AD5220 controlling PWM with 555 and BS2

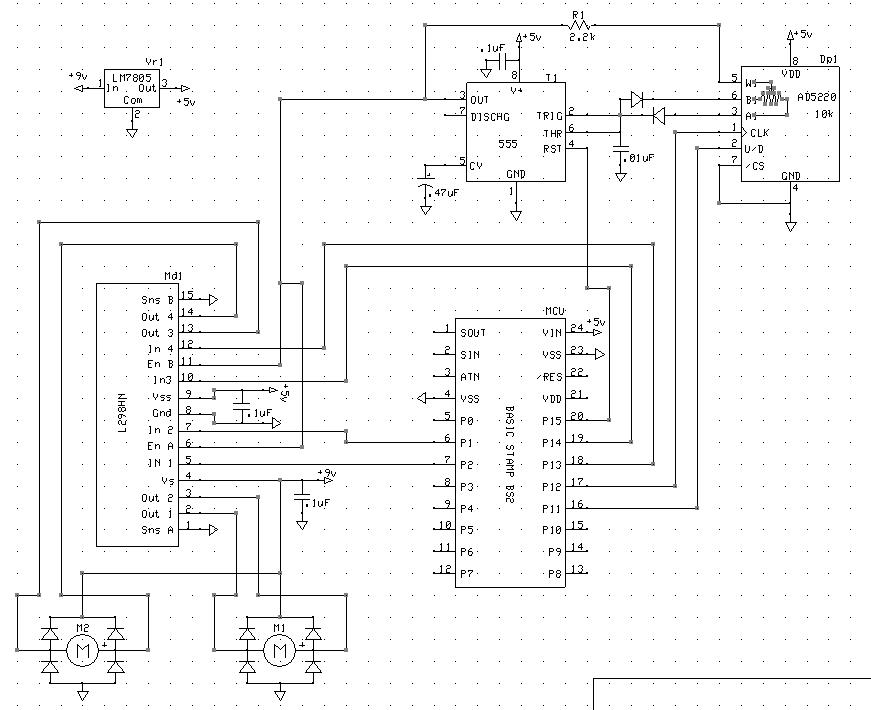

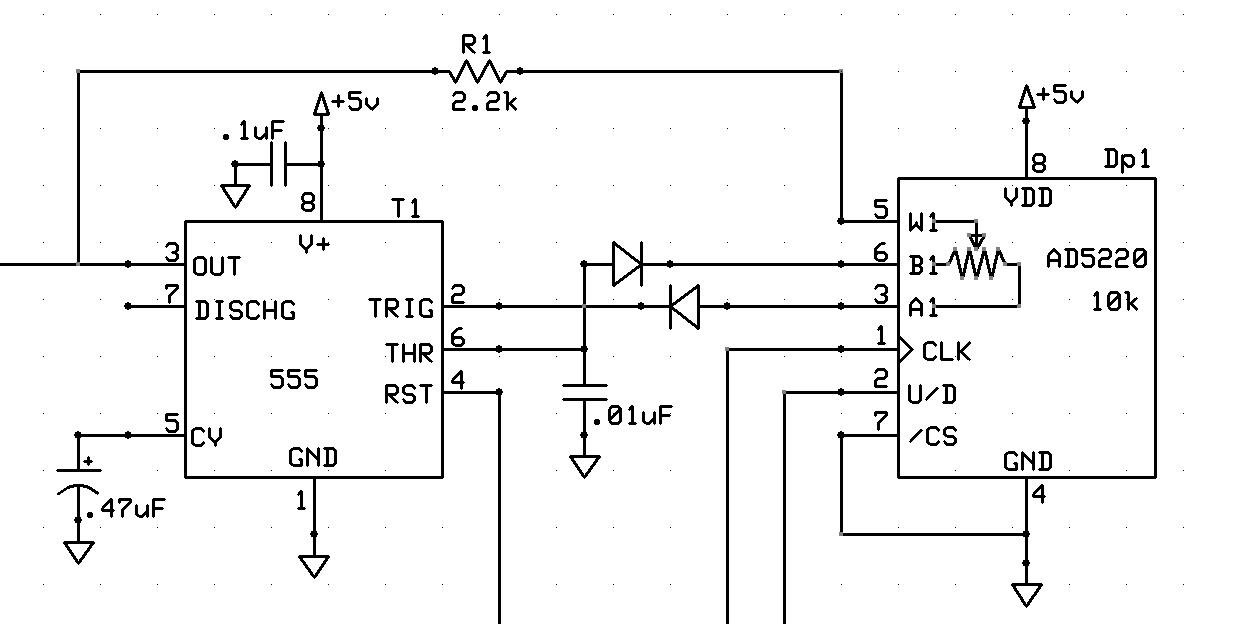

Here is a schematic of My "Tank-Bot" It uses a 555 and AD5220 as a BS2 controlled PWM circuit to send clock pulses to the enable inputs of an L298 dual H-bridge motor driver.

