Peltier Cooling Module

Whit

Posts: 4,191

Whit

Posts: 4,191

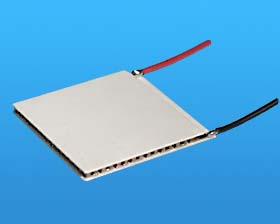

Anybody ever played with one of these?

127 couple Peltier cooling modules optimized for 12VDC. When powered one side gets cold while the other is hot. Will provide spot cooling below 0 Deg. C with proper heat sink, fan, cold plate & insulation. 70 Deg. C differential possible.

MJ1.4-127-1.14 70W (~170 BTU) heat pumping possible. 8A max, 16V max, Draws 6A@ 12VDC

L: 1-11/16" W: 1-9/16" T: 1/8" WT: .06

I saw them on sale for $17.95

Looks kind-of fun!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Whit+

"We keep moving forward, opening new doors, and doing new things, because we're curious and curiosity keeps leading us down new paths." - Walt Disney

127 couple Peltier cooling modules optimized for 12VDC. When powered one side gets cold while the other is hot. Will provide spot cooling below 0 Deg. C with proper heat sink, fan, cold plate & insulation. 70 Deg. C differential possible.

MJ1.4-127-1.14 70W (~170 BTU) heat pumping possible. 8A max, 16V max, Draws 6A@ 12VDC

L: 1-11/16" W: 1-9/16" T: 1/8" WT: .06

I saw them on sale for $17.95

Looks kind-of fun!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Whit+

"We keep moving forward, opening new doors, and doing new things, because we're curious and curiosity keeps leading us down new paths." - Walt Disney

Comments

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Mike2545

This message sent to you on 100% recycled electrons.

Post Edited (Mike2545) : 4/3/2009 2:12:39 AM GMT

It's been many years since I worked with these but here are a couple of pointers.·

You'll need a good power supply.· Those things draw a lot of current.· Also, adequate heat sinking on the hot side is essential.· Otherwise you'll get a·condition where the hot side heats up the cold side and then it turns into a runaway situation.

Chris I.

They work in reverse also.... supply heat on one side and cold on the other and they produce power. I had a couple of motors that would spin from the heat of my hand when connected to one of the Peltier devices. I stuck one over a candle and was able to power a small radio.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

(and perhaps you might have tried this)

What if I attached a couple of these to a window during the winter?

I keep it around 70 in the house, and it's anywhere from 10-30 outside

during the cold months. Would this be enough to make it worthwhile

to purchase a few to run them reverse in this manner?

I'm picturing some power generated for my basement workshop in the

winter, at the same time adding a layer of material to my windows.

OBC

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

New to the Propeller?

Visit the: The Propeller Pages @ Warranty Void.

Hmmm.... at $6.81 a square inch I don't know that I would want to find out. (That's almost $1K per square foot!) Keep in mind if your putting it on a cold window and using the temperature differential you are trying to heat the room with to create electricity, then your still at an energy loss and that "extra" energy is actually coming from your heater. I almost think it might be better to paint them black and stick them in the sun.

The Peltier devices are basically heat pumps ... but don't let the word heat distract you, cold works just as well. They essentially want equilibrium. If there is cold on one side the other side attempts by way of conduction to be cold as well... same for heat. So that cold window you want to put it on will eventually make the "warm" side pretty darn cold as well. Now, there may be some insulating barrier that is created, but I wouldn't think that it would be much.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

I'll be trying some large hose clamps when I get the time. It's certainly not as pretty, but it might work.

Any energy you get from the Peltier cell must come from somewhere, and it isn't going to come from outside the house.· Energy goes out, not in,·through the windowpane in winter.

Any energy you get from the Peltier cell will be energy you bought somewhere else to heat the house.· It takes energy to create the temperature differential you intend to use for generating electricity from the Peltier cell.· When you place the cell on the windowpane, it will provide heat conduction between the windowpane and the air in the house, thus heating the outside air a little more, making you purchase more energy to keep the house warm.

There ain't no such thing as a free lunch.

On the other hand, if you paste the Peltier cell on the windowpane and power it to cool the inside surface·of the windowpane and heat the house, the glass surface·will be cooler inside than it is now, and will conduct less heat toward the outside world.· Then (conservation of energy again) you will use less energy to power the cell than you would have lost through that part of the window glass -- a net gain for you.· You've built a heat pump.

But a piece of cardboard for insulation would do the same, and be cheaper.·

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

· -- Carl, nn5i@arrl.net

Post Edited (Carl Hayes) : 4/3/2009 1:17:36 PM GMT

Do you attach the heat sink with adhesive? On a heat pump, isn't this done with water filled cooling tubes that circulate in the soil?

It is also hard for me to understand how the thin sandwich between the two plates can provide much insulation.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Whit+

"We keep moving forward, opening new doors, and doing new things, because we're curious and curiosity keeps leading us down new paths." - Walt Disney

I haven't worked with Peltier Junction modules first hand yet, but I did study them for a potential work project a while back. Here are a couple of links to help with mounting ideas... I understand that the modules are fairly fragile and you need to apply even pressure when using a mechanical mounting method.

