Simple Art Project

I have an interest in creating a robotic drawing machine, inspired from several of the posts I've seen here.

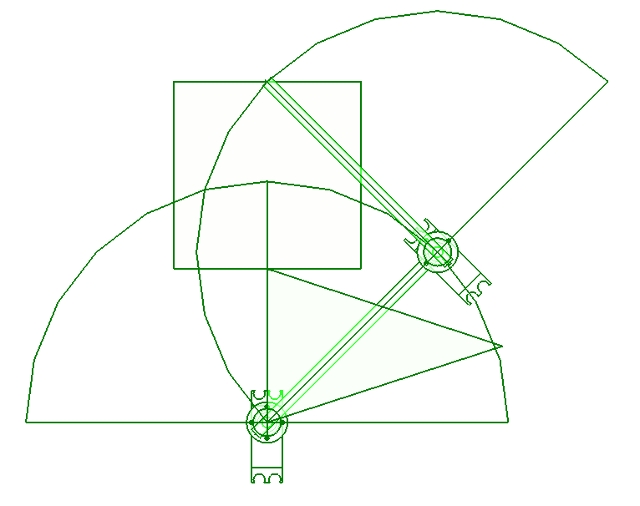

Although the sketch seems to show an obvious imbalance with the servo atachments, I have a few ideas to solve this.

Here's something I jotted down - I first want to construct a prototype, work out many of the bugs, then move on to a more revised, substantially larger robot.

I'm off for the next four days & I'd really like to have the first prototype "quasi functional" by the time I have to return to the classroom.

Thanks for any comments or suggestions - and encouragement [noparse];)[/noparse],

And yes, the other projects I'm working on are still "in progress" . . .

Scope

[noparse]:)[/noparse]

Although the sketch seems to show an obvious imbalance with the servo atachments, I have a few ideas to solve this.

Here's something I jotted down - I first want to construct a prototype, work out many of the bugs, then move on to a more revised, substantially larger robot.

I'm off for the next four days & I'd really like to have the first prototype "quasi functional" by the time I have to return to the classroom.

Thanks for any comments or suggestions - and encouragement [noparse];)[/noparse],

And yes, the other projects I'm working on are still "in progress" . . .

Scope

[noparse]:)[/noparse]

Comments

Dream big or go home?

Why not at least start with a Scribbler? It's ready to draw; designed to hold a sharpie, and goes straight enough for short distances. Get 'em while you still can from secondary sources, P'lax is out.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·"If you build it, they will come."

As far as writing the code for this - I haven't put much thought into it - I've determined that for me, thinking can be dangerous.

Besides - why rob myself of a challenge? I think it can be done - I'm not looking for perfection, just something to satisfy my curiosity.

Happy roboting,

Scope

Are you doing math on the fly, or plotting a few data points and interpolating? I know there are a few undocumented trig functions in the Stamp that you could use.

The Peaucellier is one of my favorite old mechanical linkages. All it does is make a straight line. I used to make my students build one of those. Cute animation at ·http://www.math.toronto.edu/~drorbn/People/Eldar/thesis/Transformer.htm

erco

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·"If you build it, they will come."

Are you creating a homebrew Scribbler robot? I have

developed a robot arm that can print and write using

CNC language for labeling tags. I think your idea can

be developed into something similar, as you mentioned,

for writing initials, etc. You could use a cantilevered stylus

and a wide XY for printing the most characters in one

general area.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

humanoido

*Stamp SEED Supercomputer *Basic Stamp Supercomputer *TriCore Stamp Supercomputer

*Minuscule Stamp Supercomputer *Three Dimensional Computer *Penguin with 12 Brains

*Penguin Tech *StampOne News! *Penguin Robot Society

*Handbook of BASIC Stamp Supercomputing

*Ultimate List Propeller Languages

*MC Prop Computer

Mostly math on the fly (see the image below) . . . it looks like I've started creating a custom font . . . I guess I could call it Scopia? I wasn't "horrible" with math in college, but I haven't done much serious math lately so, mathematics is one of my robotic Achilles heels.

Sort of - it's being developed as I go - who knows what's around the corner.

Post Edited (Scope) : 2/15/2010 12:48:35 AM GMT

I only have two "large" motors w/2 motor controllers but that's an easy fix.

I plan on making a very small, working prototype of this machine using the continuous rotation servos from my Boe-Bot - but I only have two of those also. [noparse]:([/noparse]

As always - comments &/or suggestions are most appreciated.

I found a web page that allows me to print some nice gears. I thought I'd cut them out of foam - for a prototype only, of course. I have made several foam cutters which I have used to make r/c airplanes but I couldn't find one, so, I made this one very quickly.

