Senior project please help

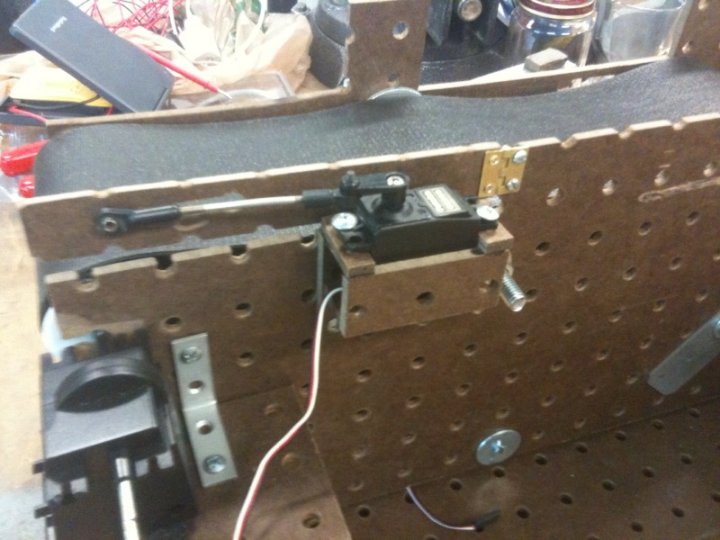

So here is the backround, I have a senior project due in a week and a half and I have been messing around with the Parallax BOE. I am constructing an autonomous waste sorter that must sort glass/plastic/tin-steel/ and aluminum. For sorting the tin-steel(soup can) we have a servo with a magnet attached to an arm that is sweeping under a conveyor belt continuously. For the aluminum we have a proximity inductive sensor wired to the bread board and to a servo arm, such that when the sensor is active the servo door swings open. I need both functions to work at once, aka, the sweeper servo for the tin-steel and the aluminum + sensor setup. Currently I have them both setup, the only problem is that when the sensor actives the door for the aluminum open BUT the sweeper servo stops. I know the problem I am just not very good at programming and PBASIC is still kinda new to me. Any help would be awesome. Below is the current code I am using with pictures.

' {$STAMP BS2}

' {$PBASIC 2.5}

'

[noparse][[/noparse] I/O Definitions ]

PIR PIN 0 'I/O Pin for PIR Sensor

LAR PIN 0

'

[noparse][[/noparse] Variables ]

Setup:

MinVal VAR Word

MaxVal VAR Word

x VAR Word

y VAR Word

z VAR Word

CheckForSensor VAR Word

counter VAR Word

Highest VAR Word

Lowest VAR Word

Lowest=205

Highest=1500

MinVal=205

MaxVal=1600

z=10

'

[noparse][[/noparse] Main Program ]

MAIN:

'Servo Sweeper, just moves from one position back and forth, looping

DO

FOR x=0 TO MaxVal STEP 20

PULSOUT 12, x

PAUSE 5

NEXT

FOR x=MaxVal TO 0 STEP -20

PULSOUT 12, x

PAUSE 5

NEXT

LOOP

Sensor:

DEBUG "Checking for Sensor!" 'checking for sensor

DO

PULSOUT 13, 1100 'returns sensor door to original position

IF PIR = 0 THEN DEBUG "Not Found" 'If sensor isnt sensing anything then servo sweep

'if sensor senses something then open servo door

IF PIR =1 THEN Open

GOSUB Sweep

LOOP

Sweep:

DO

FOR x=0 TO MaxVal STEP 20

PULSOUT 12, x

PAUSE 5

NEXT

FOR x=MaxVal TO 0 STEP -20

PULSOUT 12, x

PAUSE 5

NEXT

RETURN

LOOP

Open:

FOR counter = 1 TO 100

PULSOUT 13, 850

PAUSE 20

NEXT

GOSUB Close

Close:

FOR counter = 1 TO 100

PULSOUT 13, 1100

NEXT

GOSUB Sensor

' {$STAMP BS2}

' {$PBASIC 2.5}

'

[noparse][[/noparse] I/O Definitions ]

PIR PIN 0 'I/O Pin for PIR Sensor

LAR PIN 0

'

[noparse][[/noparse] Variables ]

Setup:

