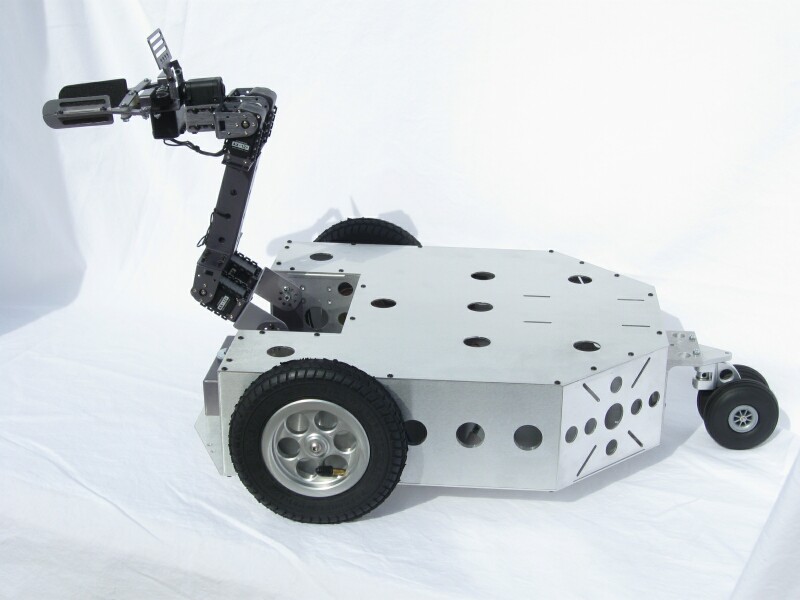

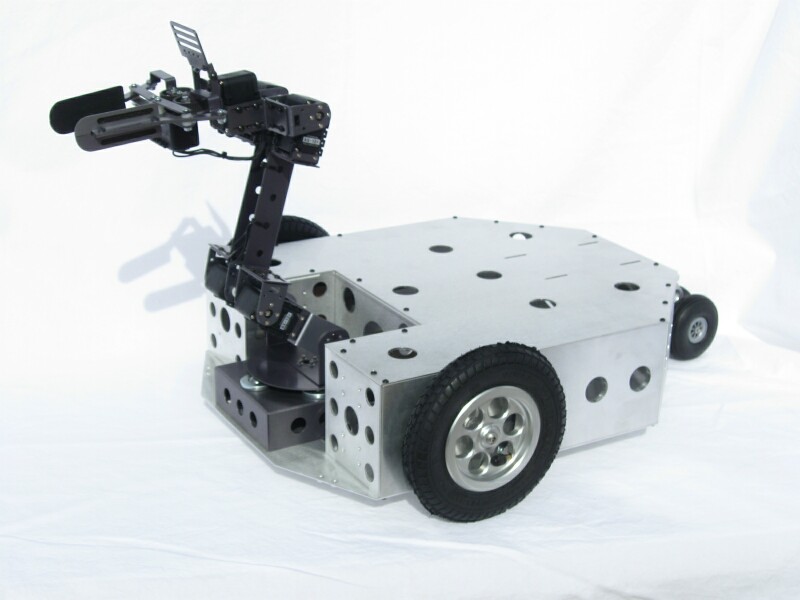

Crustcrawler Nomad - robot kit built around the 12V Motor Mount Wheel Kit

Ken Gracey

Posts: 7,419

Ken Gracey

Posts: 7,419

Hey all,

My friend Alex at Crustcrawler has developed a new prototype of the Nomad robot, which uses their robotic arm. The kit uses the Parallax 12V Motor Mount and Wheel Kit (27971) and the Caster Wheel (28971). These photos are a prototype, without anodization. Alex kindly provided approval for us to share the prototype photos on these forums.

I don't know the sale price or availability details. I imagine it will be between $500 and $800 without the arm, however.

Well done, Crustcrawler!

Ken Gracey

My friend Alex at Crustcrawler has developed a new prototype of the Nomad robot, which uses their robotic arm. The kit uses the Parallax 12V Motor Mount and Wheel Kit (27971) and the Caster Wheel (28971). These photos are a prototype, without anodization. Alex kindly provided approval for us to share the prototype photos on these forums.

I don't know the sale price or availability details. I imagine it will be between $500 and $800 without the arm, however.

Well done, Crustcrawler!

Ken Gracey

Comments

Naturally, Poor Cousin is doubly up to the task. Pic attached!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·"If you build it, they will come."

Post Edited (erco) : 1/31/2010 5:39:53 AM GMT

So, are those two arms going to pick up the micro-ercos and put them on the bot?

Ken Gracey

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·"If you build it, they will come."

-Phil

I'm reminded of the drama of the very first Viking Mars lander way back in 1976. I was a teenager, eagerly following the mission through (UGH!) daily newspaper updates, and I remember it quite clearly. After landing, the soil sampler arm wasn't operating properly, one joint was frozen. NASA was in a quiet state of panic for 5 days, as most of the experiments depended on the sampling arm. It took 5 days for anyone to go back and "read the manual"·to determine that a locking pin (which protected the arm in transit) was designed to fall out from gravity only with the arm joints in a very specific positions. Overly-enthusiastic controllers had forgotten that juicy little fact. Once they did as the instructions said, the pin fell free and the robot arm worked perfectly. Plain-vanilla details at· http://www.solarviews.com/history/SP-425/ch13.htm

Always read the manual!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

·"If you build it, they will come."

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

"A complex design is the sign of an inferior designer."