PropNET Module = Propeller Web Server beta / software development tester

Timothy D. Swieter

Posts: 1,613

Timothy D. Swieter

Posts: 1,613

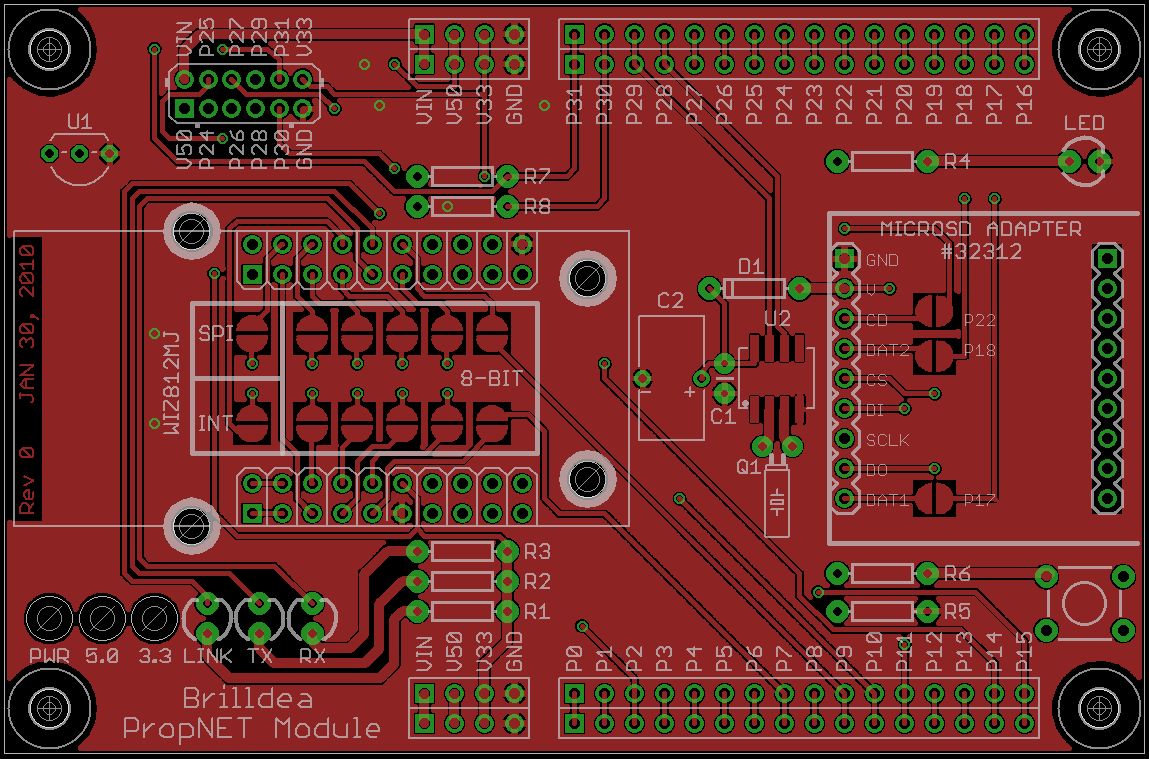

OK gang, the discussion over in the Propeller Web Server thread has me geeked. I like the WizNET chip and I think it pairs well with the Propeller. I have wanted to design a system like what Parallax is doing because of some various projects and learning I wanted to do so I am inspired to see their product work. Once I saw Parallax working on a design I figured I would wait for them to finish. However as the discussion developed I realized there is an opportunity right now to quickly put some parts together to start working on software. At first I was thinking of attaching modules to the Propeller ProtoBoard, but that was a little messy. So I thought I would do a simple plug 'n work PCB. So therefore that is what I did and I chose to use the Propeller Platform as the basis of the design:

PropNET Module - a W5100 based Propeller Platform Module (for the Propeller Platform sold at Gadget Gangster)

Included in the design:

For the most part I followed the schematic published by Parallax. There are a couple oddities though, for instance the WizNET module doesn't bring out the W5100 /SCS and SEN signals. Instead there is glue logic on the WizNET module and only a SPI ENABLE signal is brought out on the headers. I attached the SPI ENABLE signal where the SEN normally goes on the Propeller. I also left off the 3-pin 'serial' interface header.

