DC motors upgrade

I am using the continues rotating servo that came in the boe-bot kit, I have them connected to a track set but they seem to be too weak. That is with a 7.2v battery connected to them. Isnt the torque on those servos like 43 in*oz I was wondering if I should go with a dc motor or a larger servo?. I was thinking about replacing the servos with these dc motors.

www.solarbotics.com/products/gm9/specs/

www.solarbotics.com/products/gm17/

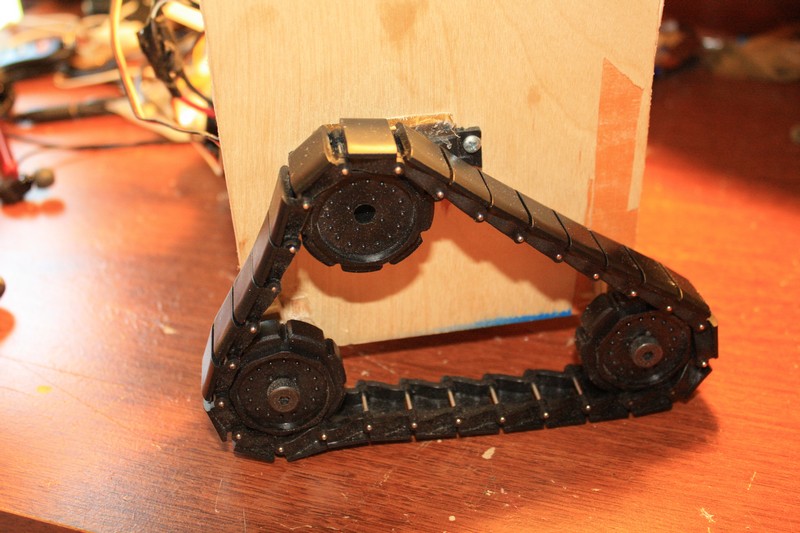

attached is what the track design looks like so if you guys think a more powerful torque motor would be better.

Thank, you

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Thank, you

Lutamos

www.solarbotics.com/products/gm9/specs/

www.solarbotics.com/products/gm17/

attached is what the track design looks like so if you guys think a more powerful torque motor would be better.

Thank, you

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Thank, you

Lutamos

Comments

I tend to find servos very slow, the gm9 with those tracks were not bad once I have cleaned up the idler wheels and bolts so they would spin freely. Note I only had 1 idler so free idlers are even more important in your case. I found that the idler will tighten on the bolt sometimes and the motor would slowdown a lot.

With the gm9 I originally used 6V battery, I uped it to 7.2V which made it faster. It still isn't the fastest thing I have seen though.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Thank, you

Lutamos

John Abshier

The more you learn, the more you find you don't know. It is neverending. Confucous 550 BC

If its fast enough without the tracks then you need more torque and either a bigger servo or the gm9 would do. If its not fast enough even without load then you need a faster motor. Most servos I have seen are about 1rps though I have seen some that are about 40% faster.If you want faster than that then a dc motor is the best bet. I have used pololu metal gearbox motors a lot and like them, see http://www.pololu.com/catalog/category/51, there is a chart of each motors rpm and torque.

Which one to use depends on the speed and torque you want.

The tracks I use with the gm9 has 19 links, yours looked like 27links so should move approx 50% faster than mine for the same rpm, with the gm9 its slow, though you can switch the motors in the gm9 to RM2 for extra speed if you need it.

As John mentioned if you use a dc motor then you need a driver, I have used the L293D with the gm9 and pololus mini-metal motors. If you use the RM2 with the gm9 you probably need to use the l298 or mc33887 drivers both work well for a slightly higher powered motor.

Post Edited (Prettybird) : 7/27/2009 1:30:20 AM GMT

www.parallax.com/Store/Accessories/MotorServoControllers/tabid/160/CategoryID/35/List/0/Level/a/ProductID/491/Default.aspx?SortField=ProductName%2cProductName

I was looking at servos pricing they seem bit to expensive for what I am wanting here since there like 35puls. With two gm9 motors and the motor controller be about $40ish. I am thinking of buying the dc motors since servos are too costly.

Thank you for your advise!

Nice robot prettybird, what is that Cylinder shaped thing above the ping sensor?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Thank, you

Lutamos

Why would that be?

Rich H

I would love to use servos though but there too expensive. I would like to keep this motor upgrade around $20 since I am just a college student. I take it with the servos with metal gears would I have to take a Dremel tool to the nob stop on the gear so it would make full 360?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Thank, you

Lutamos

also take a look at http://www.phanderson.com/stamp/tutorial_5_2.html

Post Edited (Timmoore) : 7/28/2009 12:24:37 AM GMT

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Thank, you

Lutamos

http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=320396615160&ssPageName=STRK:MEWNX:IT