Light-duty (and cheap?) pan and tilt: any interest?

Phil Pilgrim (PhiPi)

Posts: 23,514

Phil Pilgrim (PhiPi)

Posts: 23,514

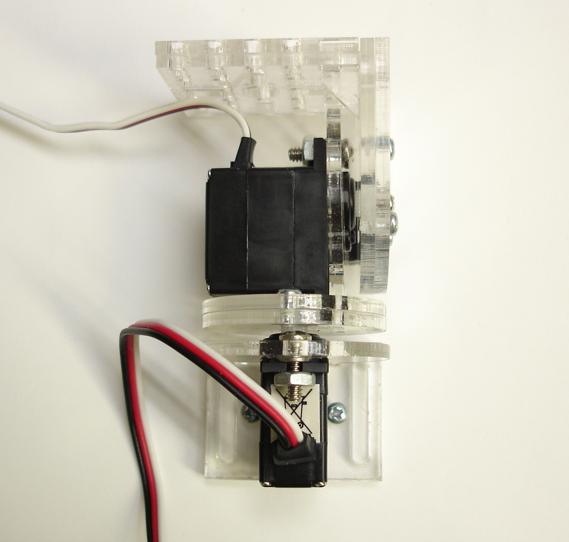

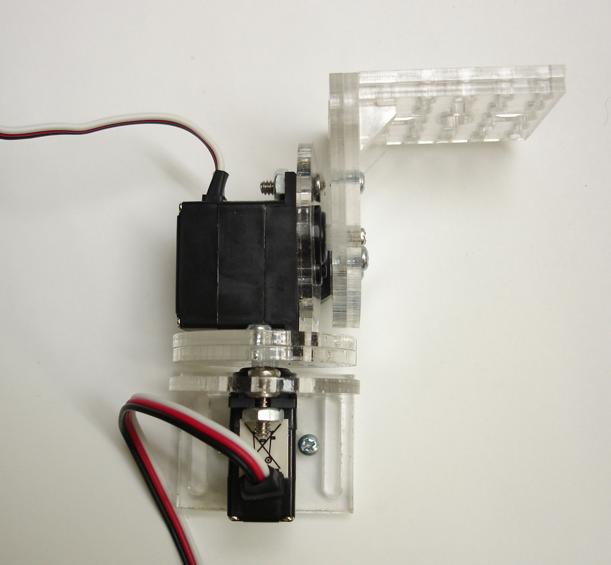

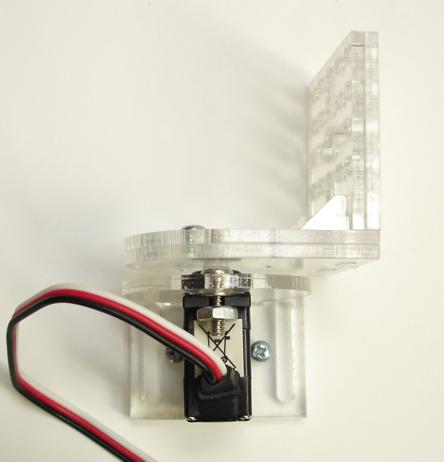

I've come up with a light-duty pan and tilt mechanism that relies on a pair of GWS Naro (Parallax Pico) miniature servos. It's made of laser-cut 0.093" clear acrylic and assembles easily with lock-tabs and screws. It can be configured in two different pan/tilt modes and one pan-only mode. The various configurations are illustrated in the attached photos. The zip file contains a video that shows it in action mounted on a Boe-Bot.

The base is designed to mount to a vertical surface and has two vertical slots for #4 screws an inch apart. The top piece includes a 1/4" center hole and various peripheral holes and slots for #4 screws.

Is there any interest in such a thing? If so, how much would you be willing to pay for a hardware-only kit (excluding the servos) that includes the twelve acrylic pieces and the fasteners required for assembly? 'Loaded question, I know, but an honest answer will tell me whether it's worth pursuing further.

Thanks,

-Phil

_

Post Edited (Phil Pilgrim (PhiPi)) : 1/17/2010 7:21:59 AM GMT

The base is designed to mount to a vertical surface and has two vertical slots for #4 screws an inch apart. The top piece includes a 1/4" center hole and various peripheral holes and slots for #4 screws.

Is there any interest in such a thing? If so, how much would you be willing to pay for a hardware-only kit (excluding the servos) that includes the twelve acrylic pieces and the fasteners required for assembly? 'Loaded question, I know, but an honest answer will tell me whether it's worth pursuing further.

Thanks,

-Phil

_

Post Edited (Phil Pilgrim (PhiPi)) : 1/17/2010 7:21:59 AM GMT

Comments

Those particular servos cost Parallax about $8 each, just so you know. . . penguin actuators.

Would sell reasonably well, but I'm wondering if this is better done in sheetmetal. Such a design idea has floated around our office for quite some time though we never acted on it. But nobody has made the design and here you are with a solution.

We'll take 50 units. Anything that mounts on the Boe-Bot is usually a winner. It's probably the second most popular hobby-education robot (I imagine Mindstorms is first).

Ken Gracey

Parallax Inc.

I can't disagree that sheet metal could be the more appropriate material for this. But, as you know, I've got a new hammer, and I'm looking for nails to pound with it.

Thanks,

-Phil

I've been using these - and at less than $3 each . . . I'm thinking of using a metal Altoids box and making something similar but I don't wanna buy any Altoids . . . yes, I'm incredibly cheap . . .

www.hobbypartz.com/topromisesg9.html

Post Edited (Scope) : 1/17/2010 3:11:21 PM GMT

-Phil

_

Post Edited (Phil Pilgrim (PhiPi)) : 1/18/2010 4:06:40 AM GMT

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

- Stephen