The solder jumper pads I think are a bonus in this design. When one setups of the PropNET you can decide if you want to use the W5100 in SPI or 8-bit mode/Indirect. Obviously the 8-bit mode takes more pins and with the Propeller Platform stackable I didn't want to connect pins to the modules that aren't going to be used if you wanted SPI mode. There is flexibility then in expanding to other modules without the risk of burning the W5100 up. Most pins are already connected for SPI module. The solder jumpers should take a drop of solder to ensure the pads are bridged. The pads are those half circle shape devices between the WizNET module headers. Some pins are shared between SPI and 8-bit mode so those are always connected such as /RESET and a couple others.

The design is a two layer PCB. The schematic and PCB are being worked on in EAGLE. I plan to order plenty of PCBs. I hadn't thought through if I or someone else will offer kits. Again, since the majority of the items are headers/resistors and through-hole most people may have the items sitting around. And of course, you can populate only those items you need so if you are interested in the WizNET module and don't care about the RTC or SD card, then you can leave those items unpopulated.

What do you think? I am hoping to order the PCB early next week.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

PropNET Module - a W5100 based Propeller Platform Module (for the Propeller Platform sold at Gadget Gangster)

Included in the design:

- A longboard module that plugs on top of Propeller Platform.

- A footprint for plugging in the WizNET WIZ812WJ module. This module has a W5100 IC on it. The module can be bought from various dealers on-line.

- A footprint for plugging in the Parallax MicroSD-Card Adapter.

- A footprint for the Maxim DS2502-E48 IC, which shares the /INT line to the WizNET module. This IC is a user option to include a MAC ID - or just store data on the SD card or in the EEPROM.

- A footprint for the MoBo header.

- Footprints for the proposed RTC S-35390A IC and super capacitor

- LEDs for Link, Tx, and Rx indicators from the WizNET module.

- User interface LED and switch.

- Solder jumper pads for configuring the WizNET module to use only SPI interface or to use the 8-bit and SPI interface. If only using the SPI interface the other I/O can remain free for stacking another module on top of the PropNET module.

- The majority of the design is through-hole components and modules, so just about anyone can assemble the module for prototyping. The RTC IC is the only surface mount components and is an SOP-8 package.

For the most part I followed the schematic published by Parallax. There are a couple oddities though, for instance the WizNET module doesn't bring out the W5100 /SCS and SEN signals. Instead there is glue logic on the WizNET module and only a SPI ENABLE signal is brought out on the headers. I attached the SPI ENABLE signal where the SEN normally goes on the Propeller. I also left off the 3-pin 'serial' interface header.

The solder jumper pads I think are a bonus in this design. When one setups of the PropNET you can decide if you want to use the W5100 in SPI or 8-bit mode/Indirect. Obviously the 8-bit mode takes more pins and with the Propeller Platform stackable I didn't want to connect pins to the modules that aren't going to be used if you wanted SPI mode. There is flexibility then in expanding to other modules without the risk of burning the W5100 up. Most pins are already connected for SPI module. The solder jumpers should take a drop of solder to ensure the pads are bridged. The pads are those half circle shape devices between the WizNET module headers. Some pins are shared between SPI and 8-bit mode so those are always connected such as /RESET and a couple others.

The design is a two layer PCB. The schematic and PCB are being worked on in EAGLE. I plan to order plenty of PCBs. I hadn't thought through if I or someone else will offer kits. Again, since the majority of the items are headers/resistors and through-hole most people may have the items sitting around. And of course, you can populate only those items you need so if you are interested in the WizNET module and don't care about the RTC or SD card, then you can leave those items unpopulated.

