My first robot

Hi all, I wanted to finally contribute something to the forum so here's my first robot and a long-winded

description:

To be honest I'm a little embarassed to present this robot.

Its about as ugly as they get... the wiring looks like spaghetti and

the components are either all spare junk or parts from various BOE-bot kits.

The original concept was a robotic "head" that sits on my desk so I can play

with AI and human interaction. It expanded into a hodge-podge robot with

several features.

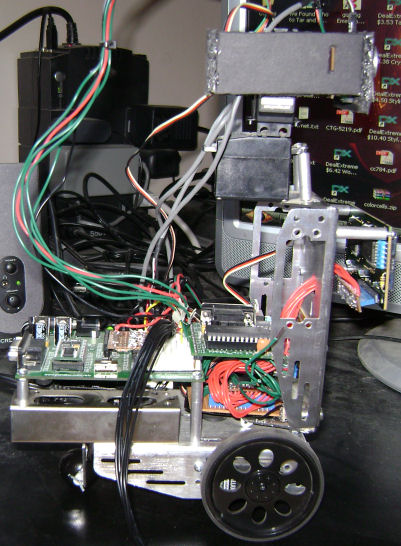

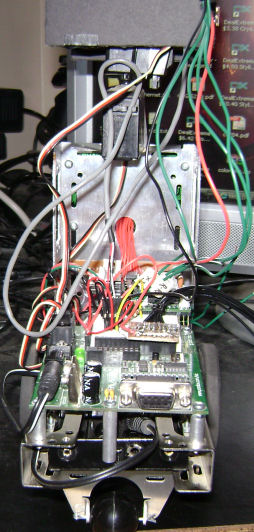

To start, it uses two BOE-bot frames for its lower and upper body. There are

also two computer drive bay expanders to support the extended BOE platform.

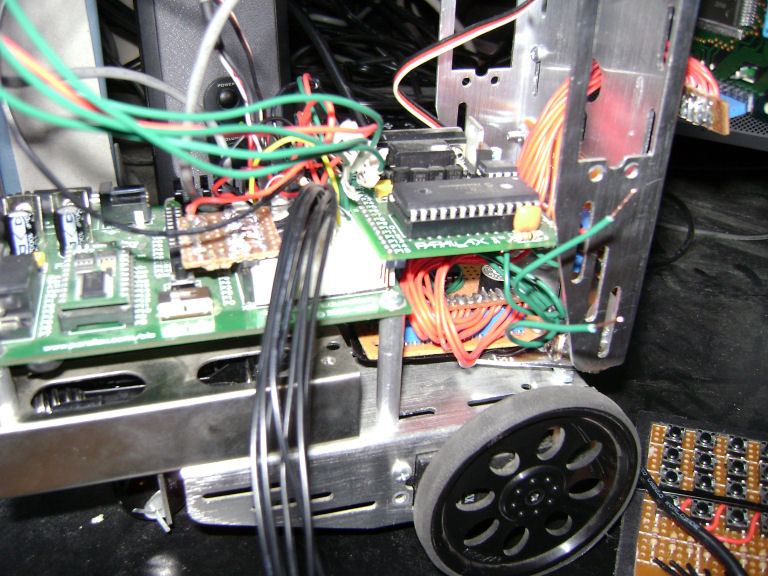

On the BOE are a BS2 and a BS2 OEM that control the robot (Although I am toying

with the idea of adding a second BOE upside down under the existing one... but

I can't think why I'd need it).

The main focus is the robot's head. Its basically a pan and tilt turret with

sensors on it.

The two continuous rotation servos are attached to each other for the pan/tilt

movement, and the head its self is made out of foamboard (a non-conductive

foam core with paper on both sides used for arts and crafts).

The foamboard is a temp solution, I want to eventually replace it with expanded

PVC.

In the head is a homemade board that contains two IR leds (wired together), two

IR receivers, a 5-led array and a transistor-capacitor circuit that allows the

led array "mouth" to blink fast on - slow off with the center brightest so it

has a bit of a johnny-five "lip lights" effect.

