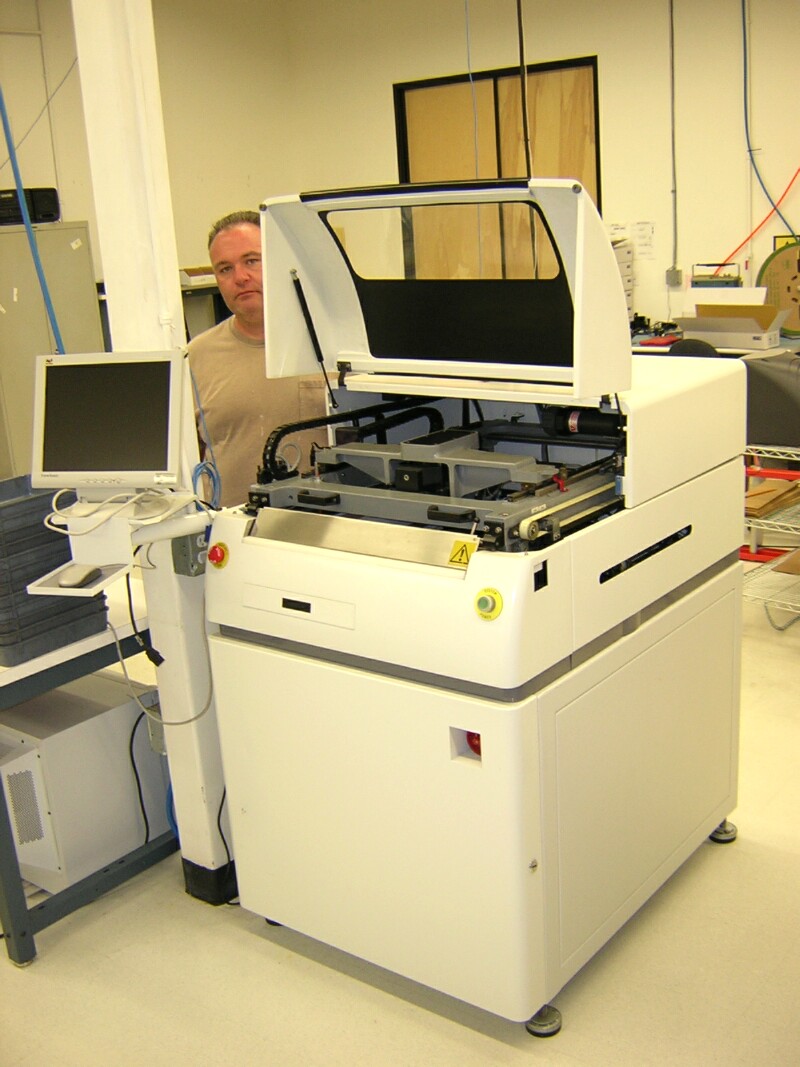

This is a tool that most of you could appreciate - a Samsung 400 Screen Printer. Until this machine arrived we applied solder paste over stencils by hand. This screen printer connects upstream of the Pick & Place. Dennis is excited to see it put to use. Dennis is one of the few people in the office who comes to me with an eBay page and requests "hey, can we order this tool?". He's done a nice job improving our rework tool selection. The manufacturing staff will be trained on the Screen Printer in two weeks.

If you've been to Parallax then you'll recognize the room shown in the picture below as our Training Room. The Training Room has been rebuilt on the other side of the building. This room has been renamed as the "CNC Router Room". Here you'll see our 8020.net polycarbonate enclosure. The Haas SR-100 CNC Router (arrives this week) will live in this big hamster cage. The cyclone dust collector will remove all of the air in the room every two minutes at full speed - we may need to tie the guys to the router with safety gear so they don't get exhausted from the building.

No changes to the CNC milling room except for a basic cleanup. We hired another machinist (Scott) and he promptly rearranged the two milling machines the way he wanted them - facing the operator.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Ken Gracey

Parallax Inc.

Follow me at http://twitter.com/ParallaxKen for some insider news.

Post Edited (Ken Gracey (Parallax)) : 6/3/2010 12:35:00 AM GMT

The first new machine that arrived is a Donaldson-Torit 20-5 Dust Cyclone for our CNC Router Room (picture below). After some discussion on this forum about dust management we've decided to outsource the plywood robot bases and only build the solar panel kits (acrylic, polycarbonate) inside Parallax. This simplifies the whole dust management issue significantly and it doesn't threaten our electronic assembly (the core of our business, of course). So why the big cyclone? It provides an efficient method of collecting odors and chips from the CNC router and exhausting gases from the Epilog 36EXT Laser Cutter (arrives late June).

This picture shows Scott and David doing some final assembly on the cyclone base before they tilt it up. Scott has experience with cyclones and was really excited to put it together. Next we'll pour a cement pad outside the CNC Router Room and drill an 8" hole through our concrete walls.

An enclosed "baghouse" attaches to the side of the dust cyclone. Four big bags will collect 98% of particles down to 2 microns (?) in diameter. This still didn't excuse us from getting the local air district permit for their unreasonable fee of a thousand bucks. Even though this tool is the best available control technology it still requires a permit in California. Nobody (not even Schwarzenegger) seems to be able to downsize the government and regulations in this state.

This is a tool that most of you could appreciate - a Samsung 400 Screen Printer. Until this machine arrived we applied solder paste over stencils by hand. This screen printer connects upstream of the Pick & Place. Dennis is excited to see it put to use. Dennis is one of the few people in the office who comes to me with an eBay page and requests "hey, can we order this tool?". He's done a nice job improving our rework tool selection. The manufacturing staff will be trained on the Screen Printer in two weeks.

If you've been to Parallax then you'll recognize the room shown in the picture below as our Training Room. The Training Room has been rebuilt on the other side of the building. This room has been renamed as the "CNC Router Room". Here you'll see our 8020.net polycarbonate enclosure. The Haas SR-100 CNC Router (arrives this week) will live in this big hamster cage. The cyclone dust collector will remove all of the air in the room every two minutes at full speed - we may need to tie the guys to the router with safety gear so they don't get exhausted from the building.

No changes to the CNC milling room except for a basic cleanup. We hired another machinist (Scott) and he promptly rearranged the two milling machines the way he wanted them - facing the operator.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Ken Gracey

Parallax Inc.

Follow me at http://twitter.com/ParallaxKen for some insider news.

Post Edited (Ken Gracey (Parallax)) : 6/3/2010 12:35:00 AM GMT

Comments

'You going into the T-shirt biz? What will the screen printer get used on? Oh. I missed the photo caption somehow. Never mind.

-Phil

Post Edited (Phil Pilgrim (PhiPi)) : 6/2/2010 10:22:01 PM GMT

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Ken Gracey

Parallax Inc.

Follow me at http://twitter.com/ParallaxKen for some insider news.

Rich H

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

The Simple Servo Tester, a kit from Gadget Gangster.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Ken Gracey

Parallax Inc.

Follow me at http://twitter.com/ParallaxKen for some insider news.