What do you think? I am hoping to order the PCB early next week.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

Comments

And like you said - it allows for an early start for the software.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

www.mikronauts.com E-mail: mikronauts _at_ gmail _dot_ com 5.0" VGA LCD in stock!

Morpheus dual Prop SBC w/ 512KB kit $119.95, Mem+2MB memory/IO kit $89.95, both kits $189.95 SerPlug $9.95

Propteus and Proteus for Propeller prototyping 6.250MHz custom Crystals run Propellers at 100MHz

Las - Large model assembler Largos - upcoming nano operating system

The module is a quickly thrown together design. I truely intend to use it as a development for the Parallax product. Perhaps with time and feedback this module can evolve.

You can review the info on the WIZ812MJ here: [noparse][[/noparse]urlhttp://www.wiznet.co.kr/en/pro02.php?&ss=2&page=1&num=91

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

Always have to ask, but I think the Wiznet is $20(?) by itself, what do you think the retail price will be for this as a kit, with the Wiznet?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Propeller Forums RSS Feed!

Gadget Gangster - Share your Electronic Projects

The kit could be offered ala cart. For instance, the kit could have the RTC IC, but another add-on option could be the MAC ID IC. The user can also get the microSD module as they wish or the WIZnet module as they wish. I was thinking an entire kit for everything on the PCB would be nice, but may be that would discourage sales too.

For the moment I do know this - I ordered PCBs and I will be giving them away some of them for others to get going on software. I will also be selling them too. The PCBs ship to me on February 6th so I should get them early next week. This is good because the following week is Chinese New Year and I hope to have some time then to code and try out the PCB.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

One last tip....take your time on a design. Work on it. Put it aside. Come back to it later and review it with clean eyes. Print it out. Lay parts on it. Turn the design different colors on the monitor, rotate. Basically take time to review the design to make it the best it can. Don't worry if it comes out with problems or looking awkward, iteration is an important part of design - though not always affordable in time or money.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

Tomorrow I should confirmation of the PCBs shipping, and then it is only matter of time for delivery and assembly and verifying.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

I will pick up the parts from the office Thursday or Friday. I post pictures once I get the items. The goal over the holiday weekend (besides writing some software for work) is to populate and verify circuits and connections on the PCB. Then I can announce plans for distributing the PCBs.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

Attached are a couple of photos of the PCB and of some of the components placed on the PCB. In the next couple days I should be able to solder up a test unit and prove the PCB design is OK. Off the bat I can see that I could have improved a couple component placements like the uSD card module. I also see that the holes for the WIZnet module to the PCB are slightly off (really small, but off), but that is OK for my app since I wasn't planning to use them.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

Random question - what's the current consumption of the Wiznet? I wonder how long it will run on batteries.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Propeller Forums RSS Feed!

Gadget Gangster - Share your Electronic Projects

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

www.mikronauts.com E-mail: mikronauts _at_ gmail _dot_ com 5.0" VGA LCD in stock!

Morpheus dual Prop SBC w/ 512KB kit $119.95, Mem+2MB memory/IO kit $89.95, both kits $189.95 SerPlug $9.95

Propteus and Proteus for Propeller prototyping 6.250MHz custom Crystals run Propellers at 100MHz

Las - Large model assembler Largos - upcoming nano operating system

Jim

I spent my Saturday morning soldering together a PropNET. You can see the pictures of the assembly attached. Don't worry about those blue wires, there is nothing wrong with the PCB. Digi-key would not let me buy the RTC IC that was chosen for the design, the same one as shown on the Parallax schematic (Seiko S-35390A) and therefore I bought a different IC and had to map the pins to the footprint. The assembly of the board was fairly easy because of the through hole design. You can also see in the pictures how well the solder jumper bridges work. I have my first unit to run on either SPI or indirect address to the W5100. I also have the SD card detect wired in as well as the one-wire bus to an unused Prop pin.

