How to interface a Propeller to an IGBT? (Peltier Thermoelectric cooler contro

Hi,

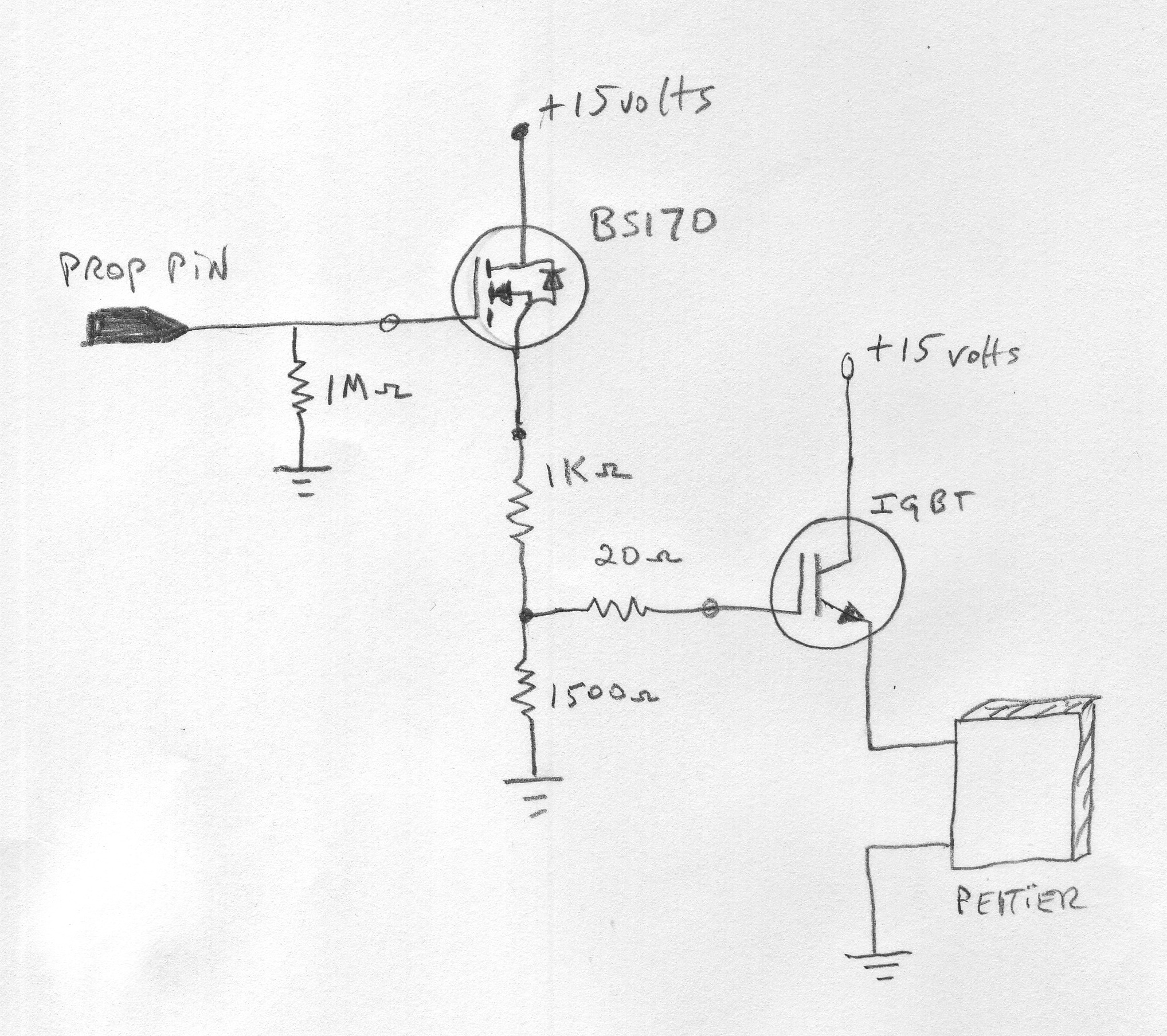

I intend to use a Propeller to drive a Peltier thermoelectric cooler using PWM. Members of the forum have suggested I use an IGBT to switch the Peltier power, and this sounds good to me. However, I'm not sure how to design transistor-type circuits, so I'm posting my idea in the attachment (PropDrivenIGBT) and casting it out there for comments or suggestions.