MinVal VAR Word

MaxVal VAR Word

x VAR Word

y VAR Word

z VAR Word

CheckForSensor VAR Word

counter VAR Word

Highest VAR Word

Lowest VAR Word

Lowest=205

Highest=1500

MinVal=205

MaxVal=1600

z=10

'

[noparse][[/noparse] Main Program ]

MAIN:

'Servo Sweeper, just moves from one position back and forth, looping

DO

FOR x=0 TO MaxVal STEP 20

PULSOUT 12, x

PAUSE 5

NEXT

FOR x=MaxVal TO 0 STEP -20

PULSOUT 12, x

PAUSE 5

NEXT

LOOP

Sensor:

DEBUG "Checking for Sensor!" 'checking for sensor

DO

PULSOUT 13, 1100 'returns sensor door to original position

IF PIR = 0 THEN DEBUG "Not Found" 'If sensor isnt sensing anything then servo sweep

'if sensor senses something then open servo door

IF PIR =1 THEN Open

GOSUB Sweep

LOOP

Sweep:

DO

FOR x=0 TO MaxVal STEP 20

PULSOUT 12, x

PAUSE 5

NEXT

FOR x=MaxVal TO 0 STEP -20

PULSOUT 12, x

PAUSE 5

NEXT

RETURN

LOOP

Open:

FOR counter = 1 TO 100

PULSOUT 13, 850

PAUSE 20

NEXT

GOSUB Close

Close:

FOR counter = 1 TO 100

PULSOUT 13, 1100

NEXT

GOSUB Sensor

Comments

Use two stamp boards?

I don't think you have to use a Servo to sweep the magnet under the conveyor belt to look for steel cans. You could have a continously moving DC motor and just have it oscillate when you turn power on. Otherwise I think you could use the ServoPal to control the servos while your Basic Stamp is doing other things.

Here's the data on the ServoPal http://www.parallax.com/Portals/0/Downloads/docs/prod//robo/ServoPAL_doc.pdf

By the way, your several "sweep" routines use a pause of 5ms. The servos are actually made to respond to a pause more like 20ms. You can't really move them faster or smoother by shortening the pause time.

You're going to have problems with your program. You're using GOSUB like a GOTO and there is no corresponding RETURN statement. The GOSUB and RETURN have to be matched up. Use a GOTO if that's really what you mean.

Your min and max values for servo pulses should be around 500 and 1000, certainly not zero and 1,600!

You would also need to trim your Senors subroutine down to the absolute minimum, the DEBUG statements will take a lot of time to execute and will cause the servos to be herky-jerky.

Rich H

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

The Simple Servo Tester, a kit from Gadget Gangster.

Post Edited (W9GFO) : 3/15/2010 6:58:45 PM GMT

opening con 0 closing con 1 sweeper var bit sweepPos var word sweepMin con 205 sweepMax con 1600 gatePos var word gateMin con 205 gateMax con 1500 loopCnt var nibble sweepPos = sweepMin sweeper = opening gatePos = gateMin loopCnt = 0 do pulsout 12,sweepPos if sweeper = opening if sweepPos + 20 > sweepMax sweeper = closing else sweepPos = sweepPos + 20 endif else if sweepPos - 20 < sweepMin sweeper = opening else sweepPos = sweepPos - 20 endif endif pulsout 13,gatePos if loopCnt > 0 loopCnt = loopCnt - 1 endif ' here your program may check various sensors and make some kinds of decisions about what to do next cycle through the loop pause 12 ' shorten this delay depending on how much time the above statement take to execute. The typical execution time ' of the loop should take around 20ms, perhaps a little less. loopThis loop continuously sweeps the servo on pin 12. It also will maintain the position of the servo on pin 13. To open the gate, set gatePos to gateMax. To close the gate, set gatePos to gateMin. It will take a few cycles of the loop for the gate servo to move to the requested position. This can be handled by setting loopCnt to 15 when gatePos is set, then not reacting until loopCnt becomes zero.

Note change in sweepMax / sweepMin testing.