I got a small list of nice to haves should I ever do a design revision, but at the moment this design is looking solid from the assembly and board documentation view point. Next step is to power it up and see how it works!!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

Done:

Left to do:

Stay tuned....

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

JMH

Done:

To do:

As a community we should coordinate the effort for writing the software. I think we need to right two solid, generic (configurable) routines for the W5100. One is an SPI routine and one is an Indirect routine. The routines should be similar enough such that the application code doesn't have to change the routine names for reading and writing data. That is to say that an application code could work with either the SPI or the Indirect interface based on which driver is initialized and few, if any, other changes to the code. We should parse out the tasks to different individuals who want to pitch in for coordinating this effort.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

The only thing I can forewarn you about is this: if one commits to a task, make sure it is carried out. This entails a means of task scheduling and management.

This group seems mature enough to entrust each member to finish a job, and we can have a lot of fun doing it. But, if it becomes a drag and a nag, we can run into "issues"

Count me in, especially if the job is sufficiently described (SPECIFICATIONS!). I've written specs all my professional life, and I am sure the majority here has, too.

Maybe some sample projects, specs and simple management forms are in order.

I know, this can suck all the fun out of it (you're FIRED Huselton!). So keep it simple, light-hearted and fun.

Just sayin'

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

JMH

A while back myself and others started work on the SPI code. We decided that while the hydra driver worked it wasn't fast enough (written in spin). We were able to speed things up so we could read/write to the W5100 at 10mhz (the W5100 couldn't go any faster, see the datasheet). At present I think the only thing left to do is move the Tx/Rx code (maybe more) into the assembly portion and possibly create a circular buffer. This should give the SPI code a boost.

http://forums.parallax.com/showthread.php?p=851153

Post Edited (DynamoBen) : 2/14/2010 7:02:56 PM GMT

I am working with Nick at Gadget Gangster to see about offering a kit. I won't be able to offer a kit because Digi-key is blocking the ability to ship the Seiko RTC IC to Singapore and I haven't found another source locally yet. The minimum you need to get started is a PCB, a WIZ812MJ module and a couple headers/sockets. Then you can attach the PCB to a Propeller Platform or wire it up to another Prop board. The other items such as uSD, RTC IC, etc can be added if you want them.

Yesterday I started cooking up a new SPI driver in ASM. This is based on the previous code I started. So far I am only as far as setting the various addresses. Next step is adding function for opening/closing sockets, etc. One thing I like about the attached driver, if I do say so myself, is that it is easy to follow and well documented. I would appreociate any feedback to make it even better. Stay tuned for added functionality. Another reason for creating this new SPI driver is that I am trying to structure it so that it is easy to pull the "SPI RUG" out from under it and replace it with "Indirect bust mode carpet".

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

Post Edited (Timothy D. Swieter) : 2/16/2010 1:48:53 AM GMT

Ben - thanks for the link to the thread. I need to reread that thread.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

The important bit is that counters are being used to speed up SPI communication I see no reason why this same method couldn't work the same for the indirect mode.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter, E.I.

www.brilldea.com - Prop Blade, LED Painter, RGB LEDs, 3.0" LCD Composite video display, eProto for SunSPOT

www.tdswieter.com

When you look at the code each line is one bit, hence 32 lines of ASM. The speed that this occurs is based on the counters speed.

Post Edited (DynamoBen) : 2/16/2010 2:14:01 AM GMT

that are arranged only by Spin to generate interactive html with with images and sounds.

(One cgi language should be enough.)

I have the Etherx module for Hydra but haven't put it to good use yet.

Just commenting for encouragement. This may be something I would like to build or buy.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

I should be typing in Spin now.

Coming soon. My open Propeller Project Pages and favorite links index.

so i can control my rov over a net work cable,i am useing a sytech joystick· usb· from a lap top and sending all the control down throw a rj45 cable can anybody help me

I would suggest you start a new thread, this will ensure you get the attention you deserve.