Sensor

Tumbler

Posts: 323

Tumbler

Posts: 323

Hello,

I want to measure the volume water in a tank.

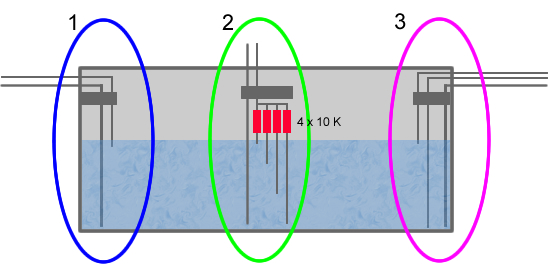

I have tried some methods (see picture)

But i want to know if there is another solution to get this work wih only 2 wires.

What i want is a value from 0 (empty) to 100 (full).

I have seen an article with the ping))) but i want to use the ping for it [noparse]:)[/noparse]

I want to measure the volume water in a tank.

I have tried some methods (see picture)

But i want to know if there is another solution to get this work wih only 2 wires.

What i want is a value from 0 (empty) to 100 (full).

I have seen an article with the ping))) but i want to use the ping for it [noparse]:)[/noparse]

Comments

Yet another way would be to use a potentiometer with a float mounted on an arm. The float rises, turning the shaft of a potentiometer (or moving a linear pot directly), and the resistance changes. Many automotive fuel gauges work that way.

Another way would be to use, say, an ultrasonic distance-measuring device to measure the distance from the top of the tank to the surface of the liquid.

Another way would be to reflect a collimated light beam from the surface of the liquid at a row of photoresistors on the far wall. Seeing which photoresistor was illuminated would allow you to know the approximate depth.

If the liquid is transparent but colored, another way would be to put a mirror on the bottom and shine a light onto the mirror, which would reflect it back to a photodetector mounted next to the light source at the top. The light would go down through the liquid, bounce off the mirror, and come back up to the photodetector. Its intensity would be a measure of the depth. The shallower the liquid, the brighter the returning beam. I once designed a colorimeter that way. It measured, not the depth, but the color density of the liquid, which was diluted human blood -- we were actually measuring the hemoglobin concentration (the darker the liquid, the greater the hemoglobin concentration).

You could, instead, use a load cell to measure the weight of the liquid. You could design your own, using a spring and a linear potentiometer.

A little brainstorming would probably lead to ten or twenty additional approaches.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

· -- Carl, nn5i@arrl.net

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Chris Savage

Parallax Engineering

Leon

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Amateur radio callsign: G1HSM

Suzuki SV1000S motorcycle

How big is your tank?· ... A capacitive sensor·usually works well.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

The water amount is +- 10 cm, and thats the maximum.

I need it to automate a humifier.

Beau, a capacitive sensor?

I will try the idea of Remmi (with the potentiometer strip) ·later this week.

·

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

· -- Carl, nn5i@arrl.net

A small speaker and condensor mic, measure what frequency is the loudest. That should be the resonance frequency and you should be able to determine the fluid level from that. More water, high resonance frequency, less water, lower resonance frequency.

Do you think that would work ?

Bean.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

"The welfare of the people in particular has always been the alibi of tyrants." ~ Camus

www.iElectronicDesigns.com

·

The way to measure it would not be the loudest sound, though.· Much better to measure the peak impedance at the transducer.· Depending on the Q of the cavity, there will be a greater or lesser peak in the impedance at resonance.· It takes many fewer parts to measure this than to measure the loudness of a sound.

But I still think that if all one wants to do is keep a tank from running dry, a simple float valve would be easier.· Or one could just invert a bottle with its neck opening at the level one desires to keep.· When the liquid surface gets below the bottle's mouth, it goes glug and lets a little air into the bottle, and a little water comes out.· This is the method used in many water coolers (the ones with a 5-gallon bottle turned upside down and resting on top).

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

· -- Carl, nn5i@arrl.net

Post Edited (Carl Hayes) : 12/9/2008 9:17:48 PM GMT

-Phil

(1) not only does the impedance of the speaker peak at resonance of the system to which it is attached·(speaker and cavity, in this case), but it also changes character,·from capacitive (just above resonance) to inductive (anywhere below resonance).· You could design an oscillator that would run at·resonance (using the speaker as a resonator, or tank), and·put a counter on it.

(2) but·any of these schemes would be noisy.· Ouch.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

· -- Carl, nn5i@arrl.net

"Beau, a capacitive sensor?" -· Yes, check this thread out ...

http://www.parallax.com/Portals/0/Downloads/docs/cols/nv/vol1/col/nv27.pdf

[noparse][[/noparse]Beau Schwabe feeling old] ...WOW, was that project really 11 years ago [noparse][[/noparse]/Beau Schwabe feeling old]

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

Looks intresting...

But if it's gunna work with only 10 cm high waterlevel ?

I will test it in the weekend or so.