Weekend PCB cutting project...

Beau Schwabe

Posts: 6,576

Beau Schwabe

Posts: 6,576

Ok, so there is probably a much better way to do this, but I wanted to share anyway.

·

I ordered some PCB boards from ExpressPCB (www.expresspcb.com ) and originally I was just going to add a bunch of dummy thru-holes to act as a perforation line to break the boards when I received them but there is a limit as to how many holes you can have drilled.

·

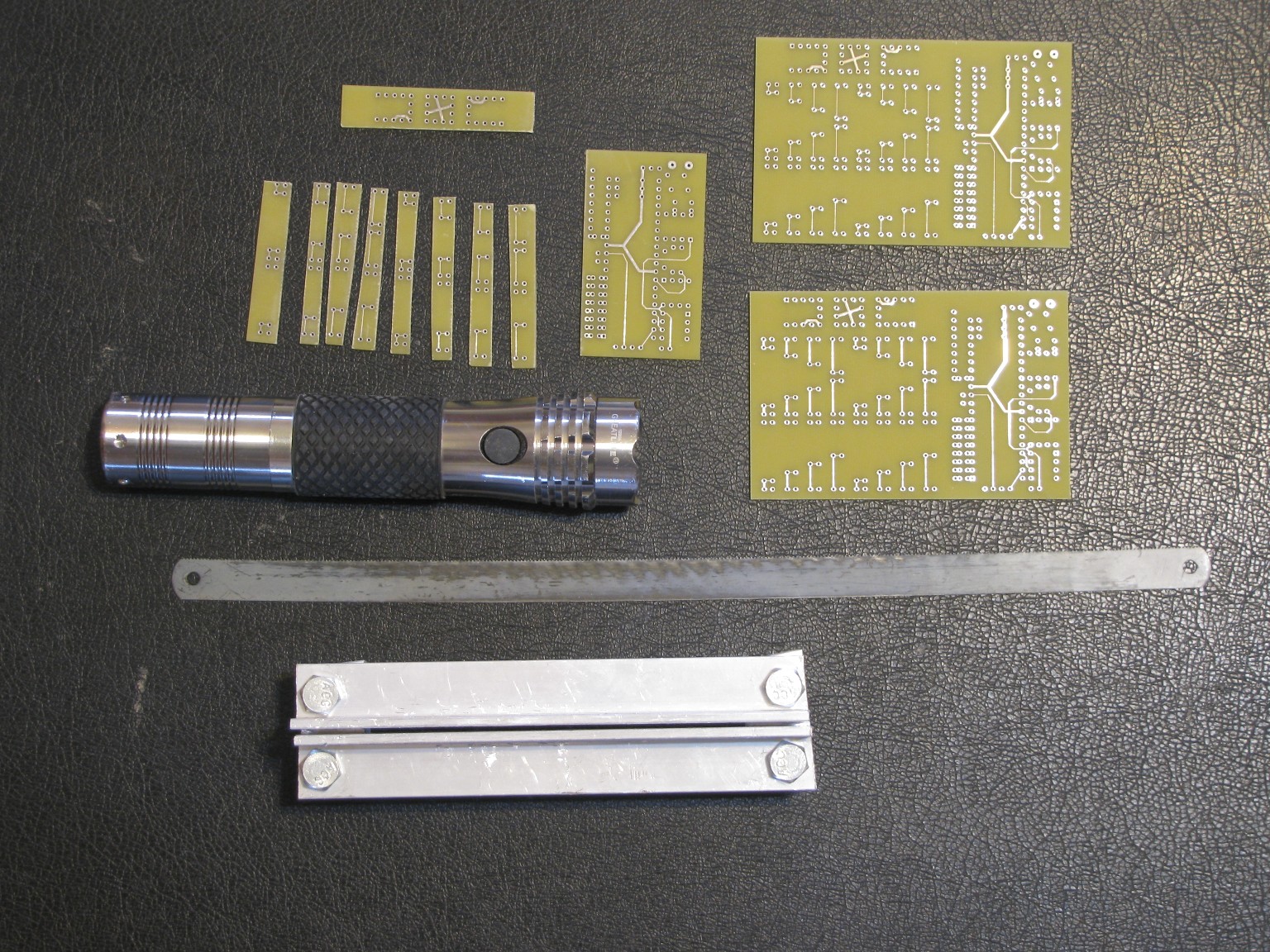

Plan B - I received the boards (un-cut) and decided to make an apparatus to cut them using 3/4·inch·right angle stock aluminum.· Combined with a·bright flashlight to see through the PCB board to check and re-check the alignment and a hack-saw blade, it·worked like a champ.· Although the cut pieces are not exact, there was a bit of a learning curve there, they are close enough for the proto-type I will be using them for.· (Check Soon in the completed projects section of this forum.)