At the beginning of the program I reset the AD5220 to the A position which results in an almost 0% duty cycle. Using this little bit of code.

Then using this code...

This works fine with the motors accelerating smoothly as the resistance of the ad5220 from W1 to B1 decreases and the duty cycle increases.

Then the motors slowing down as the opposite happens.

Problem is when I run the below pre-programmed type code It acts erratically speeding up to full speed at random times or slowing down.

Batteries are fresh and the bug seems to have no real pattern. If I redo the program right after it may show different symptoms or none at all.

I think I may need a large capacitor across the power lines of select chips to prevent the motors turning on at speed 10 from a stop possibly overloading the MCU....idk.

Anyone spot any obvious problems?

Thanks!

Post Edited (Campeck) : 12/6/2009 8:42:36 PM GMT

At the beginning of the program I reset the AD5220 to the A position which results in an almost 0% duty cycle. Using this little bit of code.

HIGH UD 'move wiper toward A side PWM CLK, 255, 127

Then using this code...

' What's a Microcontroller - DigitalPotUpDown.bs2

' Sweep digital pot through values.

' {$STAMP BS2}

' {$PBASIC 2.5}

'-----------------------------------VARIABLES

counter VAR Byte

'-------------------------------DEFINE OUTS DIRS------------------

OUTS = %0000000000000000

DIRS = %1111111000100110

'----------------------------------------RESET AD5220-------------------------

HIGH 11 'move wiper toward A side

PWM 12, 255, 127 'apply 127 position changing clock pulses

'This program resets the AD5220 to the full A side for 0% duty cycle. then goes from tap 0 of the ad5220 and makes its way up to tap 127

moving one tap every 10ms or so. Therefore increasing motor speed. Then it counts down.

'-----------------------INITIALIZE MOTOR DIRECTION---------------------------------------------

OUTS = %1100000000000010 'bit 15 = 555 control, bit 14 = left track forward, bit 1 = right track forward.

'------------------------------ACCELERATE----------------------------

DO

LOW 11 'set wiper to move toward B side of ad5220.

FOR counter = 0 TO 127 'count from 0 to 127

PWM 12, 255, 1 'pulse CLK pin of ad5220 1 time then

PAUSE 10 'then wait 10 ms

NEXT

'------------------------------DECELERATE--------------------------------------

HIGH 11 'set wiper to move toward A side of ad5220

FOR counter = 127 TO 0 ' count down from 127

PWM 12, 255, 1 'pulse CLK pin of ad5220 1 time then

PAUSE 10 'then wait 10 ms

NEXT

LOOP

This works fine with the motors accelerating smoothly as the resistance of the ad5220 from W1 to B1 decreases and the duty cycle increases.

Then the motors slowing down as the opposite happens.

Problem is when I run the below pre-programmed type code It acts erratically speeding up to full speed at random times or slowing down.

Batteries are fresh and the bug seems to have no real pattern. If I redo the program right after it may show different symptoms or none at all.

I think I may need a large capacitor across the power lines of select chips to prevent the motors turning on at speed 10 from a stop possibly overloading the MCU....idk.

' {$STAMP BS2}

' {$PBASIC 2.5}

OUTS = %0000000000000000

DIRS = %1111100000100110 'set all pins with wires attached in schematic to outputs.

' -----[noparse][[/noparse] Variables ]----------------------------------------------------------

address VAR Word ' Stores EEPROM address.

instruction VAR Word ' Stores EEPROM instruction.

DPold VAR Byte 'store digital pot position old 0 - 127

DPnew VAR Byte 'store new position for digital pot. 0 - 127

DPset VAR Byte ' store calculated difference and apply pulse to ad5220

newspeed VAR Nib ' store value 0 - 10 as pulled from EEPROM by instruction

oldspeed VAR Nib 'store old valuse of 0 - 10

UD PIN 11

CLK PIN 12

_555 PIN 15

SPKR PIN 5

' -----[noparse][[/noparse] EEPROM Data ]--------------------------------------------------------

DATA 5,"FFPBBP",6,"FFPBBP",7,"FFPBBP",8,"FFPBBP",9,"FFPBBP" ,10,"FFPBBPQ" ' Navigation instructions.

' -----[noparse][[/noparse] Initialization ]-----------------------------------------------------

HIGH UD 'move wiper toward A side

PWM CLK, 255, 127

FREQOUT SPKR,200,3200

FREQOUT SPKR,200,3700

FREQOUT SPKR,200,4200

PAUSE 2500

' -----[noparse][[/noparse] Main Routine ]-------------------------------------------------------

'This program looks in the DATA and if Its a number it compares it to the last number and scales the numbers to 0-127 from 0 - 10

'and then gets the difference which it pulses to the AD5220 Which changes the duty cycle of the PWM of the 555. With this setup

' The tank can not make sweeping turns. A future design will have two 100k digital pots controlling a 556 for the two tracks. I burned up one

'AD5220 by using a 220ohm resistor on the AD5220 W1 input instead of a 2.2k , Which caused 20 mA to flow through something rated at no more than 5. oops.