The Propeller pin drives the BS170 (FET), which I hope will yield a 9 volt signal using the voltage divider created by 1k ohm and 1500 ohm. The 9 volt driving signal then passes through the 20 ohm gate resistor to the IGBT to drive 15 volts at 10 amps, which is fed to the Peltier. I'm just guessing at the value for the gate resistor.

I have attached the data sheets for the BS170 and the IGBT that I plan to use, but these are just guesses so if you have other suggestions, please let me know.

thanks a million,

Mark

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Watching the world pass me by, one photon at a time.

Post Edited (ElectricAye) : 8/30/2009 12:16:14 AM GMT

I intend to use a Propeller to drive a Peltier thermoelectric cooler using PWM. Members of the forum have suggested I use an IGBT to switch the Peltier power, and this sounds good to me. However, I'm not sure how to design transistor-type circuits, so I'm posting my idea in the attachment (PropDrivenIGBT) and casting it out there for comments or suggestions.

The Propeller pin drives the BS170 (FET), which I hope will yield a 9 volt signal using the voltage divider created by 1k ohm and 1500 ohm. The 9 volt driving signal then passes through the 20 ohm gate resistor to the IGBT to drive 15 volts at 10 amps, which is fed to the Peltier. I'm just guessing at the value for the gate resistor.

I have attached the data sheets for the BS170 and the IGBT that I plan to use, but these are just guesses so if you have other suggestions, please let me know.

thanks a million,

Mark

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Watching the world pass me by, one photon at a time.

Post Edited (ElectricAye) : 8/30/2009 12:16:14 AM GMT

Comments

If you want to go for efficiency, I'd go the MOSFET driver route... You can get some MOSFET driver chips as samples from TI. A good P/N is UCC27322. This chip can source/sink up to 9A, meaning insanely fast turn on/off times. You just feed it a 3.3V signal(or 5V works fine too), and it does the switching of the MOSFET.

Okay,

that makes sense to me. I just pulled those values out of my hat, anyway.

I'll give that MOSFET driver a look-see, too.

thanks again,

Mark

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

My Prop Info&Apps: ·http://www.rayslogic.com/propeller/propeller.htm

Well, that's a very good point! Oops, I think that divider is an artifact from a previous design. So I guess all I need (instead of the 1k and 1500 ohm resistors) is a resistor to limit current going through the BS170. That would certainly make it simpler and, I suppose, faster, too.

thanks, Rayman!

Why not use a Power MOS-FET like the IRLZ14 (10A) or IRLZ34 (30 A), they have a low gate threshold which can be driven directly with 3.3 V logic signals. See attached schematic.

Andy

Andy,

I thought that the threshold voltage on the data sheet was the voltage needed at its gate to cause the FET BS170 to switch. I was hoping to use a FET so I wouldn't have to really think too much about the design. Am I reading the data sheet incorrectly?

As for directly driving a MOSFET via the Propeller: the problem is that when you want the MOSFET to switch large amounts of current (10 amps), you must apply more voltage to the gate than for low current operation. See Figure 3 of the IRLZ14 data sheet I have attached. The Propeller's 3.3 volts could make your suggested MOSFETs switch maybe about 1 amp, but for 10 amps, I think it would require about 5 volts or so, therefore I think I need another way of driving the MOSFET. At least that is the way I read the data sheet for the IRLZ14. Looking at the data sheet for IRLZ34, Figure 3 suggests that switching 10 amps at 15 volts would be very close to 3.3 volts, so I'm guessing it's probably a little too close for comfort at that current level.

thanks for looking this over for me,

Mark

Post Edited (ElectricAye) : 8/24/2009 5:11:28 AM GMT

A resistor connected to +12V that the Prop drives low. If high, the Prop-pin goes to High-Z. But the gate will be driven until the Prop booted, if that's a problem.

