Fried 2 chips in 3 days. The first, my fault, the second - ????

W9GFO

Posts: 4,010

W9GFO

Posts: 4,010

A couple days ago I decided to duplicate the PE kit by making up another breadboard, I had enough spares to make another complete PE kit. Some things were located differently on my breadboard but I was very careful to get all the wiring correct. I fried it when I put the Propeller chip in and loaded a program. I had put in both regulators facing the wrong way.

I corrected this goof then removed the chip form the PE kit and placed it in the new breadboard. A program was loaded and it worked as expected. An order was placed to Parallax for a new chip.

Liking this new breadboard so much more than the small breadboard that comes with the PE kit I decided to transfer all the components from the original PE kit to yet another breadboard. This time I made sure to test the voltages - I didn't want to toast another chip.

I pulled the Propeller out of the other breadboard that I had made up the other day and tried it with the new breadboard. It doesn't work!

The program will load into RAM.

The program will load into EEPROM.

I tried many different programs, all seem to load fine but I can't get any pins to output.

Pins 29 and RESn are 3.3v, and with the prop plug connected so are pins 30..31.

I put the chip back in the first breadboard and it it doe not work there either.

I have checked every connection that I can think of with a multimeter. Everything seems correct. I cannot figure out what went wrong.

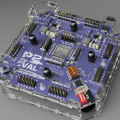

Attached is a couple images of the breadboard. I would be grateful if anyone could see what I did wrong.

Thanks,

Rich H

Post Edited (W9GFO) : 4/17/2009 6:36:01 PM GMT

I corrected this goof then removed the chip form the PE kit and placed it in the new breadboard. A program was loaded and it worked as expected. An order was placed to Parallax for a new chip.

Liking this new breadboard so much more than the small breadboard that comes with the PE kit I decided to transfer all the components from the original PE kit to yet another breadboard. This time I made sure to test the voltages - I didn't want to toast another chip.

I pulled the Propeller out of the other breadboard that I had made up the other day and tried it with the new breadboard. It doesn't work!

The program will load into RAM.

The program will load into EEPROM.

I tried many different programs, all seem to load fine but I can't get any pins to output.

Pins 29 and RESn are 3.3v, and with the prop plug connected so are pins 30..31.

I put the chip back in the first breadboard and it it doe not work there either.

I have checked every connection that I can think of with a multimeter. Everything seems correct. I cannot figure out what went wrong.

Attached is a couple images of the breadboard. I would be grateful if anyone could see what I did wrong.

Thanks,

Rich H

Post Edited (W9GFO) : 4/17/2009 6:36:01 PM GMT

Comments

My suggestion, is to call/email parallax for TWO chips. In your expiriments, you're bound to fry a chip and it's good to have two chips on hand. One to use as the backup, and another backup, while you wait for your chips to come in from Parallax.

-Phil

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module with uSD reader, and RTC options.

I have had the PLL go bad before but the chip sort of worked - just not as expected. The timing was way off. In this case I can't get any pin to go high. Would a fried PLL cause that?

Rich H

The positive connection for the rails on the right comes right from the 3.3 V regulator at the top of the board.

The PE kit does not have these bypass caps, I wonder why? I will add some though.

Rich H

I did try that. I loaded programs that used the internal clock and ones that used the xtal. There was no difference in behavior.

Rich H

back to the PC requires this). If you can load EEPROM successfully, there can't be *that* much wrong

with the chip (although of course the PLL is the usual culprit).

Are you sure the programs are loading on reset? (Slap a scope on the EEPROM clock pin).

You might attach a resistor divider to put a floating pin at 1.65V, and scope what happens when you bounce

that pin up and down.

But certainly, decide how much your time is worth, and based on that order some number of "spare"

props.

-Phil

Well yes, pins 29 and RESn are 3.3v, and with the prop plug connected so are pins 30..31.

I am not 100% sure that the programs are loading. The loading screen goes away so quickly (1/2 sec) that I can barely see the " RAM Verify" statement, but they are short programs so I suspect it is ok. Loading to EEPROM takes a bit longer - as expected.

My main concern is that there is not a problem with the breadboard such that it blows up another chip as soon as it is plugged in.

I do have a scope, kindly provide by rjo_, that I can try that with. Still learning how to use it though.

Rich H

Ok, I did that, with a 100-ohm resistor. I couldn't find one close to 75. I measured 3.31 volts everywhere. Well, everywhere that there is supposed to be 3.3 volts.