'If the DATA is a Letter it sees which routine to call. And each routine turns the corresponding direction control pins on the L298 chip on.

DO UNTIL (instruction = "Q")

READ address, instruction ' Data at address in instruction.

address = address + 1 ' Add 1 to address for next read.

SELECT instruction ' Call a different subroutine

CASE "F": GOSUB Forward ' for each possible character

CASE "B": GOSUB Backward ' that can be fetched from

CASE "L": GOSUB Left_Turn ' EEPROM.

CASE "R": GOSUB Right_Turn

CASE "N": GOSUB BRight_Turn

CASE "V": GOSUB BLeft_Turn

CASE "P": GOSUB pause_

CASE 0 TO 10: GOSUB speed

ENDSELECT

LOOP

DIRS = %0000000000000000

END ' Stop executing until reset.

' -----[noparse][[/noparse] Subroutine - Forward ]-----------------------------------------------

Forward:

OUTS = %1100000000000010 ' Forward subroutine.

PAUSE 500

RETURN

' -----[noparse][[/noparse] Subroutine - Backward ]----------------------------------------------

Backward:

OUTS = %1010000000000100 ' Backward subroutine.

PAUSE 500

RETURN ' Return to Main Routine loop.

' -----[noparse][[/noparse] Subroutine - Left_Turn ]---------------------------------------------

Left_Turn:

OUTS = %1000000000000010 ' Left turn subroutine.

PAUSE 500

RETURN ' Return to Main Routine loop.

' -----[noparse][[/noparse] Subroutine – Right_Turn ]--------------------------------------------

Right_Turn:

OUTS = %1100000000000000 ' right turn subroutine.

PAUSE 500

RETURN ' Return to Main Routine section.

' -----[noparse][[/noparse] Subroutine – BRight_turn ]--------------------------------------------

BRight_Turn:

OUTS = %1000000000000100 ' right turn subroutine.

PAUSE 500

RETURN ' Return to Main Routine section.

' -----[noparse][[/noparse] Subroutine - BLeft_Turn ]---------------------------------------------

BLeft_Turn:

OUTS = %1010000000000000 ' Left turn subroutine.

PAUSE 500

RETURN ' Return to Main Routine loop.

'------------------------------------------------------------------------------

pause_:

OUTS = %0000000000000000

PAUSE 1000

RETURN

'---------------------------------------------------------------

speed:

LOW _555 'turn off 555 for speed calculations

newspeed = instruction ' save 0 -10 value of instruction to newspeed

DPnew = newspeed */3270 ' scale 0 - 10 to 0 -127

DPold = oldspeed */3270 'scale 0 - 10 to 0 -127

IF (DPnew) > (DPold) THEN 'figure out which one is bigger

DPset = DPnew - DPold ' find difference and save value

LOW UD 'set wiper to move toward B side to increase duty cycle

PWM CLK, 255, DPset ' apply # of pulses to CLK pin of AD5220

oldspeed = newspeed ' save value of newspeed as oldspeed

ELSEIF (DPold) > (DPnew) THEN 'figure out which one is bigger

DPset = DPold - DPnew ' find difference and save value

HIGH UD 'set wiper to move toward A side to decrease duty cycle

PWM CLK, 255, DPset ' apply # of pulses to CLK pin of AD5220

oldspeed = newspeed ' save value of newspeed as oldspeed

ELSE 'else do nothing

ENDIF

RETURN

Anyone spot any obvious problems?

Thanks!

Post Edited (Campeck) : 12/6/2009 8:42:36 PM GMT

Comments

Post Edited (PJ Allen) : 12/8/2009 1:15:45 PM GMT

Let me try that....

I'm not too sure what going on. But all my code isn't showing up in the folder I put it in. when I look for it with the attachment manager or with file explorer. But the stamp editor shows all of them.

Post Edited (Campeck) : 12/8/2009 6:48:29 PM GMT

I remember reading that the PWM command isn't a true Squarewave with a dutycycle. But a highspeed stream of 0's and 1's

That over the time period equals the duty cycle.

So I was wondering if this was affecting the AD5220 in that it wasn't seeing a clean pulse with the PWM command.

Which I had put in in favor of a FOR...NEXT loop.

But With this new speed calculation code preliminary checks indicate the code is clean of bugs.

speed: newspeed = instruction DPnew = newspeed */ 3270 IF DPnew > DPold THEN LOW UD FOR counter = DPold TO DPnew PULSOUT CLK, 1 NEXT DPold = DPnew ELSEIF DPold > DPnew THEN HIGH UD FOR counter = DPnew TO DPold PULSOUT CLK, 1 NEXT DPold = DPnew ENDIF RETURNPost Edited (Campeck) : 12/9/2009 7:39:18 AM GMT