multi KiloAmp Speed controller based on a BS2

Aloha one and all .. I have a weard project on my hands from the Auto Tech teacher

He needs me to make a Speed con for a what apperers to be a starter motor

.. yes i know there one of the worst motors to use for a GOkart . but its whats handed to me .

BTW the motor is not tyed to Ground inside!!

this is a huge plus !

that aside I am still "attempting " to make it work .

STATS :

the no load peak starting A is 250 or so . @ 12 Vdc ( optima YellowTop 750 CA batt)

DC Ω is 4.3 .

.

My guess is I will be up to 1800Amps Peak stall full load .

I am using IRLB3036 Fets

PDF attached...

My main issue I see is the leads on the TO-220 package are small I might fuse them open .

Mind the Peak rating on these Fets are 1100 amps

so I am doing some tricks to keep them as short as possible to the main Bus ( 1/4' Cu Rod)

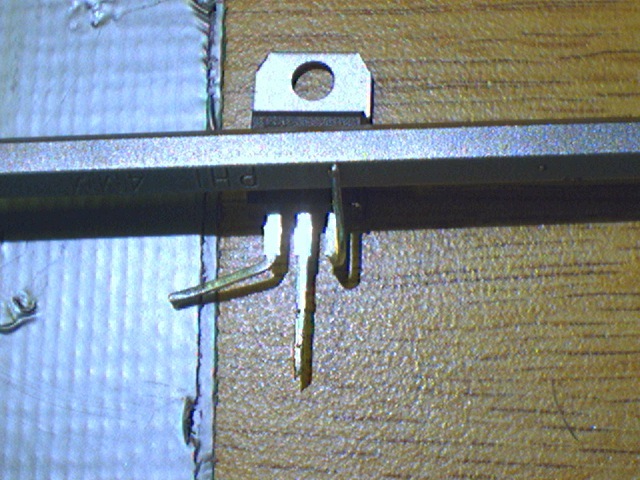

Attached is a sample photo of how I plan to bus them

note how the sorce lead is bent over to a large bus rail ( there is NO way Cu Clag can handle 500+amps .)

Note I am not using the rod ( but a part of a screwdriver) . but you will get the idea .

also I am using a milled Cu strip on the tab for the drain connection ( not photo yet ) .

The Fets are rated at well over 100Amps a chip so I figured 10 of them should work .

MOSFETs parallel Well Unlike BJTs so this should not be a issue on the high current side.

the input side is going to to be a small issue but I think I know a way to switch them super fast .

On the stamp side is where I had the most fun . I learned how do math to scale teh pot RC time or 0-6XX to the 0- 65K for pulsout in the stamp and how to use VARs and how to pulsout.

as long as I can drive the Fets hard on and off I see no huge issue .

that's why I chose logic fets ... and in 1K quanty ther $1.somthing a chip . not bad !!!

the last speed con ai made was 350A cont @ 120V rated ran at 48V .

it used a LM556 .

I wanted to use a stamp for its abatily to be smater then ye old 556 . and with a BS2 I can do some SW hacks to limit the speed with a encoder or also limit from Hi Amps and what not .

granted a Prop would be Ideal but I dont know Spin nor have the time ..

/...

My backup plan is to gut a large power inverter for its Fet drivers and its Fets and case .

Figure the large ones draw up to 500A so it may work .

EDIT my code is on the computer in the E Tech Lab . no accesss till monday . POO.

but I will post it with a sample running video to show Scope output .

EDIT!! the code is up !!!!

Peter KG6LSE

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Carpe Ducktum" "seize the tape!!"

peterthethinker.com/tesla/Venom/Venom.html

Never underestimate the bandwidth of a station wagon full of tapes hurtling down the highway. —Tanenbaum, Andrew S.

LOL

Post Edited (Peter KG6LSE) : 3/8/2010 5:53:52 PM GMT

He needs me to make a Speed con for a what apperers to be a starter motor

.. yes i know there one of the worst motors to use for a GOkart . but its whats handed to me .

BTW the motor is not tyed to Ground inside!!

this is a huge plus !

that aside I am still "attempting " to make it work .

STATS :

the no load peak starting A is 250 or so . @ 12 Vdc ( optima YellowTop 750 CA batt)

DC Ω is 4.3 .

.

My guess is I will be up to 1800Amps Peak stall full load .

I am using IRLB3036 Fets

PDF attached...

My main issue I see is the leads on the TO-220 package are small I might fuse them open .