One board down, two to go... I'm open for any suggestions or ideas that would make this easier.

·

···

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

·

I ordered some PCB boards from ExpressPCB (www.expresspcb.com ) and originally I was just going to add a bunch of dummy thru-holes to act as a perforation line to break the boards when I received them but there is a limit as to how many holes you can have drilled.

·

Plan B - I received the boards (un-cut) and decided to make an apparatus to cut them using 3/4·inch·right angle stock aluminum.· Combined with a·bright flashlight to see through the PCB board to check and re-check the alignment and a hack-saw blade, it·worked like a champ.· Although the cut pieces are not exact, there was a bit of a learning curve there, they are close enough for the proto-type I will be using them for.· (Check Soon in the completed projects section of this forum.)

One board down, two to go... I'm open for any suggestions or ideas that would make this easier.

·

···

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

Comments

·

I have a table saw, but the blade width is too thick... the hack-saw blade width is about 1/32nd of an inch, and my gap in the cutter guide is about 3/64th of an inch.

·

I don't have access to a band saw, although I have used them in the past... seems like it was difficult to keep a straight line, but perhaps that comes with practice. [noparse]:o[/noparse])

Thanks

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

This is how I did it before I got my CNC mill:

1. When you lay out the boards, include the board outline among the traces. This makes it easier to see what you're doing when you cut them.

2. Leave a gap between boards to give you some headroom to work (and allow for cutting mistakes).

3. Cut well outside the board outlines.

4. Put each cut board in a bench vise with the marked outline flush with the top of the vise.

5. File each side down until you're filing the vise top.

6. By now, anything that's left of the copper board outline will be easy to peel off.

As an alternative to 4-6, you can also use a bench-mounted disk sander. The trick is to turn it on briefly, then off, and do the sanding while it's unpowered. Otherwise, you will burn the fiberglass.

Oh, yes, one more thing: anytime you create fiberglass dust, be sure to wear a dust mask! The stuff is vile.

-Phil

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

When the going gets weird, the weird turn pro. -- HST

1uffakind.com/robots/povBitMapBuilder.php

1uffakind.com/robots/resistorLadder.php

worth every penny

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

It's Only A Stupid Question If You Have Not Googled It First!!

Score and break. Use your guide clamp, and with a sharp rigid utility knife, make some fairly deep scores into the board on both sides. A quick snap after and a fine file for touch up is all that is required. Go easy on the first scoring to establish the straight guide line. It does take a little practice, so use some scrap board to try first.

**

@Brian Carpenter,

That's a little more involved than I wanted to get for test run that was just enough to make two.

@kelvin james,

I thought about scoring, but some of my cut pieces measured only 3/16ths of an inch wide, that would have been tough.

@Zoot,

A dremel was my first thought, I was thinking a fixture of some kind resembling a mini table saw.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

That's what I do. The blade gets blunt very quickly, so I sharpen it with a diamond hone. They then last indefinitely.

Leon

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Amateur radio callsign: G1HSM

Suzuki SV1000S motorcycle

I picked up a cheap one at Biltema(Scandinavians should know this shop well... ).

As long as it's capable of cutting a sheet of A4/Letter format lengthwise, you should have enough leverage on the arm to cut a thin board with no problems.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Don't visit my new website...

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

-Paul

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Signature space for rent, only $1.

Send cash and signature to CannibalRobotics.

The band saw cost less at Home Depot than a single Miniboard order from ExpressPCB.

That reminds me, I've gotta order some PCBs I laid out last week.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

· -- Carl, nn5i@arrl.net

If you make the appropriate jig to hold it steady and straight, its the best bet.