Senior Design Project - Robotic Arm

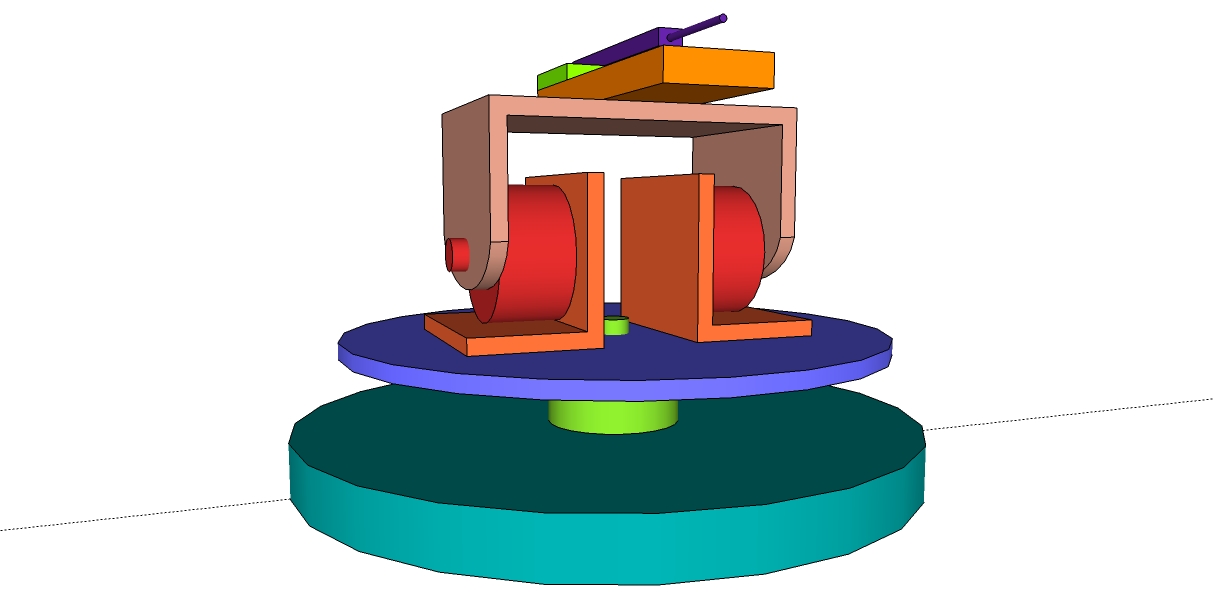

Hi, I'm trying to create a robotic arm for the mechanical part of my senior design project and I'd like to know if these components will achieve what I want. Essentially, I need to position a needle using parameters outputted from MATLAB. I've attached a schematic of my concept. There are are 4 steppers in total. One to rotate the base, two to lift the arm up and down, and the last one acts as a linear stage to move the needle forward.

I am thinking of the following parts:

The stepper motor has a step angle of 7.5 degrees but I would like to half-step it to 3.75 degrees.

I'm also wondering if I can use the stepper motor above to create a linear stage because the commercial linear stages I've seen are very expensive (in the thousands).

Thank you.

I am thinking of the following parts:

- Board of Education (USB) - Full Kit http://www.parallax.com/Store/Microcontrollers/BASICStampProgrammingKits/tabid/136/List/0/SortField/4/ProductID/294/Default.aspx?txtSearch=boe+serial

- 4-Phase / 12 Volt Unipolar Stepper Motor (x4) http://www.parallax.com/StoreSearchResults/tabid/768/List/0/SortField/4/ProductID/65/Default.aspx?txtSearch=unipolar+stepper+motor

- ULN2003 (x4) (driver)

The stepper motor has a step angle of 7.5 degrees but I would like to half-step it to 3.75 degrees.

I'm also wondering if I can use the stepper motor above to create a linear stage because the commercial linear stages I've seen are very expensive (in the thousands).

Thank you.

Comments

You could use a ULN2803 instead of the ULN2003 and get 8 Darlington drivers per package·instead of 7.· This would allow you to use only two driver chips (two motors per chip)·instead of four.

Four motors would use up your 16 I/O pins.· That's ok as long as you don't plan to add anything else.· The control information from the PC would come in through the programming interface which is separate from the I/O pins.

The documentation for the stepper motor gives some information on half-stepping.

Linear stages are expensive because most motion transducers are rotary (like a stepper motor)·and there needs to be a mechanical conversion to linear motion that has very very little slop.· Since you're designing and building your own as part of the project, you avoid the issues of design cost, construction cost, reproducibility, volume manufacturability, reliability, etc.

Post Edited (Mike Green) : 12/9/2009 6:39:01 PM GMT

Post Edited (Allan_G) : 12/9/2009 8:51:44 PM GMT