Propeller P8X32A Datasheet Missing something ?

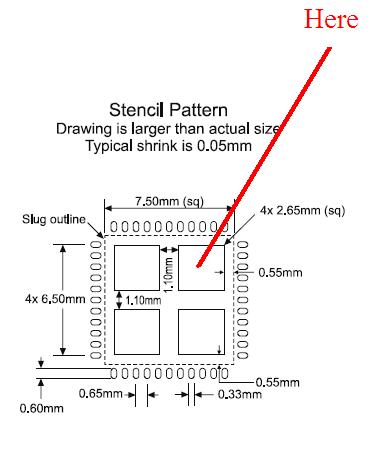

I am designing a circuit board and looking through the Propeller™ Data sheet I cant find any information that explains what the 4 square plugs are for on the 44-Pin QFN Chip. I called parallax tech-support but the gentleman stated "it was ground and was mentioned in the data sheet." Any ideas if this is correct? Picture is attached

Comments

Check out the following thread in the Sandbox section http://forums.parallax.com/showthread.php?p=755575·There are several comments regarding the requirements for mounting QFN chips.

Duffer

The picture you have shown is the recommended stencil pattern to use with the QFN package. The reason there are·multiple aperatures for the exposed slug is that it is a large surface area and filling the entire space would deposit too much paste for the slug which causes improper alignment and bridging between the slug and pins. The spacing between the aperatures allows·the excess solder paste to wick into the voids·and not migrate out to the pins where a short would cause a faulty soldering job.

In general, if you are not using a reflow process on your boards you should use the QFP package.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

Propeller Applications Engineer

Parallax, Inc.

Post Edited (Paul Baker (Parallax)) : 10/3/2008 9:31:37 PM GMT

Given that the Propeller is not a power hog, so doesn't dissipate much heat, that the QFP package needs no additional cooling, and that the QFN package has just as many Vss connections on its periphery, why is the bottom slug on the QFN package even necessary? Was it to avoid a custom QFN package design? Or is there more to it than that?

-Phil

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

'Still some PropSTICK Kit bare PCBs left!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

Propeller Applications Engineer

Parallax, Inc.

-Phil

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

'Still some PropSTICK Kit bare PCBs left!

Leon

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Amateur radio callsign: G1HSM

Suzuki SV1000S motorcycle

-Phil

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

'Still some PropSTICK Kit bare PCBs left!

Leon

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Amateur radio callsign: G1HSM

Suzuki SV1000S motorcycle

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Paul Baker

Propeller Applications Engineer

Parallax, Inc.

For My experiments I have 4 Big through holes to solder that chips.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Nothing is impossible, there are only different degrees of difficulty.

For every stupid question there is at least one intelligent answer.

Don't guess - ask instead.

If you don't ask you won't know.

If your gonna construct something, make it·as simple as·possible yet as versatile as posible.

Sapieha