Also in the head are a ping and a tilt switch device (ripped out of an Elmo toy)

that will eventually let me detect the angle of the tilt and prevent the robot

from wringing its own neck.

I haven't wired up the tilt switch yet as I'm hoping to replace the servos with

something a bit better soon, perhaps motors with encoders or stepper motors.

I'd like standard servos, but of course, they are kind of expensive.

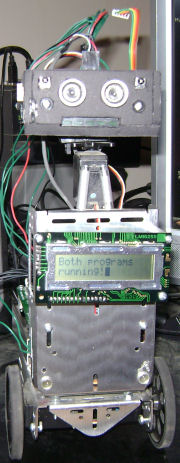

On the front is a 2x16 LCD powered by Peter H. Anderson's #117 serial LCD backpack

on a custom board that takes advantage of all the backpack's features.

The backpack is located below the BS2OEM and connected via a homemade cable to

the LCD out front.

I also use two of the general purpose outputs of the #117 to power a simple

transistor circuit that switches on two 6volt lamps mounted on the bottom front

of the robot and act as headlights.

The whole thing will eventually be controlled by a simple AI that I'll get around

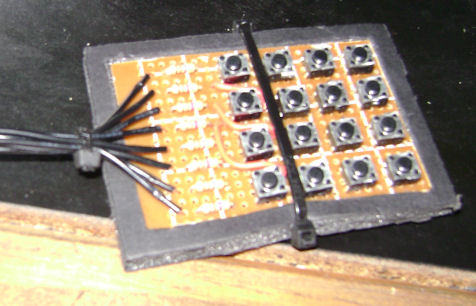

to making sometime after I replace the servos. For now its controlled by a homemade

matrix keypad connected to pins 0-7 on the BOE.

Future plans:

1) Writing the AI so I can get rid of the ugly matrix keypad.

2) IR remote control (again, so I can lose the matrix keypad).

3) Dual power sources to extend battery life (two 4x AA holders should work)

4) A top "headboard" that will let me control the ping, IR/mouth board and tilt

·· switch with just one wire coming off.

5) Replacing the cont. rotation servos.

6) A CDS cell mounted on the front (I've read about using visible light to navigate

·· with using only a CDS cell and some LEDs... Maybe it'll work for lamps too)

7) Replacing the foamboard with expanded PVC.

8) Arms! What good is a robot without arms?! I just have no idea how I want them, or

·· what to make them out of.

9) Other stuff... I've got a lot of stamp pins and 2 general purpose output pins left...

·· What else should I put in?

10) A name. I would go with Ugly-bot but I don't want to insult Bill Chennault's awesome

··· Ugly Buster. I also would call it Junkbot, but there are tons of robots called that.

··· For now its working name is Johnny 0.5.

If anyone really has an intrest in circuit diagrams, code or more pictures, let me know

and I'll get them for you.

PS: Sorry for the long-winded description and huge pictures.

description:

To be honest I'm a little embarassed to present this robot.

Its about as ugly as they get... the wiring looks like spaghetti and

the components are either all spare junk or parts from various BOE-bot kits.

The original concept was a robotic "head" that sits on my desk so I can play

with AI and human interaction. It expanded into a hodge-podge robot with

several features.

To start, it uses two BOE-bot frames for its lower and upper body. There are

also two computer drive bay expanders to support the extended BOE platform.

On the BOE are a BS2 and a BS2 OEM that control the robot (Although I am toying

with the idea of adding a second BOE upside down under the existing one... but

I can't think why I'd need it).

The main focus is the robot's head. Its basically a pan and tilt turret with

sensors on it.

The two continuous rotation servos are attached to each other for the pan/tilt

movement, and the head its self is made out of foamboard (a non-conductive

foam core with paper on both sides used for arts and crafts).

The foamboard is a temp solution, I want to eventually replace it with expanded

PVC.

In the head is a homemade board that contains two IR leds (wired together), two

IR receivers, a 5-led array and a transistor-capacitor circuit that allows the

led array "mouth" to blink fast on - slow off with the center brightest so it

has a bit of a johnny-five "lip lights" effect.