Rich H

But really, if there is 3.3V where it should be, and 0V where it should be, and NO shorts on the I/O pins, things sound good. Drop a Prop in and it should work. Just be sure of the voltages and shorts, first...

I did have a few problems with AVRs on breadboard and always assummed that it was the high capacitance of the 5 way conections to each other and/or poor connection, the pins do not go down into the cleats that much.

There was a thread a short while ago about fried props and it seemed to be blamed on poor power layouts giving rise to beggered PLLs

The pins do go where they are supposed to. It is my understanding that the crystal pins should be close to the chip. Would there be any benefit to arranging the Xtal such that both leads are right next to the chip's pins?

Rich H

I hadn't checked for shorts between pins, seems unlikely but I will check.

So far it appears that the breadboard did not cause the failure. I guess it got damaged during the handling of the chip in between boards.

Lucky me for the price drop.

Rich H

Nobody has mentioned that your Prop is straddling a power buss on the bread board.... while the connections look ok, bending the pins could introduce unnecessary stress to the chip package. Not that that should cause a problem, but in rare circumstance, I guess it could.

The standard DIP pin pitch is .6 … looks like your pushing it to .7 or .8

Edit:

I looked closer at your image and measured the pixels at aprox 100 pixels per inch.... across the prop I measured 58 pixels, so you might be ok... .6 would have measured 60.

Typically though, a breadboard won't allow you to place a chip like that without bending the pins.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

Post Edited (Beau Schwabe (Parallax)) : 4/17/2009 8:47:02 PM GMT

Just to double-check: when you tested Vdd and Vss everywhere, you did it with the Propeller pulled from the board, right?

-Phil

-Phil

The spacing is 21/32 or .66". It did not seem to be stressful for the chip. I checked, all pins make good contact with the breadboard.

Post Edited (W9GFO) : 4/17/2009 9:32:26 PM GMT

Yes, the chip was pulled.

Rich H

with the 2-pin connector for Vin. The setup/testing Lab mentions that. Plus if you are going to experiment with additional

I2C chips, add a 10K ohm resistor to Vdd and pin 6 of the EEPROM. That will make a complete I2C Bus.

Just my thoughts.

Just to be sure I slipped a piece of wire under the chip to lift it away from the breadboard and tested each pin for continuity. All pins do reach the connections beneath the breadboard.

Rich H

I've been powering it via a 9v battery. There are two caps one across 5.0v and VSS and one on 3.3v to VSS. I did not see where it said to add a cap across the 9v battery, I did however check for AC voltage. The lab mentioned something like 500 mv would be a problem, I measured less than 3 mv AC.

Rich H

BTW) That black and white Propeller closeup would make a great·desktop background if it were hi-res, and just a tad bit more in focus.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

Hmm, maybe I'll take a better picture...

I did try a different battery, and I measured each battery's voltage. One was 8.8 v, the other, 7.8 v.

I tried a brand new battery - just for kicks, but no change.

Rich H

Post Edited (W9GFO) : 4/17/2009 10:14:17 PM GMT

idea of changing the battery. This solved the problem instantly. I also once had a condition similar to yours and it was solved by replacing the EEPROM and changing the battery.

This is a dumb suggestion but check your connections going to the output devices. Sometimes you can have a problem with what is on the outside and not what is on the inside of the chip.

Say you have a damaged resistor. Yes; it is rare but it is possible.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Toys are microcontroled.

Robots are microcontroled.

I am microcontrolled.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Toys are microcontroled.

Robots are microcontroled.

I am microcontrolled.

·· I don't know if this helps, but I use the same type of breadboards in 2/3/4 sections except that my center power rails are doubled - so no 40/24 pin chips can be inserted like yours - a good idea though.· Here is a screenshot of some propellers running on the board.· I have used the 7.5v transformer output as a power source and put a 3.3 transistor/1000uF combination to get 3.3v.· For 5v I fed the 7.5 directly into a propeller usb module.· However on this setup I reuse the eeprom on the usb propeller module.· I went through your diagram and I am unable to see anything wrong with your layout.· I would suspect it to be power or failed prop chip related like everyone else states so far.· Capacitance should not be an issue as I have powered up to 3 boards (9 sections) from a single supply so far.· However I have found that the power capacitors are very important or you will see the power line harmonics higher than 3.3v causing the propeller chips to fail - but recover in a fixed circuit.

·· There is another forum thread where we all tell stories about how to fry a propeller - I accidentally put 9v for a couple seconds and that propeller now heats up in 5 sec past 60 deg because of a short.

thank you

/michael