Pneumatic can crusher controlled by a BS2 on a Homework Board

Hello All!· This is my first attempt at sharing one of my creations with the community, so here goes...

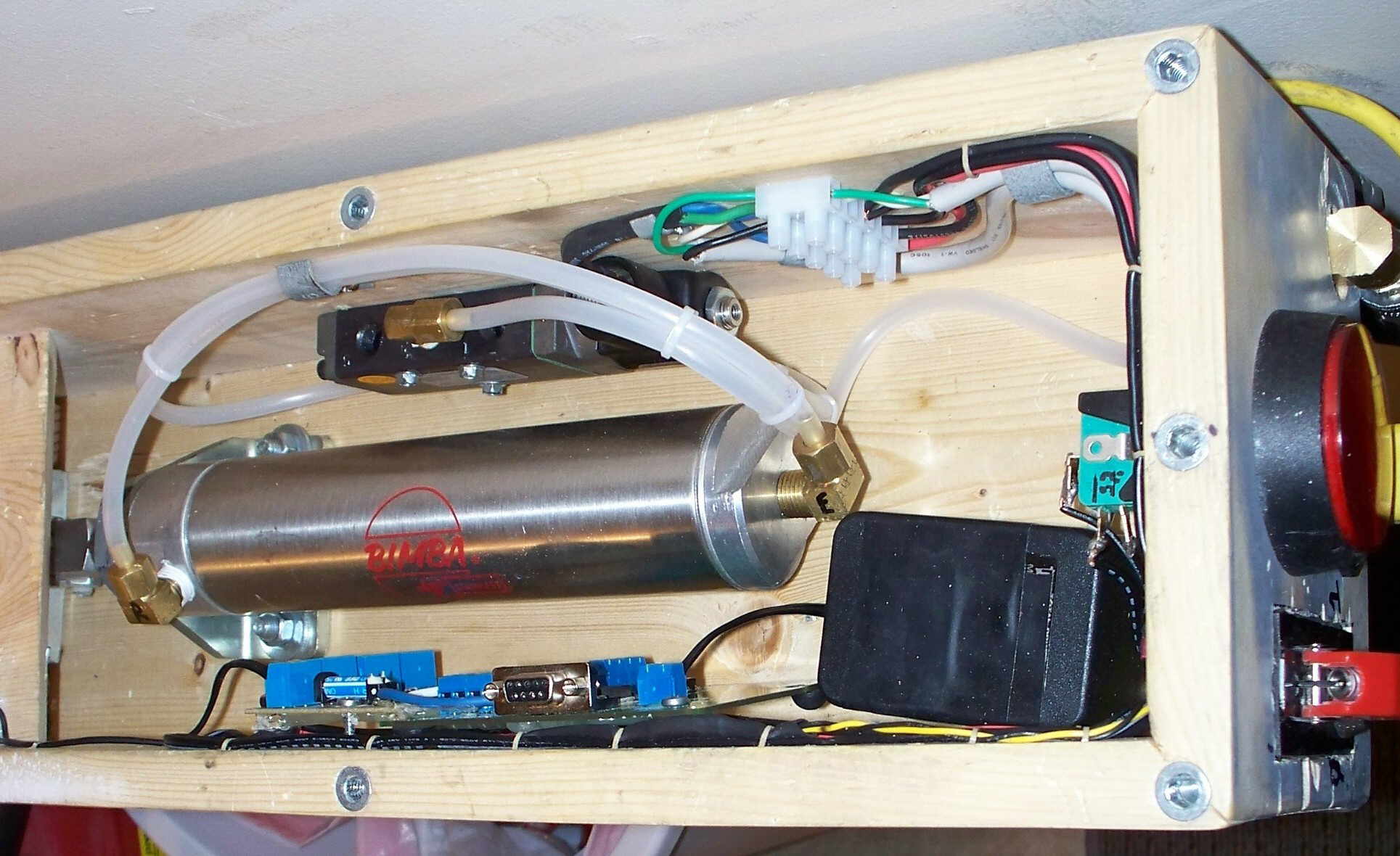

This is the "Cannihilator", a pnuematic powered can crusher that is controlled by a BS2 on a modified Homework Board.· My two sons, Jake-8, Ryan-5 and I built it together when the boys decided that they wanted to be more environmentally responsible and start recycling.· We started with a simple wall mounted hand crusher, but I knew we could do better than that! (Insert Tim Allen grunt here...arrghh, arrggh, arrggh!!!)

