Adjustable Current Sensing

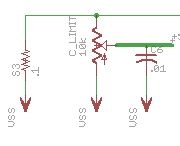

Can someone suggest a better way to do this? I want to use a multi turn pot to adjust the trip point to the +sense input of a 3phase motor driver. The input trips at 100mv volts. In the photo, there is a .1 sense resistor off the low side of the mosfets to the motor. The wiper off the 10k trim pot goes to the driver IC +sense input. My hope was the the voltage would just divide using the pot, and I could set a threshold manually. The way it works out though is that there is no real adjustment, the trim pot is more of an on or off switch, you turn the screw and it finds a thin sweet spot where it toggles the input. What I need is a way to really adjust the voltage level and find the place that makes sense for the application where it should trip. Any suggestions for solving this?

Post Edited (Todd Chapman) : 3/26/2010 6:17:15 PM GMT

Post Edited (Todd Chapman) : 3/26/2010 6:17:15 PM GMT

Comments

Also, I assume there are a set of mosfets in a 3 phase bridge arrangement, switched with some sort of PWM scheme. Can you show a schematic of the drive?

Many commercial units actually measure DC current going into the inverter section so that there is a steadier flow of current compared to measuring one of the phases.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Tom Sisk

http://www.siskconsult.com

·

Post Edited (Todd Chapman) : 4/9/2010 3:43:50 PM GMT

.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

nametag holder