Very Puzzling?????

Hi All,

·

This is puzzling me and I cannot figure it out...there is something I am missing???

·

On the Propeller Demo Board (PDM) I can apply a voltage from 0 to 3.3 to the LEDs and they will light up

proportionally. So if I apply 0.1V the LED will be showing very faint light....if I apply 1.5 volts it shows

bright but not full brightness as it would when I apply 3.3 V.

·

This is exactly what I expect......

·

BUT.....on the Propeller Professional Development Board (PPDB) the LEDs do not show any light

until about 2.5V which shows as very dim....and then it is proportional dimness wise to the

voltage applied just as you would expect but all SHIFTED by 2.5 volts...so 2.7 volts is brighter and

3.0 volts is again brighter and full brightness at 3.3V

·

But....WHY????....does it only start at 2.5V and not at 0V ....

·

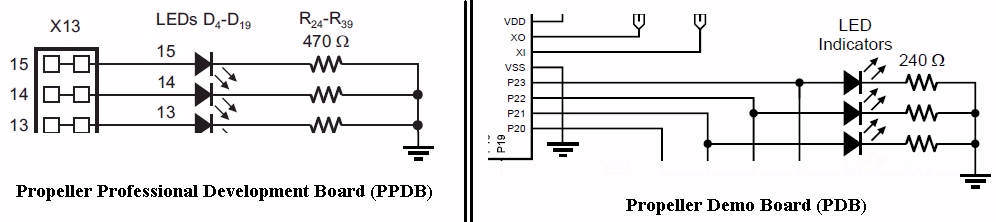

I am enclosing the Schematics for the two setups of the LEDs on both boards below....

·

This behavior does not make sense according to the electrical calcs.......the only thing I can

think of is that the LEDs on the PPDB require a minimum voltage drop of 2.5 to functions.

This is not like a normal LED.....

·

The LEDs on the PPDB are blue while the ones on the PDB are orange. But I do not see

much difference otherwise......why would the PPDB ones require such a big V drop before

they function????

·

Can someone shed a light on this????

·

·

Thanks in advance

·

Samuel

·

·

·

·

This is puzzling me and I cannot figure it out...there is something I am missing???

·

On the Propeller Demo Board (PDM) I can apply a voltage from 0 to 3.3 to the LEDs and they will light up

proportionally. So if I apply 0.1V the LED will be showing very faint light....if I apply 1.5 volts it shows

bright but not full brightness as it would when I apply 3.3 V.

·

This is exactly what I expect......

·

BUT.....on the Propeller Professional Development Board (PPDB) the LEDs do not show any light

until about 2.5V which shows as very dim....and then it is proportional dimness wise to the

voltage applied just as you would expect but all SHIFTED by 2.5 volts...so 2.7 volts is brighter and

3.0 volts is again brighter and full brightness at 3.3V

·

But....WHY????....does it only start at 2.5V and not at 0V ....

·

I am enclosing the Schematics for the two setups of the LEDs on both boards below....

·

This behavior does not make sense according to the electrical calcs.......the only thing I can

think of is that the LEDs on the PPDB require a minimum voltage drop of 2.5 to functions.

This is not like a normal LED.....

·

The LEDs on the PPDB are blue while the ones on the PDB are orange. But I do not see

much difference otherwise......why would the PPDB ones require such a big V drop before

they function????

·

Can someone shed a light on this????

·

·

Thanks in advance

·

Samuel

·

·

·

Comments

The bias voltage of LEDs varies with color... Blue LEDs typically have the highest bias voltage.

Current= (Vapplied-Vbias)/R

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

My Prop Info&Apps: ·http://www.rayslogic.com/propeller/propeller.htm

on the color (!) of the LED. 0.1V is not enough voltage to light any LED that I am aware of. Common values

include red (about 1.7V), yellow (2.1V), green (varies, usually about 2.5V), and blue (2.5V again?).

Jonathan

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

lonesock

Piranha are people too.