Also in the head are a ping and a tilt switch device (ripped out of an Elmo toy)

that will eventually let me detect the angle of the tilt and prevent the robot

from wringing its own neck.

I haven't wired up the tilt switch yet as I'm hoping to replace the servos with

something a bit better soon, perhaps motors with encoders or stepper motors.

I'd like standard servos, but of course, they are kind of expensive.

On the front is a 2x16 LCD powered by Peter H. Anderson's #117 serial LCD backpack

on a custom board that takes advantage of all the backpack's features.

The backpack is located below the BS2OEM and connected via a homemade cable to

the LCD out front.

I also use two of the general purpose outputs of the #117 to power a simple

transistor circuit that switches on two 6volt lamps mounted on the bottom front

of the robot and act as headlights.

The whole thing will eventually be controlled by a simple AI that I'll get around

to making sometime after I replace the servos. For now its controlled by a homemade

matrix keypad connected to pins 0-7 on the BOE.

Future plans:

1) Writing the AI so I can get rid of the ugly matrix keypad.

2) IR remote control (again, so I can lose the matrix keypad).

3) Dual power sources to extend battery life (two 4x AA holders should work)

4) A top "headboard" that will let me control the ping, IR/mouth board and tilt

·· switch with just one wire coming off.

5) Replacing the cont. rotation servos.

6) A CDS cell mounted on the front (I've read about using visible light to navigate

·· with using only a CDS cell and some LEDs... Maybe it'll work for lamps too)

7) Replacing the foamboard with expanded PVC.

8) Arms! What good is a robot without arms?! I just have no idea how I want them, or

·· what to make them out of.

9) Other stuff... I've got a lot of stamp pins and 2 general purpose output pins left...

·· What else should I put in?

10) A name. I would go with Ugly-bot but I don't want to insult Bill Chennault's awesome

··· Ugly Buster. I also would call it Junkbot, but there are tons of robots called that.

··· For now its working name is Johnny 0.5.

If anyone really has an intrest in circuit diagrams, code or more pictures, let me know

and I'll get them for you.

PS: Sorry for the long-winded description and huge pictures.

Comments

Can the servos handle all that weight and still move the platform around well?

(Moderator -- maybe this should be moved to Completed Projects?)

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

When the going gets weird, the weird turn pro. -- HST

1uffakind.com/robots/povBitMapBuilder.php

1uffakind.com/robots/resistorLadder.php

The servos strain a little on carpet but do fine on hardwood. I was thinking about switching to VIN for them to make up for

the extra weight.

I made a few different boards for it to simply clean up the breadboard for other stuff. The head has a board with the IR and

LED mouth stuff on it, the chest has the headlight transistor circuit and sockets to plug in other stuff to the two remaining

#117 outputs (You can see the two green wires hanging out on the wiring photo). There's also the #117 board below the BS2

which was actually my first perf board project... it works fine but is about as ugly as I've ever seen (very poor planning).

The reason I didn't put this into the completed projects forum is because its... well... not completed.

I've been working on it around 8 months now and still have a LOT to do.

If you mods want to move it to completed projects, feel free to.

Thanks again for the praise Zoot [noparse]:)[/noparse]

Jax

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

If a robot has a screw then it must be romoved and hacked into..

The AI code will have to wait a while til I can fix the whole neck thing. I'm thinking of scrapping out some old printers I have

and try to get some stepper motors or motors with encoders that way. If I do... well then I'll start on the AI code soon.

It'll be a bit like a virtual pet kind of thing to enteract with the user. It won't need to be fed or anything like that, just interact

and maybe play a few games.

When your not actually interacting with it, it'll look around and try to "learn" things... such as where the walls are and the

like. (This is without it actually driving anywhere, just sitting on the desktop)

Have you heard of Kismat? That's what inspired my robot's concept, while Short Circuit inspired it's looks.

I would like schematics, code, pix, etc. I think that you have created something with a cute personality. It is neat. If you wish to email me, it is yhmmc@yahoo.com . Make sure that you say in the title it is about the robot or it may wind up in spam collection.

I absolutely LOVE AI. My dream is to make an intelligent machine. I also like Vampires, but that is another story.