Post Edited (Mike Green) : 3/15/2010 11:36:37 PM GMT

'IF loopCnt > 0 THEN

'loopCnt = loopCnt - 1

'ENDIF

'IF PIR = 1 THEN

'gatePos=gateMax

' FOR counter = 1 TO 50

'gatePos=gaetMin

'ELSE

' gatePos=gateMin

'ENDIF

This code works for the aluminum door, the sweeper servo I am still having trouble with though, the sweeper servo will only stay at the end of the servo range in either direction, I have tried changing the values but am not quite sure what is wrong. The servo sweeper stays at max range then sweeps once and returns to max range and stays there.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

- Stephen

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

- Stephen

MaxVal VAR Word

x VAR Word

opening CON 0

closing CON 1

sweeper VAR Bit

sweepPos VAR Word

sweepMin CON 500

sweepMax CON 1600

gatePos VAR Word

gateMin CON 1100

gateMax CON 800

loopCnt VAR Nib

sweepPos = sweepMin

sweeper = opening

loopCnt = 0

MaxVal = 1600

counter VAR Word

DO

PULSOUT 12,sweepPos

IF sweeper = opening THEN

IF sweepPos + 20 > sweepMax THEN

sweeper = closing

ELSE

sweepPos = sweepPos + 20

ENDIF

ELSE

IF sweepPos - 20 < sweepMin THEN

sweeper = opening

ELSE

sweepPos = sweepPos - 20

ENDIF

ENDIF

PULSOUT 13,gatePos 'Aluminum door servo arm

IF loopCnt > 0 THEN

loopCnt = loopCnt - 1

ENDIF

IF PIR = 1 THEN

gatePos=gateMax

ELSE

gatePos=gateMin

ENDIF

Alright the sweeper is working and the aluminum door arm works but only like once or twice and then stops after the ferrous metal is introduced.

PULSOUT 13,gatePos 'Aluminum door servo arm

IF loopCnt > 0 THEN

loopCnt = loopCnt - 1

ENDIF

IF PIR = 1 THEN

gatePos=gateMax

ELSE

gatePos=gateMin

ENDIF

When introduced with the sweeper arm code its really up in the air if the sensor will activate or not. Sometimes when the sensor is placed right next to the material it will work, but sometimes the sensor just does not read it at all. Something to do with the sensor loop not activating? Individually each code block works perfectly, but when introduced with each other all heck breaks loose and the sensor gets a mind of its own. The base code that I am playing around with is the same as what is posted directly above. Thank You!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

- Stephen

Post Edited (UNFMech) : 3/16/2010 11:15:27 PM GMT

Click on the post reply button and use the attachment manager to attach your code.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

- Stephen

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

- Stephen

' {$STAMP BS2} ' {$PBASIC 2.5} PIR PIN 0 sweep_servo PIN 12 door_servo PIN 13 forward VAR BIT opening VAR BYTE sweep_value VAR WORD door_value VAR WORD min_value CON 400 max_value CON 1100 open CON 850 closed CON 1100 '********************************* sweep_value = min_value door_value = closed opening = 0 DO PULSOUT sweep_servo, sweep_value PULSOUT door_servo, door_value IF PIR = 1 THEN door_value = open opening = 1 ENDIF IF opening > 0 THEN opening = opening + 1 IF opening >= 50 THEN opening = 0 door_value = closed ENDIF ENDIF IF sweep_value => max_value THEN forward = 0 IF sweep_value =< min_value THEN forward = 1 IF forward = 1 THEN sweep_value = sweep_value + 20 ELSE sweep_value = sweep_value - 20 ENDIF PAUSE 15 LOOP '***********************************Rich H

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

The Simple Servo Tester, a kit from Gadget Gangster.

Post Edited (W9GFO) : 3/18/2010 6:03:57 AM GMT

The PAUSE 15 is there to try to keep your loop running at 50 times a second. If the sweep servo is too slow the way to speed it up is to increase the amount that the sweep_value changes each time through the loop.

Put this at the top along with the other declarations:

Then replace -

With this;

Now when you want to alter the speed of the sweep servo just change the number assigned to sweep_change at the top of the program.

Put the PAUSE 15 back and only reduce it if the servo is stuttering.

Rich H

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

The Simple Servo Tester, a kit from Gadget Gangster.

Post Edited (W9GFO) : 3/19/2010 5:40:25 PM GMT

You could also create another CON for that value (just like we did for sweep_change above) so that you can adjust it from the top of your program rather than having to dig down through the code to find the value. Not really an issue in this short program but it is a good habit to get into.

Rich H

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

The Simple Servo Tester, a kit from Gadget Gangster.