Model of firewood processor with scaling

· Here is a project I've been working on and will be installed on the full-sized machine in the spring.

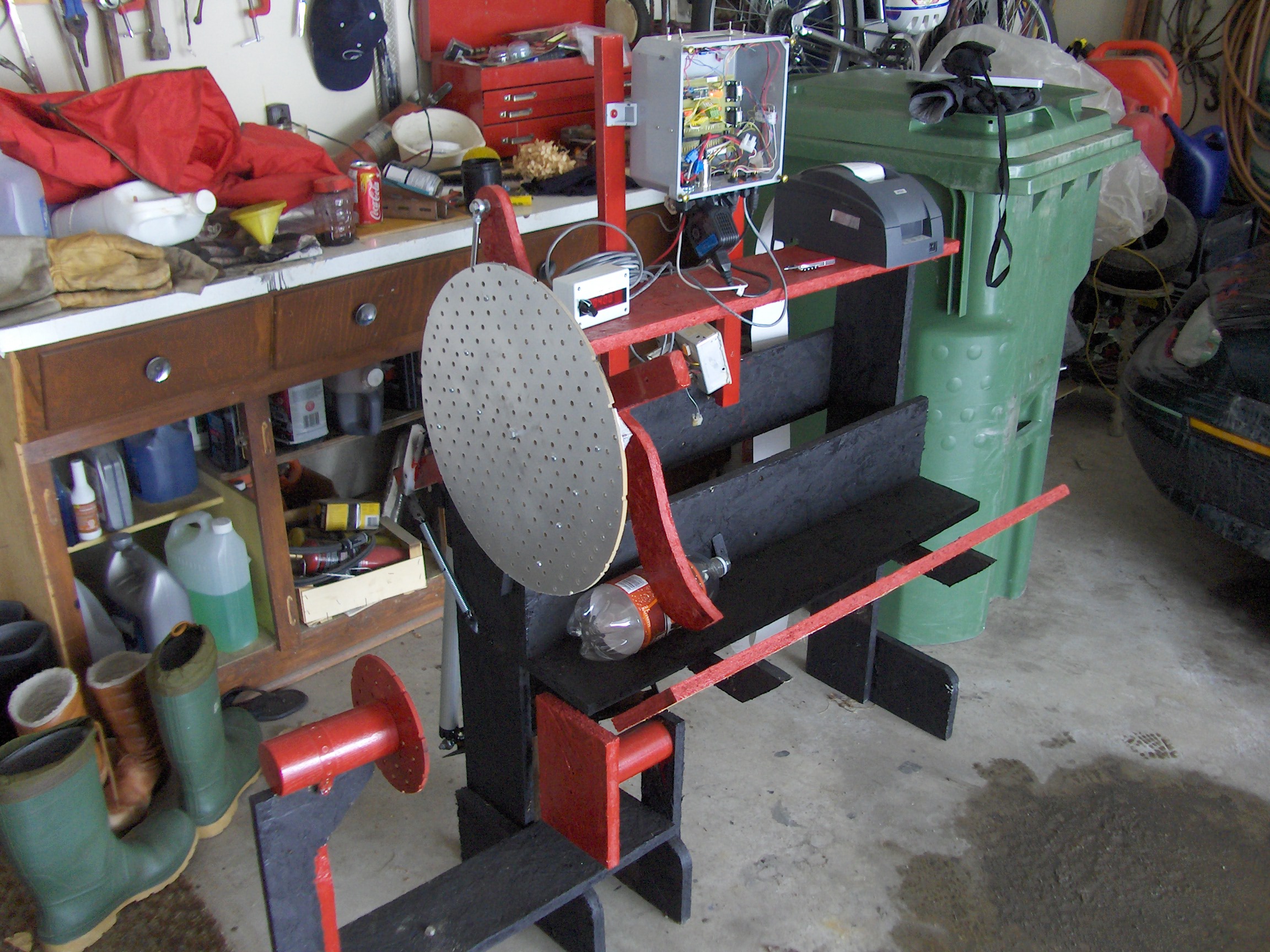

·· This is a model I built to test hardware and get the scaling algorithms working.

·· The full -sized machine is designed to take hardwod logs, cut them to length, split them and transfer them to a truck for delivery. The problem is that to get accurate measurement in cords, as required by law, the producer has to stack the wood once (and sometimes twice) in order to prove that he is delivering the number of cords he is charging for.

·· The operator wanted me to design a system which could measure the wood accurately enough to meet the regulations without having to stack and unstack the wood.