Thanks!~

Post Edited (MovieMaker) : 12/5/2008 1:56:19 AM GMT

Ugha, Your AI program sounds pretty neat. Plus I'm a copier and printer repair tech, What printers do you have and I can tell you what you might be able to use out of them before you rip them apart. Might save you some time and trouble.

Jax

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

If a robot has a screw then it must be romoved and hacked into..

the two stepper motors inside run on 27 volts.

I have a couple more here, an Epson Stylus Color 740, a HP officejet v40 and a Cannon BJC 2100.

I believe the Hp and Cannon still work, so I don't want to rip them apart unless there's gold in dem der printers.

I know you didn't direct your question about AI to me Jax, but I've been a MUD (a text based multiplayer roleplaying game)

programmer for the past ten years, so I know a bit about AI programming... I'm hoping to move some of what I know into

the robot although I am seriously constrained by the BS2's memory space (Which is why I'm using multiple stamps).

Hey Jax... have you ever worked with C interfaces for stamp communication? I'm wanting to write a GUI for stamp projects

but I'm stumped by serial communication.

Moviemaker: My MUD is Vampire based [noparse]:)[/noparse]

If you don't mind, I'll post the info you asked for here instead of emailing you, that way anyone else with any intrest can

see as well (plus, someone might see a way to do something better or catch an error I made and give me a suggestion).

It'll take me a couple days for most of it.

I've attached the (extremely simple) Master and Slave codes for the robot. These both are just place holders until I can

work on the AI.

UPDATE: I had to switch my servos to VIN in order to prevent the second stamp from resetting when the robot moves

quickly. It must be too much of a current draw. The VIN change fixed it although it means I can't use 9volts anymore.

EDIT: I forgot to attach the file... All fixed now.

Post Edited (Ugha) : 12/5/2008 4:05:05 AM GMT

If you want to still use your 9v without resetting the stamps you must use opto-couplers to drive the motors or servos this will cut down on the current on the stamps and prevent them from resetting but you will need a new power supply for the mortors or servos for this and connect all grounds to the system ground of all the stamps as well.

I have not done any C in a long time but I can go back into my notes and books to find your answer to your communication problems if you want, It may take me about a week though so this is up to you, just let me know if I should do the research for you and post it here.

I'll download your files and check them out as I'm always looking for some good code for my folders, hehehe

Jax

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

If a robot has a screw then it must be romoved and hacked into..

humanoido

to increase the voltage, so I'm going to hold off on scrapping any more printers for stepper motors.

I did hear however, that there are some nice optos in some printers. Do you happen to know if any of those I mentioned

might have some? The one I scrapped before has two tiny IR slot interruptors that I intend on scrapping out (the only useful

parts in the whole printer that I found) but other than that, I saw nothing that may be an opto.

Additional power supply isn't a problem, the robot has a built in second battery pack under the BOE (just visible in the rear image)

in addition to the one under the bottom frame that most BOE-bots have.

Thanks for the offer on the C help, but I think I'll hold off on that project and focus more on my robot for now.

humanoido: Thanks for the praise... it means a lot [noparse]:)[/noparse]

I've followed your basic stamp super computer for a while, its a really amazing project... I'm just waiting for you to put some

wheels on that frame and make the whole thing into a robot!

Question for everyone... besides printers and floppy drives, does anyone know of any other good source to scrap out for

stepper motors?

Jax

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

If a robot has a screw then it must be romoved and hacked into..

I like the· look of your robot and it has a lot of· personality····(

Zoot

· (Moderator -- maybe this should be moved to Completed Projects?)

I second this

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

··Thanks for any·

·

·

·

·

Sam

Post Edited (sam_sam_sam) : 12/6/2008 5:55:22 PM GMT

I haven't really been able to do much AI. Back in the '80s, I did a little David Heiserman's Build your own self programming robot. And I worked with the RB5X robot that was built from this book. I have read about kismut and other robots. I have looked into the Elvinator project. But, I haven't been able to get EVERYTHING together at one time. I hope to take my two boebots and make them do AI. I have done all the stuff individually, but not all at once. I want it to get to the point were you mix A+B and get something totally different. I have a passion for it. I put the passion down in the 90's because I had about 12 robots and they had reached their technological limits. And ran sooo slow. I picked it up about six months ago because i figured now the technology is here. Now, if I can just manage to have enough cash, time, resources, etc. we shall see.

