CNC SMT Pick and Place Video Update

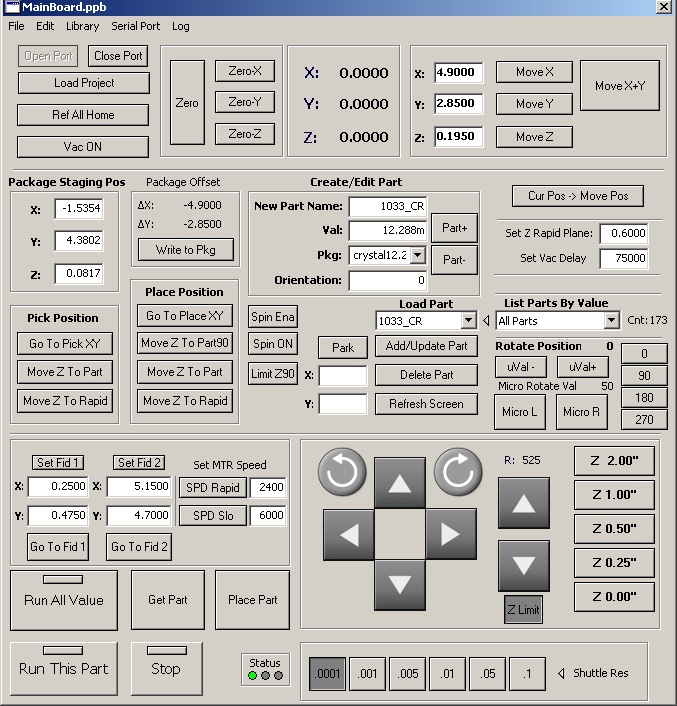

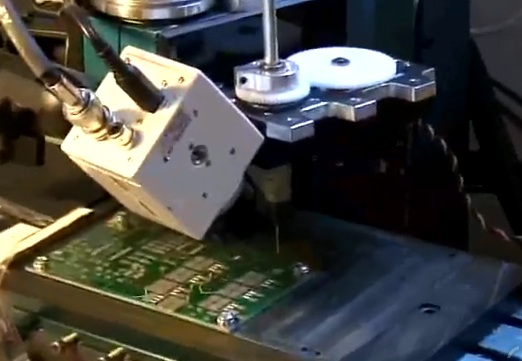

I finally got some time to edit some video I shot of the machine placing parts. It really needs 4 camera angles, and there was no way to do it on a tripod with one cam, so I apologize for the shaking. The project is a GUI that sends strings to a Propeller which drives 3 steppers and a vacuum on a small benchtop CNC machine mod'ed with a servo and syringe for picking up parts. The image is the GUI I created that imports a text file that is outputted from Eagle with X and Y for all the parts. Just a few tweaks to program in the packages for the parts plus any orientation changes, and it is smooth sailing after that. There is no auto feeder yet, I have some ideas but realistically it goes very quickly by hand with very little error. Compared to the old school method of tweezers and a hand rest, there is no comparison to how much easier it is, there is very little thought process, the app calls up the parts as you go, as one part is running just be getting the next part ready. For mutiple parts of the same value, there is a one click Run ALL value, just feed the tape and watch. This was a LOT of fun to build and is extremely helpful building my product PCBs.

Anyways, I uploaded a Hi res video, looks better in HQ.

www.youtube.com/watch?v=jW0z5Hct3xU

Here is the app screen shot:

Post Edited (Todd Chapman) : 11/9/2009 5:00:21 AM GMT

Anyways, I uploaded a Hi res video, looks better in HQ.

www.youtube.com/watch?v=jW0z5Hct3xU

Here is the app screen shot:

Post Edited (Todd Chapman) : 11/9/2009 5:00:21 AM GMT

Comments

Have you thought about using a vacuum tank and selonoid valve to turn on and off the vacuum and putting that awful sounding vacuum motor way way far away so I can hear the stepper motors and servos go swish zzzz click. For something with such nice precision it should sound like a nice sports car.

What brand is the small benchtop CNC machine or is it a home brew as well?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Think Inside the box first and if that doesn't work..

Re-arrange what's inside the box then...

Think outside the BOX!

I'm very impressed with your work so far.

I have a few questions........

Have you considered future operations, and how you will accomplish those?

I was specifically wondering about rotation of a part, and squaring of the part to the placement.

I like your approach so far. I also recognize the machine. I wouldn't talk about it either. A partner and I started a CNC business with one of those......and bought a different machine right away. It was good for rough medium fast prototypes, but not much else.

James L

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

James L

Partner/Designer

Lil Brother SMT Assembly Services

Are you addicted to technology or Micro-controllers..... then checkout the forums at Savage Circuits. Learn to build your own Gizmos!

As far as rotation, on a chip like a QFN I do a little micro rotation, I just drop those to about 90% of the move to the PCB, tweak it left or right by small amount of degrees and place it. It takes maybe 15 seconds to tweak in a fine pitch part. Larger chips place just fine. I don't square any passives, maybe just a slight amount here and there on IC's. I set up a micro rotation feature to move left or right just a tad or as you set it to move. Out of a few thousand parts now I don't have any issues yet. It gets pretty easy after a few boards. In a month or so I will have someone doing it for me in house along with milling other parts.

This machine works great after you rebuild it from scratch, I have new motors, nuts, screws, controller and Geckos. It comes with a solid Taig spindle already so that is a plus.

Post Edited (Todd Chapman) : 11/11/2009 6:25:08 AM GMT

I was just wondering how far you were going to take the machine operation. It is pretty neat for a home built solution.

James L

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

James L

Partner/Designer

Lil Brother SMT Assembly Services

Are you addicted to technology or Micro-controllers..... then checkout the forums at Savage Circuits. Learn to build your own Gizmos!

Cool, keep us updated. Sounds like a neat project. I wanted to build a machine from scratch, but found a series of obstacles I didn't want to over come.

James L

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

James L

Partner/Designer

Lil Brother SMT Assembly Services

Are you addicted to technology or Micro-controllers..... then checkout the forums at Savage Circuits. Learn to build your own Gizmos!

This item http://cgi.ebay.com/MikroPrecision-inferometer-platform-PZ-06-SC-SF_W0QQitemZ370232748658QQcmdZViewItemQQptZLH_DefaultDomain_0?hash=item5633976a72

Sold for $18,000.00 the Z access is machined from a full block of aluminum, the XY table is something like .00001 tol ball screws and ball bearing slides.

He said one table listed for $1000 right now was a $30,000.00 table basically used for inspection with microscopes. I think the table has linear slides super fast movement.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Think Inside the box first and if that doesn't work..

Re-arrange what's inside the box then...

Think outside the BOX!