Mind the Peak rating on these Fets are 1100 amps

so I am doing some tricks to keep them as short as possible to the main Bus ( 1/4' Cu Rod)

Attached is a sample photo of how I plan to bus them

note how the sorce lead is bent over to a large bus rail ( there is NO way Cu Clag can handle 500+amps .)

Note I am not using the rod ( but a part of a screwdriver) . but you will get the idea .

also I am using a milled Cu strip on the tab for the drain connection ( not photo yet ) .

The Fets are rated at well over 100Amps a chip so I figured 10 of them should work .

MOSFETs parallel Well Unlike BJTs so this should not be a issue on the high current side.

the input side is going to to be a small issue but I think I know a way to switch them super fast .

On the stamp side is where I had the most fun . I learned how do math to scale teh pot RC time or 0-6XX to the 0- 65K for pulsout in the stamp and how to use VARs and how to pulsout.

as long as I can drive the Fets hard on and off I see no huge issue .

that's why I chose logic fets ... and in 1K quanty ther $1.somthing a chip . not bad !!!

the last speed con ai made was 350A cont @ 120V rated ran at 48V .

it used a LM556 .

I wanted to use a stamp for its abatily to be smater then ye old 556 . and with a BS2 I can do some SW hacks to limit the speed with a encoder or also limit from Hi Amps and what not .

granted a Prop would be Ideal but I dont know Spin nor have the time ..

/...

My backup plan is to gut a large power inverter for its Fet drivers and its Fets and case .

Figure the large ones draw up to 500A so it may work .

EDIT my code is on the computer in the E Tech Lab . no accesss till monday . POO.

but I will post it with a sample running video to show Scope output .

EDIT!! the code is up !!!!

Peter KG6LSE

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Carpe Ducktum" "seize the tape!!"

peterthethinker.com/tesla/Venom/Venom.html

Never underestimate the bandwidth of a station wagon full of tapes hurtling down the highway. —Tanenbaum, Andrew S.

LOL

Post Edited (Peter KG6LSE) : 3/8/2010 5:53:52 PM GMT

pdf

285K

Comments

Rich H

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

The Simple Servo Tester, a kit from Gadget Gangster.

Be careful when milling or drilling copper: it is notorious for 'grabbing' the bit, so both copper and the tooling

need to be tightly clamped and nothing held in the hand.

Regards,

T o n y

W9GFO . series wound motors are the most popular motors for DC based EVs..

I did a small(er) scale test in lab last week when I started this project .

I used a small Shopvac and a 120V DC PSU I used some 400V 15A Fets with great success.

Vacs use a series wound motor to.

as for over Rev this is one of the reason I used a stamp. I am putting a Tach pulse and a comparator so that if the this thing ever over revs it will cut back .

( figure more 5V pluses in to a Cap teh more analog voltage . and once it goes over a point set by a comparator the thing will trip A input on the BS2 to GOSUB STOP .

Also its mounted in a GO cart and as long as the wheels done come off the ground it has a very lile chance of over rev .

Thanks guys for the pointers

KG6LSE

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Carpe Ducktum" "seize the tape!!"

peterthethinker.com/tesla/Venom/Venom.html

Never underestimate the bandwidth of a station wagon full of tapes hurtling down the highway. —Tanenbaum, Andrew S.

LOL

I was fascinated at how irregular the no load speed was, varying by plus and minus 10%...

Remember that starter motors have to be intrinsically safe because mechanics with very littler skill will handle them. The guy I bought my one from used a hammer when another motor wouldn't start. He was a bit miffed when I didn't want to take that one!!!

You probably know about the OSMC project (open source motor control) and the controller they developed. It's got a great reputation.

www.robotpower.com/products/osmc_info.html

Also google it

Kind regards from Kwa Dukuza - somewhere in darkest Africa

John Bond

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Your setup is a bit more advanced than that was, but I do not think the peak currents will be as high as you expect and will be of short duration.

To get good acceleration and a reasonable top speed you will need a gear ratio around 7 or 8 to one. A high frequency PWM will limit the starting current somewhat due to the motor winding inductance, and as the RPM increases the counter EMF will do the limiting.

... its going to be much higher when we force 24V trugh it ..

its a huge motor for what it is ..

sadly the compuers were locked out so the code will have to wate till the morning ...

the only issue I have ran in to is the pulsout command maxes out at 95% or so duty cycle . but this should not be a huge issue

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Carpe Ducktum" "seize the tape!!"

peterthethinker.com/tesla/Venom/Venom.html

Never underestimate the bandwidth of a station wagon full of tapes hurtling down the highway. —Tanenbaum, Andrew S.