Ugha, thanks for your schematics, code, etc.

Thanks Guys!!

Post Edited (MovieMaker) : 12/6/2008 4:34:17 PM GMT

with that, hopefully it'll mean a much cleaner look for my poor ugly bot.

I'm going to toy with the slot interruptor I got off my scrapped printer... maybe I can find a way to make the robot detect

when the head has reached center so it can have some kind of base line to know its approx angle of rotation. This will

prevent it from doing an exorcist and spinning its head off.

I also want to give credit where credit is due. This robot would have been impossible without a great deal of help from

Sam_sam_sam. He gave me the ping, the BS2OEM, the transistors and almost all the perf board. Poor Johnny would

be about naked, deaf and blind without his help.

GWJax: This is a bit off topic, but I was looking at the power supply of the printer I scrapped, one output is 27 volts

and one is 5volts. Do you think this 5 volts would be regulated enough to safely use with a stamp? (I don't have an O-scope

to check).

MovieMaker: I'll try to get some schematics drawn up for you in a couple days.

Does anyone have any other ideas on ways I could improve this robot? I'm starting to draw a blank on what else to add.

Jax

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

If a robot has a screw then it must be romoved and hacked into..

I have a HP Desk Jet 656 c that i get ready to RETIRE --->>>· File 13

Dose it have a reusable part in it if so what are they

Thank You for any help that you can give me on this

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

··Thanks for any·

·

·

·

·

Sam

Jax

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

If a robot has a screw then it must be romoved and hacked into..

love it. You'd be famous on the forum [noparse];)[/noparse]

Basicly any type of electronic equipment is a gold mine for us electronic Geeks, If you see a TV or VCR or DVD unit on the side of the road for trash pick it up and strip it down for the electronics, motors, and really the IR rx modules. This is where I get alot of my stuff from but every once in a while I'll need something from Parallax hehehe a little plug for them! but anyways, grab everything electronic and rip it down for parts if the unit does not work or you just don't want it. Plus, remember the cases on the DVD, VRC player are great for cutting them down and making braces and bases for your bots too.

Jax

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

If a robot has a screw then it must be romoved and hacked into..

Thanks for all the compliments guys [noparse]:)[/noparse] Guess my ugly little bot was worth building after all.

I've been spending a lot of time working on arms for my robot... so far the prototypes are done (again, out of

foam board) but I've yet to create a motor controller board or overcome the same problem I always have...

how to keep the motors from going too far?

Encoders are expensive and switches won't work so I'm stumped at the moment.

I'll either figure it out, or post images soon asking for suggestions.

I also started the process of switching to TV remote control so now I don't have the ugly matrix keypad

plugged into the master stamp any longer. This frees up 8 pins so I've got plenty of room to play around

and add new features. (If I really wanted to, I could most likely go back to 1 stamp now... but I won't)

I finally spent a couple hours and got some schematics and pics of the face board (The IR and lip light board)

drawn up... take a look and feel free to ask any questions.

PS: Please forgive my crappy schematic-drawing and soldering skills.

Edit: I forgot to mention, I socketed the IR LEDs and the IR receivers in case I wanted to use them in another

project down the road.

Post Edited (Ugha) : 12/12/2008 10:57:41 PM GMT

Expect another update soon, I've just finished what I THINK will be a good layout for the arms... boy was that a pain.

I actually failed 8 attempts at the elbow joint and 14 attempts at the shoulder... that's a lot of disappointment lately and a lot of wasted time and material.

Building a robot with an absolute $0 budget is one of the biggest challenges of my life, but it does help me think outside the box.

I also received a tread and track kit for christmas which I'll be attaching to Johnny .5 soon.

Hope to post the update in the next couple days... wish me luck on my most recent arm contraption!

Jax

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

If a robot has a screw then it must be romoved and hacked into..

This past month I've spent (wasted) a great deal of time working on arm designs that don't work in the slightest.