···The model shows all the key compnents: The large silver disk represents the saw blade, the log is the soda bottle, the log measuring arm is normally used to hold the log steady during cutting. The small red disk represents the log stop which sets the length of each stick. In operation, the log comes out to the log stop and the hold-down arm comes down to hold the log. The saw cuts the stick which drops down into the splitter section. A hydraulic ram splits the stick and the pieces are taken away by conveyor to the truck.

·· I used a BS2 to do the calculations, an EPSON printer to print off a load slip for the operator and the customer, A small 4-digit display to show the log diameter and the chosen log length. The system runs off the 12 volt battery normally used to start the diesel engine which drives the saw and the hydraulics. The log diameter sensor is a resistive linear pot from P3 America witha stroke of 24 inches.

·· A lot of the programming is used to format the load slip and to make sure that the tally is zeroed before a load is started. Also, a new load slip number is generated each time a new load is started and the current slip number is kept in eeprom so that the operator has unique load slips over the season.

·Cheers,

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Tom Sisk

http://www.siskconsult.com

·· This is a model I built to test hardware and get the scaling algorithms working.

·· The full -sized machine is designed to take hardwod logs, cut them to length, split them and transfer them to a truck for delivery. The problem is that to get accurate measurement in cords, as required by law, the producer has to stack the wood once (and sometimes twice) in order to prove that he is delivering the number of cords he is charging for.

·· The operator wanted me to design a system which could measure the wood accurately enough to meet the regulations without having to stack and unstack the wood.

···The model shows all the key compnents: The large silver disk represents the saw blade, the log is the soda bottle, the log measuring arm is normally used to hold the log steady during cutting. The small red disk represents the log stop which sets the length of each stick. In operation, the log comes out to the log stop and the hold-down arm comes down to hold the log. The saw cuts the stick which drops down into the splitter section. A hydraulic ram splits the stick and the pieces are taken away by conveyor to the truck.

·· I used a BS2 to do the calculations, an EPSON printer to print off a load slip for the operator and the customer, A small 4-digit display to show the log diameter and the chosen log length. The system runs off the 12 volt battery normally used to start the diesel engine which drives the saw and the hydraulics. The log diameter sensor is a resistive linear pot from P3 America witha stroke of 24 inches.

·· A lot of the programming is used to format the load slip and to make sure that the tally is zeroed before a load is started. Also, a new load slip number is generated each time a new load is started and the current slip number is kept in eeprom so that the operator has unique load slips over the season.

·Cheers,

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Tom Sisk

http://www.siskconsult.com

Comments

Actually, your uncle's machine sounds like a tree processor. See the picture in my id. It's a much older system I worked on but it also was done with a Stamp in one version. These machines now are usually used in the woods so as to leave the residue there to decompose and fertilize the new trees coming up.

Cheers,

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Tom Sisk

http://www.siskconsult.com

·

Automatic cut, split and load with a way to measure how much?

egad man, that's brilliant.

Nice time saving addition to any automatic firewood business!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Mike2545

This message sent to you on 100% recycled electrons.

I think the posts discussing two different machines may have led to a bit of feature creep!

The automatic cut to length of logs is in the full sized tree processor which can cost $350K to $500K. Its the picture in my id.

The firewood processor described in the top post is a much simpler machine. The actual splitting is done by a human operator manipulating the hydraulics.

The Stamp does the measurement and load-slip printing.

Cheers,

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Tom Sisk

http://www.siskconsult.com

·

I am reading it correctly, right? "Take full size logs, cut, split and transfer to a truck" What machine does your measurement and printing go on?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Mike2545

This message sent to you on 100% recycled electrons.

The firewood machine does all that under the direction of the operator. The measurement, of course, takes place automatically in the background by watching for the saw being activated. As each piece is cut, its length and diameter is measured, volume is computed and the tally maintained until the operator determines that the load is complete. He has an LCD display in his cab to shown him how the load is building up.

The other machine, the tree processor, does indeed automatically delimb and measure the logs to length and can be set to automatically cut if the operator wishes. It can also maintain a tally of volume or pieces, depending on what the operator wants.

Tom

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Tom Sisk

http://www.siskconsult.com

·

Very cool!!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Mike2545

This message sent to you on 100% recycled electrons.

Otherwise, I'd be running a hot-dog stand on some nice warm beach [noparse]:)[/noparse]

Cheers,

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Tom Sisk

http://www.siskconsult.com

·

Now time for me to get back to my hot dog stand

Jeff T.