IGBTs arent that much caps on the gate like MOSFETS.

You could also use a gate-driver IC, makes things simpler.

Nick

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Never use force, just go for a bigger hammer!

The DIY Digital-Readout for mills, lathes etc.:

YADRO

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

My Prop Info&Apps: ·http://www.rayslogic.com/propeller/propeller.htm

Your right, the Gate-Source voltage to Drain current charactersistic is in the datasheet, that ElectricAye has postet. See attachment 1.

ElectricAye

Yes the IRLZ14 needs 4.5V at the gate for 10A. I don't knew how many Amps you need. But with the IRLZ34 it should work, and there are also higher current members of this FET family (IRLZ44 ...).

Attachement 2 shows an extended circuit which works with 15V gate voltage on second Transistor. The resistor value depends on the needed switch time and the gate capacity. The resistor at the BS170 turns the Peltier off while the Prop Pin is an input (at Reset).

Consider: The Peltier Element is switched on with a logic LOW at Prop output and switched off with a HIGH, in opposite to the first version.

I would try it with the first circuit, because I use this circuit with a IRLZ14 to drive a 1A valve with a PWM signal on about 50 prints, and had never an issue with it (for shure, the valve needs a parallel diode).

If 3.3V at the gate is to low, then the FET will get hot, and you can change to the second version.

Andy

Andy,

after looking this over, I've decided that your way of switching things is superior to my original idea. I can see how your method prevents me from losing voltage from a voltage drop across the IGBT. That is a wonderful idea! Also, I think that using a MOSFET to drive the Peltier is also possible now that I have shopped around for better MOSFETs, thanks to you. Anyway, I had already ordered my IGBT by the time I saw your suggestions, so I'll give my IGBT a try first and probably shift to MOSFETs if I end up building more than one of these. But your circuit suggestion above is a great relief - I thought I was condemned to dropping a few volts across the IGBT.

a thousand thanks!

Mark

I'm sorry this didn't make sense to me yesterday - it was late last night, and I was brain dead. I think this is similar to what Andy later suggested, I just didn't notice it until now.

thanks for your help,

Mark

On a recent design, I ran one of these:

http://www.datasheetcatalog.org/datasheet/toshiba/3979.pdf

I gave it a 12v supply to the "COM" pin, and I switch it on with 3.3v straight from the propeller. Since I only had a need for one channel for this device, I went ahead and soldered up and down both sides to parallel all the driver circuits. This probably slows switching by a small amount, but brings available current from 500mA to 8x500= 4A.

I have not measured what my IGBT actually pulls while switching, but it is much under that.

The attached scope-shots are my IGBT switching a perm. magnet motor at 24v @ ~10A. Orange is the propeller pin, and blue is the output of the toshiba driver. PWM is at 1.5kHz.

Anyway, just my 2c, I'm sure there are way better ways to do this, but it works for me.

Does a cooler really have to be switched that fast?

I mean if it's in the seconds range, it wouldn't make any difference. PWM seems like an absolute overkill. In the sense that PWM is in the several kHz range.

Nick

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Never use force, just go for a bigger hammer!

The DIY Digital-Readout for mills, lathes etc.:

YADRO

I did a quick google search and found some interesting information about peltiers here:

http://www.electro-tech-online.com/general-electronics-chat/25710-peltier-devices-2.html

The important thing is that these things generate more heat when PWMed. Could this be overcome by a big capacitor?

So you would be driving it with more of a constant voltage than a switched pwm. Of course, when you turn on your MOSFET to charge the capacitor the first time there will be a large current spike because the capacitor will be at zero volts.

hope this helps.

Doug

Using a mosfet driver rather than a transistor with a series resistor has the advantage of active drive to turn the gate on and off, which results in faster switching times and less power dissipation by the IGBT.

High frequency (100Hz+) PWM for a peltier cooler is overkill. Proportional control at 2Hz or less will do just as good a job of maintaining a set temperature with simpler circuitry and produces less electrical noise.