I wanted something more permanent, so I removed the included breadboard and used the screw terminals for the connections to the Homework Board and then layed out and etched a simple board·on which·the relay, pull-up and protection resistors and switch inputs were placed.· This was my first attempt at creating my own board, including etching and it took a little trial and error to get it right, but I finally did.· I wound up having a friend use a jpeg of the circuit to cut an etch mask using a vinyl cutting plotter typically used to make lettering for vehicles and windows.· It worked flawlessly! I'll include pictures of the board with the mask applied, before it was etched.

The control circuitry includes three switches that provide input to the stamp and one switch that controls the AC power to the solenoid valve.· The toggle switch with the red cover is used to cut the AC to the solenoid valve while still allowing the low voltage components to remain powered up.· The "Big Red Button" is what actuates the valve to extend and retract the piston and the key switch is used to completely disable the unit.· In one of the pictures with the lid open, you'll see the third switch.· It's a magnetic reed switch that acts as a safety to prevent·the piston·from being extended and/or retract·it if the lid is opened while extended.

It's fully functional now, but we have future plans for an autoloader system and fresh paint job with obligatory flames, decals·and chomey-go-fast parts!!

Thanks for looking and please feel free to comment.

UPDATED - YouTube video link.

http://www.youtube.com/watch?v=PcXpM-dxjLQ

Post Edited (Jeff Walsh) : 2/13/2010 2:06:57 AM GMT

This is the "Cannihilator", a pnuematic powered can crusher that is controlled by a BS2 on a modified Homework Board.· My two sons, Jake-8, Ryan-5 and I built it together when the boys decided that they wanted to be more environmentally responsible and start recycling.· We started with a simple wall mounted hand crusher, but I knew we could do better than that! (Insert Tim Allen grunt here...arrghh, arrggh, arrggh!!!)

I wanted something more permanent, so I removed the included breadboard and used the screw terminals for the connections to the Homework Board and then layed out and etched a simple board·on which·the relay, pull-up and protection resistors and switch inputs were placed.· This was my first attempt at creating my own board, including etching and it took a little trial and error to get it right, but I finally did.· I wound up having a friend use a jpeg of the circuit to cut an etch mask using a vinyl cutting plotter typically used to make lettering for vehicles and windows.· It worked flawlessly! I'll include pictures of the board with the mask applied, before it was etched.

The control circuitry includes three switches that provide input to the stamp and one switch that controls the AC power to the solenoid valve.· The toggle switch with the red cover is used to cut the AC to the solenoid valve while still allowing the low voltage components to remain powered up.· The "Big Red Button" is what actuates the valve to extend and retract the piston and the key switch is used to completely disable the unit.· In one of the pictures with the lid open, you'll see the third switch.· It's a magnetic reed switch that acts as a safety to prevent·the piston·from being extended and/or retract·it if the lid is opened while extended.

It's fully functional now, but we have future plans for an autoloader system and fresh paint job with obligatory flames, decals·and chomey-go-fast parts!!

Thanks for looking and please feel free to comment.

UPDATED - YouTube video link.

http://www.youtube.com/watch?v=PcXpM-dxjLQ

Post Edited (Jeff Walsh) : 2/13/2010 2:06:57 AM GMT

Comments

Post Edited (Jeff Walsh) : 2/12/2010 6:35:36 AM GMT

Your code is nice and clean as well, good job. It would be nice to see a video of it in action. Do you have the Bimba cylinder toned down for an easy crush or left wide open for a ramming crush? Do you plan to add some type of display for the can count?