The photos at the bottom of this page show a typical mount for a solid-state insulated cooler application with heavy heat sinking on both sides of the module. By switching the DC polarity to the module, it will change direction of heat movement from one side to the other -- this allows the cooler to be a cooler or a warmer.

http://www.mpja.com/viewallpict.asp?dept=60

Here is an exploded view image that appears on the page from the link below that. Some good information there.

http://edge.rit.edu/content/P07440/public/TEassembly.png

http://edge.rit.edu/content/P07440/public/Home

Food for thought,

Tim

Most heat-pump systems use the same heat exchangers for heating the house that they use for cooling the house.· These are usually sets of tubes with metal fins, looking rather like a car radiator and working the same way, with fans blowing air through them.· Working in one direction, the outside air is heated and the inside air is cooled.· Working the other way, just the opposite.

The "thin sandwich" isn't supposed to provide insulation.· Its whole purpose is to transport energy from one surface to the other, not (as insulation would do) to prevent that transfer.· What the Peltier junction does is to use external (electrical) energy to control the direction of that transfer.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

· -- Carl, nn5i@arrl.net

Post Edited (Carl Hayes) : 4/3/2009 4:07:49 PM GMT

I'd stay away from the glue.· It most likely won't stand up to the thermal stress.· The exploded view that Tim-M linked to is tried and true.· The thermal interface material can be that nasty white stuff you get from Radio Shack.

Chris I.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

· -- Carl, nn5i@arrl.net

I disagree. There are really good thermally conductive epoxies. But, the price might be prohibitive. I know that T7109 is about $400/pound.

www.epotek.com/categories.asp?ID=2

Boron Nitride is (one of) the things added to most epoxies to get them to conduct heat. It is also a good electrical insulator.

I really like these Peltier devices. Too bad they are so expensive.

-Parsko

If you had hosing to connect each of the 20 rows together in series then connect the 20 series sections in paralel you would have a water cooling system with a lot of serfice area(exact amount would be 280cm^2/cm of length) with the equivalent volume capacity of a 1cm diamiter hose(about the same as water blater systems)

if this block was well insulated and connected to the cold side of the pelture I think it could cool the water down at the same rate you could drink it.

assuming the temperature of the water was not let to go below 0C

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module with uSD reader, and RTC options.

Let's run some numbers.

Let's say we're going to use one kilogram (just over a quart) of water every five minutes, and must cool it by 20 Celsius degrees.· We've got to remove 20 Kcal (83,720 joules) of heat from the water in 300 seconds, a rate of approximately 280 watts.

Looking around, I found a Peltier device for $56.00 that could handle it --

·http://customthermoelectric.com/tecs/pdf/19911-5M31-28CZ_spec_sht.pdf·

-- so it looks feasible to me.· It will require about 20 amperes at 24 vdc, nearly half a kilowatt of power.

Let us know when you've got it working.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

· -- Carl, nn5i@arrl.net

Post Edited (Carl Hayes) : 4/4/2009 4:50:18 PM GMT

what i mean by water blader is something like this

sorry if my spelling is not very good.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module with uSD reader, and RTC options.

Copper pipes are used in many water systems, although nowadays they are not favored for drinking water. You could use a copper block, bore holes in it, and press thin stainless-steel tubing into the holes. In order to get sufficient thermal conductivity to the water, there will have to be quite a length of tubing in intimate contact with the copper block. A skillful machinist could come up with something.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

· -- Carl, nn5i@arrl.net

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Need to make your prop design easier or secure? Get a PropMod has crystal, eeprom, and programing header in a 40 pin dip 0.7" pitch module with uSD reader, and RTC options.

That takes care of the "hot" side and gitting ris of the heat. The cold side depends on what your goal is. Protable hydration bladder, cool suit or whatever.

Some typical products might include:

PC CPU Heatsink/fan·· http://www.cyberguys.com/product-details/?productid=11956

Thermal tape·· http://www.cyberguys.com/product-details/?productid=1958

Thermal adhesive·· http://www.cyberguys.com/product-details/?productid=3383

Duffer

Rich

Here is some my own notes from research and observation.

1. They are only good for spot cooling interesting things like CCD(to reduce black current), ir cameras, laser diodes and sometimes processors.

2. they are horribly inefficient compared to other heat pump tech

3. More of a novelty item. You want better go with the multi junction thermocouple plates for making power(new tech from vapor deposition of thermocouple material).

If you guys want to make power or cool something try the stirling cycle. Or even better phase change system.

Look up organic rankin cycle systems. Or free piston stirling generators. Cool thing with a stirling cycle engine is the energy can go both ways thru the system with almost no changes to the design.(can be a heat pump or generator)

Post Edited (Tesla) : 4/4/2009 7:31:46 PM GMT