My problem was simple... limited resources. I had·two continuous rotation servos and two cheap, low-powered tamiya motors and no

cash. So I struggled with different designs using the various junk I had around the house.

The elbow joint first...

My first attempt was a string pully using twined sowing thread wrapped around the motor shaft... needless to say it worked great the

first couple uses, then the string broke.

After a few varations of that, I tried a gear and belt system which failed cause superglue doesn't seem to work too well on rubber

belts salvaged from printers (had to shorten it).

Next was a gear system that failed because after 5+ hours of work, I realized I didn't have enough gears for both arms.

The second most successful design, was a screw-drive. Basically the motor drove a screw into a spacer glued to the forearm.

This worked pretty good except the whole thing was impossible to center correctly and it tended to shake a LOT and bind on

the extreme in and extreme out.

Various versions of the above were attempted until I finally came down to... well I'm not exactly sure what its called normally...

I call it a linkage.

I used a bit of metal from an old car windshield wiper and some scrap plastic to directly transfer the rotation to the forearm from

atop the shoulder. This causes the forearm to move perfectly every time to either fully raised or fully extended.

There are two problems with this design that I don't believe are critical enough to scrap everything and start again.

The first problem is that the motor reaches stall state at fully extended or raised. Since the motor moves so quickly I can only

apply power for a second or two and avoid overheating. I may also use PWM to reduce the strain on the motor if it has to hold

the raised state against gravity.

I'm also going to look into dynamic breaking, which i know next to nothing about, and see if it can force a motor to hold position

without straining it too much. (Any input would be nice)

The second problem is power. The motors are designed to be used with gear boxes so they have VERY little torque. I ended

up putting tactile switches on the forearms as "hands" and the weight of the wires coming off (24gauge stranded wire) originally

proved too much to allow the arm to bend at all so I replaced them with twisted pair pulled from Cat5e ethernet cable.

The twisted pair wire is much lighter, but still puts serious strain on the motors if the wire isn't at the exact right position.

I'm not sure what I'll do to solve this problem... most likely either live with it or replace the wire (again) with something smaller...

maybe some wire pulled out of an old mouse I have lying around.

Alright... on to the shoulder.

The shoulder was another test of patience. I went through MANY designs trying to figure out how to track the position of the

continuous rotation servos. I wanted to be able to have a somewhat closed loop system so I could angle the arm however I'd

like... this required some more creativity and many failed experiments.

First was what I called a "hole board". Basically a tactile switch on the arm that slid accross a board with holes in it, it could

count the amount of rotation based on how often the switch was released as it passed into a hole.

This put too much strain on the servo and also jammed cause of the tact switch getting "caught" in the holes.

I also considered using visible light LEDs and CDS cells to track the movement, but I don't have enough CDS cells to get the

full range needed... besides, wouldn't a robot look weird if his armpit glowed?

To sum up a bunch of other failed attempts... I ended up using gears from a printer and an old electric razor to build up a near-1:1

loop using encoders cut from an old mouse.

The servo horn has a carved-out gear hotglued to the bottom of it that turns another gear attached to a plate (hand-carved from

plastic from a printer case, which is why it looks lousy) that has the IR detector and LED pair hotglued in place to get a decent

reading off the·teeth in the gear.

Computer mice have actually two encoders in each pair that allow it to detect the direction of movement, this is called quadrature

encoding. Since the gears have triangle shaped teeth instead of slotted like the encoder disc in a mouse, this·almost impossible

to do in my application.

I won't really need it anyways as I can track the direction in software.

That's pretty much it.

I've attached pictures of the arm and shoulder I've made out of foam board. I'll eventually replace the motors with stronger ones

or come up with a better design, and replace the foam board with expanded PVC plastic.

Any recommendations about a better design or ways to avoid/fix my current problems would be greatly appreciated.

Post Edited (Ugha) : 1/20/2009 1:59:39 PM GMT

Jax

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

If a robot has a screw then it must be romoved and hacked into..