I am unsure if this will work but I plan on making two rack & pinion systems and test them out using continuous rotation servos.

Oh well . . . here goes.

I'm trying to be optimistic but I may have to just bite the bullet and grab some pre-fab gears & stuff

Aside from that, I like your scribbler idea. At first I thought it'd never work, but After the video........ I think I'd better keep that to myself.

Have fun! and keep posting pics!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"puff"...... Smile, there went another one.

OK - and thanks for the encouragement!

I'd really like to make a 4' x 8' x 2" thick foam cutter out of this thing - or - maybe have a different 3rd axis: one for artwork & signs, one for cutting foam . . . hmmm . . .

Post Edited (Scope) : 2/17/2010 12:53:36 AM GMT

coating that would harden to form a more durable gear for your project? Like a foam core surfboard!

·

Electrostatically coat the foam parts with graphite and you could metal plate them like is done with plastic parts for consumer products.

Duffer

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Any technology, sufficiently developed, is indistinguishable from magic.· A.C. Clark(RIP)

For prototype #2, I'm considering using ~1/4" thick plastic kitchen cutting board for the rack & pinion items. Perhaps I shouldn't mention this, I don't wanna create "eek overload" but, I have a complete CNC shop (mill, lathe, & router) at work but I can't use the stuff - I'm just barely learning how to use the CNC router. Because of this, and my familiarity with foam, this robotic endeavor is extremely primitive & crude. But fun, nonetheless.

This reminds me of building an r/c plane from scratch - it's always exciting and satisfying when it flies well.

Thanks! [noparse]:)[/noparse]

Post Edited (Scope) : 2/17/2010 3:55:09 AM GMT

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

- Stephen

Yes, but I will have to create a better hot wire machine. The one I tossed together this afternoon was just to get me by and was designed for using only "thin" foam insulation - this cutter uses 3.0 VDC (2 batteries in a flashlight enclosure - see photo above), chop sticks, and 0.010 Ernie Ball Regular Slinky guitar string for the cutting wire. Hey, it works.

I also figured out I'll need to use linear sets of bar codes on each rack (?) to correct pinion placement when the motors get out of sync. I calibrated them again before this test but blah, blah, blah.

Also, I realize the rack & pinion mesh is low quality - I will resolve some of this as the project continues.

Post Edited (Scope) : 2/17/2010 5:12:19 AM GMT

Could anyone suggest a better means of synchronizing the motors? I thought of using a photo resistor to calculate a very accurate distance - bounced off a wall on the end of each rack. Does this seem feasible?

And . . . I discovered the "squishyness" of the foam adds a measure of value to the overall lousy craftsmanship.

Aren't newbies frustrating? (sorry)

Thanks

I began Prototype 02 today using a single rack & pinion, centered on the trolley. I'm also using larger pieces for two reasons:

1 - to "minimize" the irregularities in precision parts

2 - to allow me to use standard rotation servos while still being able to achieve a usable range of trolley motion

3 - to eliminate the alignment problem discovered with prototype 01

This prototype will provide up to ~235 mm of movement given a 180% range. Theoretically, I should be able to provide a quasi-suitable range of accuracy with this resolution - again, just to test a slightly further developed concept.

Oh well . . . we'll see how it goes.

That's MUCH better!!!

Sure, the video shows the movement is "rough" for sure, but the trolley only has one small guide and no bearings - I haven't even smoothed out the pinion & rack mesh yet.

Very frustrating . . . back to square one. Prototype 02 didn't turn out so great after all.

If I only knew what I was doing, this would be fun.

I think.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·"If you build it, they will come."

No, erco, I didn't know that but I really do appreciate the help. When it comes to mechanical stuff, electronic stuff, and programming, I'm really a klutz, so, I guess it's fitting I have taken an avid interest in robotics, eh? (ha)

I will probably create a 3rd rack & pinion with the suggestions you offered but first, I want to make a "slider" mechanism, similar to the image I posted earlier that looks like a crankshaft & piston assembly. I've already done some math with this system and it seems "doable," albeit confusing to control "accuracy" when creating the drawings and foam cutting I want to produce. I think I calculated the range of motion to be 150 degrees which translates into 10 inches of linear travel. And ya, I realize there's not a linear relationship between the angle of rotation and linear distance output (is that the right way to say it?).

Thanks

Check out these links they may help you in your project development.

flying-pig.co.uk/mechanisms/

technologystudent.com/cams/camdex.htm

They were included in the geared candle holder project in Make magazine. It was a project hand cutting gears out of aluminum to make a candle holder. Here is a link to the article

www.make-digital.com/make/vol21/?pg=92

Hope this gives you some help in your design process.

Al