More features suggestions for PWM product

A while back, someone did a post asking how to make a power PWM circuit for hydrogen production. I put in my two cents, and figured I'd go on ebay and see if anyone sells a simple thing. Wow. They do.

http://shop.ebay.com/?_from=R40&_trksid=m38&_nkw=PWM&_sacat=See-All-Categories

I'm just amazed at how much these things sell and the price! So, I figure I could make one better with all the bells and whistles. I've got some MOSFETs with a 0.0035mOhm Rds rated for 75 amps, although I know I won't get anywhere close. Most of these controllers have a fixed frequency, and adjustable duty and that's it. I'm making a list of features that I could add fairly easily and for hardly any money.

1. Adjustable Duty Cycle(obviously)

2. Adjustable Frequency(maybe for other inductive loads?)

3. An LCD screen that displays Duty and Freq.

4. A couple ADC's that measure voltage and current and display these as power, voltage, current on LCD

5. Four buttons to increase/decrease Freq. and Duty

6. Possibly use the ADC's to allow the user to set the desired current(Prop adjusts duty to output desired current)

7. Circuitry and all housed in a nice pretty enclosure($10)

8. ???

I'm sure the propeller can do all this stuff and more(very easily too!). Suggestions very welcome!

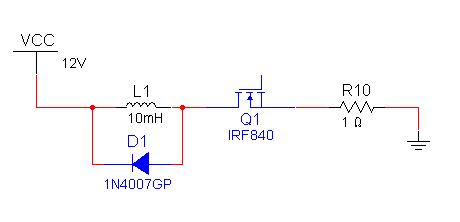

By the way, I've been thinking about how to maximize my MOSFETs. In particular, I'm using a driver chip for them, but I want to go a little further...·The initial transition from off to on dissipates almost half the power. In a steady full-on state, the mosfet barely gets warm at 20A. I figure that if I add an inductor right before the FET, and a diode in antiparallel with the indcutor, I can reduce the power dissipated in the mosfet by allowing a sort of delayed current flow as it turns on. However, when it turns off, the normal power would be dissipated, and the diode in antiparallel with the inductor would soak up most of the energy in it. Here's a schematic.

Anyway, I'm just looking to make a buck and the propeller seems perfect for all this. What do you think?

http://shop.ebay.com/?_from=R40&_trksid=m38&_nkw=PWM&_sacat=See-All-Categories

I'm just amazed at how much these things sell and the price! So, I figure I could make one better with all the bells and whistles. I've got some MOSFETs with a 0.0035mOhm Rds rated for 75 amps, although I know I won't get anywhere close. Most of these controllers have a fixed frequency, and adjustable duty and that's it. I'm making a list of features that I could add fairly easily and for hardly any money.

1. Adjustable Duty Cycle(obviously)

2. Adjustable Frequency(maybe for other inductive loads?)

3. An LCD screen that displays Duty and Freq.

4. A couple ADC's that measure voltage and current and display these as power, voltage, current on LCD

5. Four buttons to increase/decrease Freq. and Duty

6. Possibly use the ADC's to allow the user to set the desired current(Prop adjusts duty to output desired current)

7. Circuitry and all housed in a nice pretty enclosure($10)

8. ???

I'm sure the propeller can do all this stuff and more(very easily too!). Suggestions very welcome!

By the way, I've been thinking about how to maximize my MOSFETs. In particular, I'm using a driver chip for them, but I want to go a little further...·The initial transition from off to on dissipates almost half the power. In a steady full-on state, the mosfet barely gets warm at 20A. I figure that if I add an inductor right before the FET, and a diode in antiparallel with the indcutor, I can reduce the power dissipated in the mosfet by allowing a sort of delayed current flow as it turns on. However, when it turns off, the normal power would be dissipated, and the diode in antiparallel with the inductor would soak up most of the energy in it. Here's a schematic.

Anyway, I'm just looking to make a buck and the propeller seems perfect for all this. What do you think?

Comments

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

As for the oscillator... The resonant frequency of a circuit in those designs is up in the MHz range, yet so many of these garage expirements that claim to "have done it" use some arbitrary 20kHz(static) frequency. I'm not even suggesting that these people try to hit that sweet spot. The PWM is simply to provide a means of controlling current. If they want to do some expirements with pulsing·different frequencies through the water, hey, that's there thing. I just want to supply them with the means.

but we are about two weeks away from releasing our PWM board kit (high current load), Some of the features you talk about are included. Were running reliability tests right now, I have one sitting on a table switching 50 amps that has been running so far for 44 hours straight, with out a problem yet.( Woot....)

Adjustable PWM and Frequency (100hz- 100khz.) and duty (0-100%)

Pulse on Pulse configuration.

Fixed Duty cycle or closed loop current control.

50+ amps of switching power. With proper heat sinking and current limiting.

0-5v adjustable limit on off switch.

Oscilloscope display for configuration to a VGA monitor. ( With true triggering and frequency measurement)

Digitally stored values for constancy.

Full menu based configuration.

The cost currently is looking to be right at $200. If there is interest here as soon as I can get the online store up and running I can post the link, or Send me a PM for more information.

TJ

*edit* The price is a bit higher than ebay but its built to actually last, we have spent a lot of time developing a reliable product that wont nuke its self with in 5 min of use. We purchased a few of these "ebay" kits of varying designs, its quite funny to watch them melt when you try and use them anywhere near their limit.

Phil what duty are you running the mosfets at? To have them not generate much heat at 20 amps you got skills I need, Using twin 75 amp fet's anything over 30% we saw a rapid increase in temperature and associated failure.

Disclaimer.

I or any employee associated with this project can not be held responsible for the actions, damages or other harm from the use of this product.

Post Edited (TJHJ) : 8/6/2008 7:20:40 AM GMT

I've been thinking this over, and it seems that as you increase the frequency, there will be more switching cycles, leading to more heat being dissipated. It only seems logical that there should be some kind of derating of current vs. frequency. It seems the relationship SHOULD be linear since the relationship between switching cycles vs. energy dissipated is linear. I guess there is another feature... automatic frequency vs. current limitation calculations?

Is your project being done soley with the propeller, TJ?

A little off topic - I bought these FETS in a box of 800 for $50 on ebay. I sold about 700 of them for about a buck a piece and man I wish I hadn't... These things are absolutely amazing and haven't found anything that matches it since. Not even the IRF3205(110A, 55V). What FETs are you using TJHJ? And what driver? Mine is a sample from TI(like nearly every component I have for tinkering LOL)

IM using a logic level mosfet, but at 20 amps im having to dissipate alot more heat than you a bout 7 watts, not really that much but we saw a lot of early failures when there should have been no reason, after figuring out how to keep them cool they have maintained a nice reliable state. I ve got to find some of these E-bay fet's, lol.

The switching time for the fet I just did with trial and error until I got the relationship right, now all I hope is the next batch I order maintains that same spec.

Best of luck

1+ - $0.95

25+ - $0.85

100+ - $0.75

That pricing isn't bad... and the Rds(ON) is like 8mOhms.

I didn't hear how your projects went. Do you have them completed?