Help with controling 32 servos???

Hi, I'm trying to control the movement and position of 32 servos and need help on how to go about doing it, hardware ect. I think I will use two

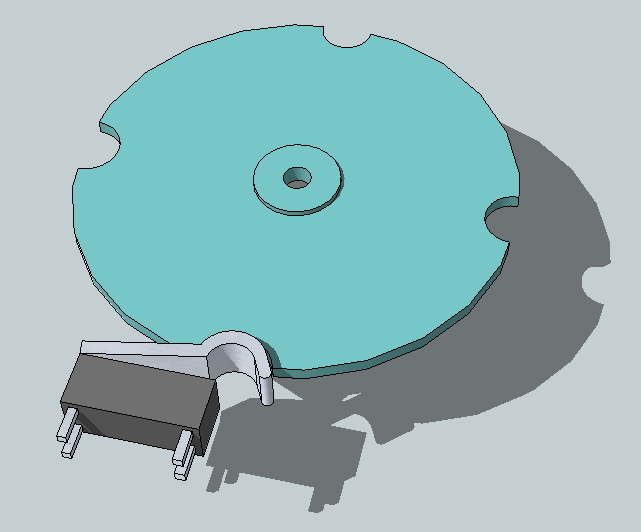

Propeller Servo Controller USB's connected to a basic stamp or a propeller chip to control the servos, but i am not sure on how to individually monitor each servos rotations (continuous) Each servo will have a feedback mechanism like what is in the picture attatched, but how can i count and track all 32 pulses. the servos need to work in unison and not one at a time. Thanks!

Propeller Servo Controller USB's connected to a basic stamp or a propeller chip to control the servos, but i am not sure on how to individually monitor each servos rotations (continuous) Each servo will have a feedback mechanism like what is in the picture attatched, but how can i count and track all 32 pulses. the servos need to work in unison and not one at a time. Thanks!

Comments

-Phil

"or maybe 32 stepper motors would be easier? any way to do that?"

That would be harder to do than the servo.

You don't say how you want to control them? Are you looking for a computer to run a program to move them in a pattern or are you looking for a human to move them?

There is no way it is going to be cheap! What are you looking to spend? What is your time frame?

Al

·

Unless you need to reel out/in the string a long ways I think you would be better off without encoders.

This servo could move your string 16" and you wouldn't need anything to monitor its position; $40 x 32 = $ 1,280!

A cheaper solution would be to use standard servos with long arms. A six inch arm would move the string almost ten inches. $9 x 32 = $288

Neither of these would need to be monitored. The Propeller Servo Controllers will continuously update the servos - moving and keeping them at the proper position.

Rich H

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

The Simple Servo Tester, a kit from Gadget Gangster.

Post Edited (W9GFO) : 5/19/2010 8:16:17 AM GMT

To control 32-36 servos, you can chain two of their 18-servo units together ($40 each)http://www.pololu.com/catalog/product/1354

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·"If you build it, they will come."

Potentially you could use just plain old DC moters with a "whinch drum), with a bead or split shot attached to the string. This bead(s) could trip a small switch. You could also use magnets and a hall effect sensor. If you only need two positions (up and down), you could also set the motors up to stall out at each end of travel. This is what "slow motion" model railroad swtich machines (e.g. tortise and others) do.

While this still will take a fair number of pins, you don't have to deal with pulse widths, etc.

If the balls don't have to move very far, you might also be able to use solenoids.

More detailed info might help with other ideas. My experience is that if you get "locked in" to an idea of how to do something too soon, you end up with a sub optimum solution.

For things that are on public display, simple is almost always better. Less to go wrong, and if it does, easier to fix.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

John R.

Click here to see my Nomad Build Log