Sorry I forgot to mention that the 0.1V is not actually REAL 0.1V rather it is a PWM signal

as comes out of the Duty Mode in a Counter......(not traditional PWM but quick pulsing

as explained in the Manual...Duty Mode DAC)

Now with the LEDs on the PDB I cna go down to almost 0.1V (DAC) while with the

PPDB I cannot get the LED to light up with any thing less than 2.5V (DAC).....

So what is the difference......Unless the Orange (yellow) LEDs on the PDB have capacitance

while the Blue ones on the PPDB do not have ANY capacitance.....Is that the case

Thanks for the information about the Blue LEDs requiring 2.5V drop to function...I did not

know that ...explains the 2.5V number.......

BUT......if the Yellow requires 1.7V then I should see the same behavior on the PDB and

the LEDs should not show any light till about 1.7V......but that is not the case.....they seem

to have CAPACITANCE and thus are able to maintain the voltage level better.....

Is it the case that Blue LEDs do not have much capacitance?????

Samuel

I have just done a test on the PDB and I can set the DAC to 0.001 i.e. 0.0033 V and the LED

shows a VERY faint discernable light....so these LEDs are able to be activated

at a PWM voltage of down to 0.1% DAC output.

On the PPDB the LED shows the minimal·discernable light at 75% i.e.·2.475V..........

I cannot understand the behavior difference.....?????

Sam

I am using the DUTY MODE of the CTRA so that would be ticking at 80_000_000 Hz

I am using a·16bit resolution and thus the FreqA is set to Duty*65_536

It is the PPDB that is not working until almost 75% DAC not the PDB.....so the

capacitance of the Bread Board might actually be STOPPING the smoothing

(does not make sense)....On the PDB the LEDS are wired directly while with the

the PPDB there is the Bread boarding aspect....I am going to try direct connection

and see????

....I just did.....no difference.....still needs 75% to activate

Very PUZZLING??????

Sam

Post Edited (SamMishal) : 10/27/2009 10:50:19 PM GMT

Lawson

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Lunch cures all problems! have you had lunch?

My thinking has been all wrong.....now I see....INDEED...the capacitance actually DOES in fact hinder the

the LEDs from seeing the quick 3.3V since the capacitance is smoothing out the voltage and thus the

LEDs only see the average smoothed voltage and since the PPDB LEDs need 2.5V drop then that is what they

will have to see from the smoothed out voltage.

But on the PDB the voltage is not smoothed out and thus the LEDs will have an average brightness.

So the PPDB LEDs never get to see the 3.3V, they only receive the averaged voltage due to the capacitance...

I was thinking the other way around.....I now understand....THANKS A LOT....

It makes sense.....now....

The PPDB capacitance has also caused me trouble when I was trying to get the Microphone Sigma-Delta ADC

to work....Ugh...

This has been a very interesting thing....and all this at 80MHz....imagine the effects even with a PCB when the

frequencies are in the Giga Hz....how do these Cell phones ever manage to work???

·

Regards

Samuel

-Phil

Yes but the DUTY mode has advantages over the NCO PWM method

1- You can set and forget it while with the PWM mode you need to reset the Phs register periodically

2- It is easier to do ....just set the Frq register to a multiple of a scale depending on the resolution

3- The code required to update the Duty level is MUCH less thus giving SPIN code a lot more bandwidth to do

··· more time constrained actions.

4- When updating the Duty level @80MHz you get an almost instantaneous change, while with the PWM

··· method you have to wait until the PWM PERIOD finishes to update the level

Actually the Duty mode is perfect for what I am trying to do....the trouble is that I was trying to use the

LEDs as a quick and dirty way of verifying that the DAC is working while developing the code....too lazy to

go and get my Voltmeter and connect it·etc..... I guess I need to use my DMM more often....

@Localroger,

I did try the PPDB with the RCSlow speed and it WORKS....just like you suggested...it IS the high speed that

causes long leads to manifest capacitance beyond what you might expect..... ABSOLUTELY.....imagine if we had to wire up 8 μCs with shared RAM and at 80MHz.......endless trouble

from all aspects.....if it can be done at all....

....The Propeller is GREAT....no doubt about it whatsoever.....

Thanks all for the help

Samuel

Post Edited (SamMishal) : 10/28/2009 3:34:05 AM GMT