When designing control systems like this you need to take into account failure modes. If the control circuitry fails do you want the peltier cooler to be on or off? With a component failure here is no guarantee that it will end up in one state or the other, but it can be designed so one is far more likely. Ariba's second suggested circuit (peltier2) would most likely have the cooler off if the prop failed.

this is from a post I made to a different question I posted in another part of the Parallax forum:

"I'm certainly no expert on this, so I'm only going by what I've read on the internet. But apparently Peltier devices are vulnerable to mechanical fatigue, so the more often you thermally (and thus mechanically) cycle them, the faster they'll crack. When using PWM to control them, you have to get the frequency up to a level where the thermal "inertia" of the semiconductor material prevents the rapid bending stresses from fatiguing the semiconductor material. When researching whether or not to use PWM to control Peltiers, I came across some very heated debates about whether or not it was a good idea to use PWM, but it seems that the key is to use a PWM frequency of at least 2 kHz or maybe even higher. Apparently, driving them with PWM at low frequency is a quick road to thermal fatigue.

One problem I anticipate is that data sheets are from tests done with pure DC currents and so the maximum efficiencies, etc are drawn from those tests, but I'm guessing PWM will probably generate some other sweet spots because of the thermal behavior at a higher frequency."

That was from http://forums.parallax.com/showthread.php?p=834010

Anyway, this is how I understand the phenomenon. I certainly invite others to give their opinion or share their experiences.

thanks for your interest and advice,

Mark

kwinn,

Yes, that's an excellent point and I hadn't thought of that! It's critical that it fail to ON, so I guess I'm back to using a different design.

thanks for bringing that up - it would have cooked my stuff!

thanks,

Mark

And below 5 Hz, you don't save the whales!

Nick

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Never use force, just go for a bigger hammer!

The DIY Digital-Readout for mills, lathes etc.:

YADRO

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

(better efficiency = cheaper bill)

They tend to add coils, perhaps current sensors. But if you can monitor the current, you can see how your peliter reacts (and how much current your feeding) under different frequencies, and temps.

With the ability to monitor current you can feed the peltier direct(low ohm resistor), if the speed can be switched fast enough to only allow limited current to device.

Like pulsing a LED, you can toss out the resistor, if your pulsing it so that it only reaches max current, then shuts off.

You can fry that same led if you pulsed it too slow.

And if you reverse read the led, you can read if there is more or less of the same wavelength that the junction was made to emit. (using a LED to detect light)

A peltier is really just a diode. (use a peltier to detect temp / difference?)

Its all about reading the rate of fall in either voltage or current, after turning it off, this fall rate will depend on how much junction is being stimulated externally.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

TERMS OF USE: MIT License

"Permission is hereby granted, free of charge, to any pers...........................

..............................OMITTED FOR FORUM...............................................

.................. OF OR IN CONNECTION WITH THE SOFTWARE OR THE USE OR OTHER DEALINGS IN THE SOFTWARE. "

The dsp/fpga king is dead, long live the prop.

Post Edited (Clock Loop) : 8/25/2009 8:40:40 PM GMT

-Phil

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

MOORE'S LAW: The capabilities of electronics shall double every 18 months.

cloyd's corollary: Hardware is easy, software is hard.

Yarisboy,

no... no Three-Mile-Island just yet. I dropped out of touch because I had to go out of town. Your suggestion for the ACS758 current sensor is very interesting and will probably help later on when I try to find out why my design finally does TMI.

Hey, this is great! People have kept telling me that MOSFETs were the way to go but I could never find one that looked as good as an IGBT. This will certainly help me save money as I burn through Peltiers and various attempts to make this work. Many thanks, Phil.

To Tired2, hinv, Agent, Clock Loop,

thank you, too, for your inputs. The help from the forum has opened my eyes to the breadth and depth of my ignorance, but it has also given me the courage I need [noparse][[/noparse]he says, fire extinguisher in hand] to move forward with the accumulated wisdom of this thread.

thanks to everyone,

Mark

take a look at a IR6226 or similar device?

http://www.irf.com/product-info/datasheets/data/ir6226.pdf

a side question - are you intending to use the peltiers to cool your photomultipliers - or is this a different project?

- Howard

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