Welcome to the community, keep the projects coming!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Andrew Williams

WBA Consulting

WBA-TH1M Sensirion SHT11 Module

Special Olympics Polar Bear Plunge, Mar 20, 2010

Propeller-Based Reverse Geo-Cache Birthday Present Project

Thanks!· The cylinder isn't dialed down at all, but the tubing I used does slow it down a little compared to the larger 3/8" hose used to feed it from the compressor.· It still works VERY well down to about 50 PSI and the small Porter Cable compressor I have it hooked to shuts off at about 135 PSI.· It'll crush about 4 cans before the compressor kicks in to refill the tank, but even with the compressor turned off we can still crush over 20 cans before the pressure drops too low to be effective.· I actually have added a mechanical counter to display the can count, but I would like to convert it to and LCD or maybe just some 7 segment displays.· I also have a pressure transducer that I plan on adding to the mix at some point for the purpose of controlling the compressor directly from the stamp and may at some point fabricate a nicer control panel, although if I'm not careful, this could easily become "Dad's project" rather than something for the boys and I to do together...

Thanks again for the kind words and encouragement!

-Jeff

To put that in perspective, if I were to crush 1 can per second, nonstop, it would take over 3 years to fill up the register.

Nicely done,

DJ

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Chris Savage

Parallax Engineering

·

1- What size pneumatic cylinder did you use?

2- What did you make the ram out of?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Shawn Lowe

When all else fails.....procrastinate!

I'll try to get a clear picture of it and post it up.

I don't mind answering questions at all!· In fact, I'm blown away by the response the "Cannihilator" has gotten!· Thank you all very much.

Post Edited (Jeff Walsh) : 2/12/2010 9:32:38 PM GMT

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Shawn Lowe

When all else fails.....procrastinate!

I feel your eBay withdrawal pains! I can't get there from work either. Mine came from eBay, I think it was about $30-$40 including shipping. I got a REALLY good deal on the solenoid valve. I bought a lot of 6 for less than $20 including shipping! I still have some left, so let me know if you end up needing one and I'll be glad to sell you one cheap.

Ya, Ok. Let me get home and check out Ebay. I appreciate the offer on the solenoid valve, I'll let you know!

Thanks

P.S. Love the video

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Shawn Lowe

When all else fails.....procrastinate!

Thanks to a recommendation by Mikerocontroller, we made Hack a Day!!!!

http://hackaday.com/2010/02/18/cannihilator-can-crusher

Great device. My wife just told me I need to do sometinglike this with my grandkids: Girl 9, Boy 6. Would love to see them have an interest in these types of projects instead of gaming all the time!!! Thanks if you can help.

The cylinder is powered by a small Porter-Cable pancake compressor.·A·pressurized tank/cannister would work until the pressure dropped below the effective range, which for·ours, that's about 50-60 PSI.· I'll be glad to help in any way I can and·good luck in getting grandkids involved!

Post Edited (NWCCTV) : 3/2/2010 7:05:56 AM GMT

Anyway, to answer your question, I've seen some at Harbour Freight Tools, Sears and eBay.

I'm always tinkering with the crusher, so please let me know what your plans look like once you get them going.

DocThomas: He has a safety switch already:

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Andrew Williams

WBA Consulting

WBA-TH1M Sensirion SHT11 Module

Special Olympics Polar Bear Plunge, Mar 20, 2010

My first thought is brought about from having 3 boys ages 18, 15, and 13 in the house. How do you keep them from crushing a full can??? I'm sure my boys would just love to see a coke explode from being crushed!!!

Second, and probably more useful. What do you think about hydrolics. I imagine they are more expensive than the pneumatics, but it might be offset by not needing the pancake air compressor.