LOL

If my math serves me right

24v X 1600A ( my initial figure) = 38 KW and just for now lets assume 100% Eff thats 51 HP !!

That's a boat load of raw power .

the whole EV will be under 600Lbs .

this thing is going to Move !!!!

I too used a stater back when I was a kid ..I used a UPS hand truck and made a dragster . [noparse]:)[/noparse]

It had so much touqe I had to put a cement bag on the front to keep it from flipping.

PS . the code is up-loaded on the first post .

Peter KG6LSE

(back to lab class)

EDIT I found some 130A Fets in lab .. I may do a small scale test with teh large motor

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Carpe Ducktum" "seize the tape!!"

peterthethinker.com/tesla/Venom/Venom.html

Never underestimate the bandwidth of a station wagon full of tapes hurtling down the highway. —Tanenbaum, Andrew S.

LOL

Post Edited (Peter KG6LSE) : 3/8/2010 6:11:32 PM GMT

I did it with NO load .

and ramped up the speed very slowly.

I did not pop a FET . Good !

I also proved that my buss rail system will work very well !

the only part I have not made is a driver system for the FETs

this is next ( this week )

I am just pleased My Code worked as planned..

Peter KG6LSE

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Carpe Ducktum" "seize the tape!!"

peterthethinker.com/tesla/Venom/Venom.html

Never underestimate the bandwidth of a station wagon full of tapes hurtling down the highway. —Tanenbaum, Andrew S.

LOL

The major problem I can see is the motor overheating. Are you planning to monitor the motor temperature?

Besides overheating issues, I suspect the motor may have a fairly short life in this application: brushes, commutator, and bushings will wear quickly in continuous use, especially pushing the weight of an adult around.

I don't want to be a killjoy, just go easy on it and enjoy it as long as it lasts! Be sure to befriend the Pep Boys (auto parts store) clerk and maybe he'll warranty replace your motor a few times during your development process. Don't tell him you're using it in a go-kart. For reasons that baffle the mind, ya just "can't keep a starter motor" in Aunt Edna's old Chevy Caprice Classic.

PS: I'd avoid using a speed controller out of a Toyota... [noparse]:)[/noparse]

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·"If you build it, they will come."

My old dragster worked great for years until I smoked it at 32V . ( ahh the "moar Powar " instincts of our youth)

It too had a nasty tendency to nearly flip from Epic Wheeles and that was at stock 12V.

If it was ME making this beast it would be a AC induction motor with a IGBT Drive at 300V

Erco: its funny the motor on the inside was modded with ball bearings .

The machine tech guys rebuilt the whole thing from what I see .

I am also doing Over current monitoring too and its goint to tweak a varable in my code to de-rate the speed Con to prevent over draw .

Mind none of this is in my current Beta test code .

The FETs are ordered and on there way !

Peter KG6LSE

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Carpe Ducktum" "seize the tape!!"

peterthethinker.com/tesla/Venom/Venom.html

Never underestimate the bandwidth of a station wagon full of tapes hurtling down the highway. —Tanenbaum, Andrew S.

LOL

But it lasted 30Min!!!!

the PDF says 100A+ .. I guess this is on Die or something cause at 80 A the FEts drains Fused open .

So for now we are using a big contactor and that's it !

So far this is what I have for the front panel ...

L to R : Hi Low switch , ARM ing and Estop , (Easy) GO button ...

The Speed Con is not over yet !! .. I have a ton more FETS to pop LOLs ..

I am making a better system to route power to the FETs .... But for now On off is the only option as its needed done on the 10th of july !

Peter KG6LSE

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Carpe Ducktum" "seize the tape!!"

peterthethinker.com/tesla/Venom/Venom.html

Never underestimate the bandwidth of a station wagon full of tapes hurtling down the highway. —Tanenbaum, Andrew S.

LOL

Post Edited (Peter KG6LSE) : 6/30/2010 12:24:54 AM GMT

Here is a First light of the kart with the reversed motor !!!!! with Just a contactor ..

www.flickr.com/photos/peterthethinker/4771998401/

got Amps?!

We are makeing a new motor mount ! cause the one we have is twisting like crazy ..

Peter KG6LSE

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"Carpe Ducktum" "seize the tape!!"

peterthethinker.com/tesla/Venom/Venom.html

Never underestimate the bandwidth of a station wagon full of tapes hurtling down the highway. —Tanenbaum, Andrew S.

LOL