Soldering Challenge: How would you solder THESE???

xanatos

Posts: 1,120

xanatos

Posts: 1,120

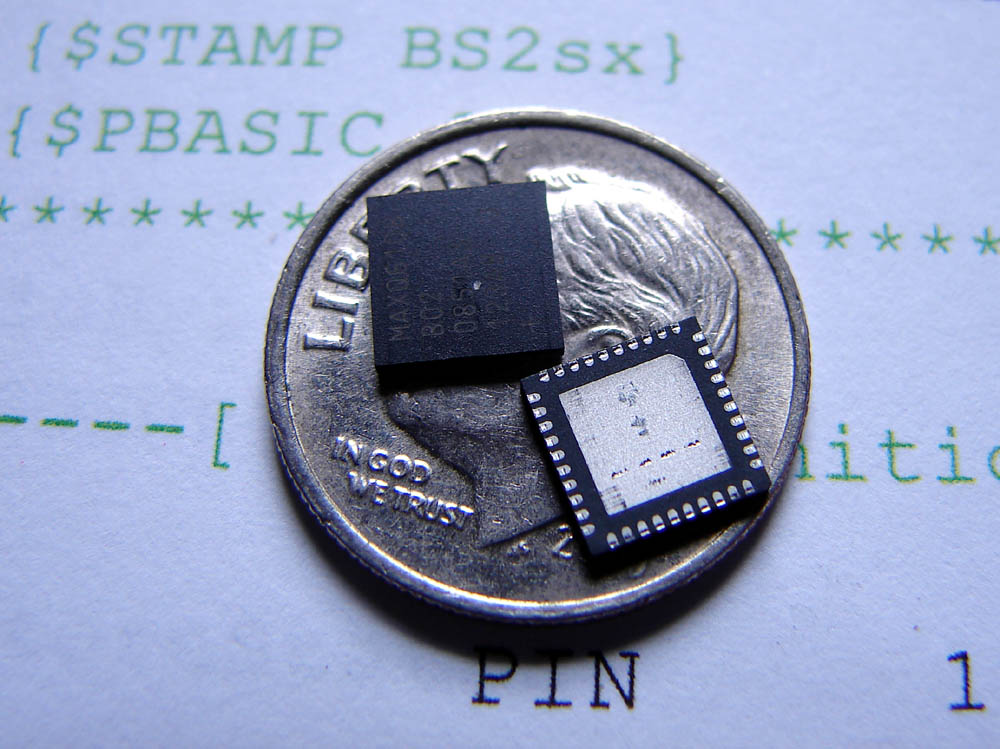

The picture says it all.· MAXQ610B's.· Not a job for my trusty Weller....· I need to get set up with a real, high-quality professional soldering method.· Advice?· Suggestions?· Manufacturers and catalog numbers??? :-)

I can make a PC board that will handle these just fine.· Just can't solder 'em...

Thanks,

Dave

I can make a PC board that will handle these just fine.· Just can't solder 'em...

Thanks,

Dave

Comments

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

propmod_us and propmod_1x1 are in stock. Only $30. PCB available for $5

Want to make projects and have Gadget Gangster sell them for you? propmod-us_ps_sd and propmod-1x1 are now available for use in your Gadget Gangster Projects.

Need to upload large images or movies for use in the forum. you can do so at uploader.propmodule.com for free.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

propmod_us and propmod_1x1 are in stock. Only $30. PCB available for $5

Want to make projects and have Gadget Gangster sell them for you? propmod-us_ps_sd and propmod-1x1 are now available for use in your Gadget Gangster Projects.

Need to upload large images or movies for use in the forum. you can do so at uploader.propmodule.com for free.

I've squeeked by the past few years with a Weller iron with a tip I made myself that is basically a needle ground into a chisel tip, and with a magnifying glass, I have been able to solder "regular" SMT style chips (like the 74xx series) with fairly nice results... but this item (and likely many more to come) are simply beyond that possibility.

I'll go find the SM soldering thread. T^hamks!

Dave

There was nothing there about the stencil - which is what I am assuming is what prevents the solder paste from simply forming bridges between those micropads. I will be continuing to check on here, but since you've got hands-on experience doing this apparently well, is there a good tutorial to which you you would refer a beginner in this kind of microsoldering work?

Thanks,

Dave

Stencils make it easy to put the right amount of solder in the right place. Not absolutely needed but make life easier

Oharp is I believe were I get mine. Can check on spelling and take some photos of the approach

Asfor bridging solder natuarly wants to pull together. As long as you don't put to much solder on and you have solder mask on pcb it will not bridge.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

propmod_us and propmod_1x1 are in stock. Only $30. PCB available for $5

Want to make projects and have Gadget Gangster sell them for you? propmod-us_ps_sd and propmod-1x1 are now available for use in your Gadget Gangster Projects.

Need to upload large images or movies for use in the forum. you can do so at uploader.propmodule.com for free.

Leon

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Amateur radio callsign: G1HSM

Suzuki SV1000S motorcycle

not sure if this is the thread mctrivia mentions, but it's got some more info:

http://forums.parallax.com/forums/default.aspx?f=15&p=1&m=360823

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Thanks very much. Now it's off to find the reflow workstation, paste syringe, etc!

Dave

Leon

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Amateur radio callsign: G1HSM

Suzuki SV1000S motorcycle

Without the Ersa, I would use a hot air pencil to reflow the part using the same process.

Without the hot air pencil, I would determine the need for the exposed pad under the part. If the connection is not critical, I would add some thermal paste for potential heat transfer and solder the leads by hand (even though QFN parts are not designed for handsoldering). If the center pad's connection is critical, I would add conductive thermal paste, then solder by hand. (if the PCB is designed with a hole through the center of the pad, you can do as Leon mentions and solder it through the PCB.

I currently have a Propstick USB board that is waiting for a new Propeller QFN chip. I'll take pictures of the process and can post if anyone is interested. (after I make it over to Parallax to buy the chip)

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Andrew Williams

WBA Consulting

IT / Web / PCB / Audio