I ground down the tip of the hinge screw on the elbow and then fed that into the pot on the back side, problem was there was too much play. I only need a very small degree of motion

but either my screw-tip was too small or the pot had a little internal play, but there were several degrees of looseness where the resistance didn't change when I changed the angle

of the arm. I may end up re-attempting this when I get the expanded PVC... as it is, the foam board isn't secure enough to warrent another attempt.

I wanted to do something of the like for the shoulder joint as well, but I wasn't able to figure out how to hook it up without being in the way of the motor mounted to the top of the arm.

Hmm... I may try to use a pot in a gear system for the neck. I think I have just enough gears left for one more servo.. thanks for giving me the idea!

good luck on your research.

Jax

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

If a robot has a screw then it must be romoved and hacked into..

I've yet to wire up any of the electronics, so you'll notice a lack of any kind of microcontroller and wires sticking

out at all angles. I have, however, tested every element of the robot currently done and each part works as

far as I can test.

Now the changes...

First, I've replaced the lower boe-bot chassis with a Tamiya tank tread kit I got for christmas.

The kit came only with a single motor gearbox, but luckily I had bought the twin motor gearbox

years ago on a whim so it was easy to swap them out.

The tracks don't have enough space between them to place a BOE, and I don't have anything that I could possibly

use as replacement axles so I was forced to put a platform above the treads... this was actually an old zip-drive

cart holder I had lying around.

Unfortunately the tread kit was just a tad too small to properly extend from one end of the platform to the other,

so I added the extra links the kit came with and installed a makeshift axle-holder under the rear road wheel to

space things out a bit so it looks decent and has a tad more stability.

I decided that if I was going to use an upper platform design, I might as well get somewhat fancy and made it

so the whole thing could flip up to give me access to the batteries on the underside as well as the gearbox if

I ever needed to.

The top part is currently latched on by the back battery pack... which is held on by velcro. I intend to add

an additional latch of some kind in the future as I won't trust my bot to velcro alone.

Another change was the addition of arms, the arms should be fully functional, able to bend at both the elbow and

shoulder.

The arms have the above mentioned encoders on the shoulder joints (servo controlled) and motors with linkages

that raise and lower the forearm. I soldered up a small interface board on top of each shoulder to give a central

place for the wires to come from.

The "hands" are simply tactile switches with a bit of metal and foam board glued on. These will act as bumper

switches if the robot needs to move around... he'll stick his arms out and wander around like he's blind.

I also intend to write a "boxing" routine into him so he can detect something to the left or right then punch it

until the hand contacts.

The wires from the hands also go to the shoulder board and then from there it will go to a BS2.

I have three major problems I've yet to overcome with the robot.

First, and most important, is weight. The center of gravity is very far forward, causing the robot to tend to

fall forward upon stopping or too much movement of the arms. I added an additional battery pack to the back

hoping to counter that, but it only helped a little.

I may end up needing to add weights of some kind to the very rear. I had been trying to figure out something

"cool" I could add to the rear to actually make the weight useful, but I've yet to come up with anything

(suggestions are welcome).

The second problem is the strength of the arm motors. The motors were designed to be used with a gearbox,

and as such have very little torque on their own. They barely lift the arm as it is (the wires coming from the

hand switches have enough springiness to fight the motor's attempt to bend them)... when I switch to

expanded PVC instead of foam board, the added weight will make it impossible.

I have to figure out some other arm system to use down the road. I may get some tiny servos and attempt

to use those if my budget allows.

Another problem is the neck and head's pan and tilt system. It works ok, cept the head tries to spin off

or the tilt pops it off. I've avoided screwing anything together just to allow for this (I'd rather it pop off than

rip off). My solution is sometime soon saving up enough to get some servos to replace the current ones.

I attempted to use a gear and pot system but found I simply don't have the proper gears to do the job for

either servo. I also attempted to use a rotary encoder I salvaged from an old mouse, but that didn't work

either.

The head will simply have to wait until I can afford replacement servos... anyone want to buy some gently

used continuous rotation servos or trade them for some standard servos? Hehe.

Any thoughts or suggestions about my robot are welcome... heck, even insults are welcome. I insult him enough

myself, it wouldn't bother me to hear anyone else doing it [noparse]:)[/noparse]