2-Liter Cola Bottle Rocket Launcher -funded by Arkansas Space Grant Consortium

I teach science at a small rural high school and one of our projects during the year is launching 2-liter cola bottles as rockets. The bottles are filled half way with water and then pressurized anywhere from 60 to 120 psi with air using a small compressor powered by my truck battery through the cigarette lighter source. It has been difficult to find a system of triggering the launch safely and remotely that would hold tension on the bottle so that pressures could be obtained that would send the rockets to satisfactory heights. I wrote a grant and was funded through the Arkansas Space Grant Consortium to build such a system. The results of my classes efforts are presented here. I am happy to say we achieved heights of 300 to 400 feet with the device.

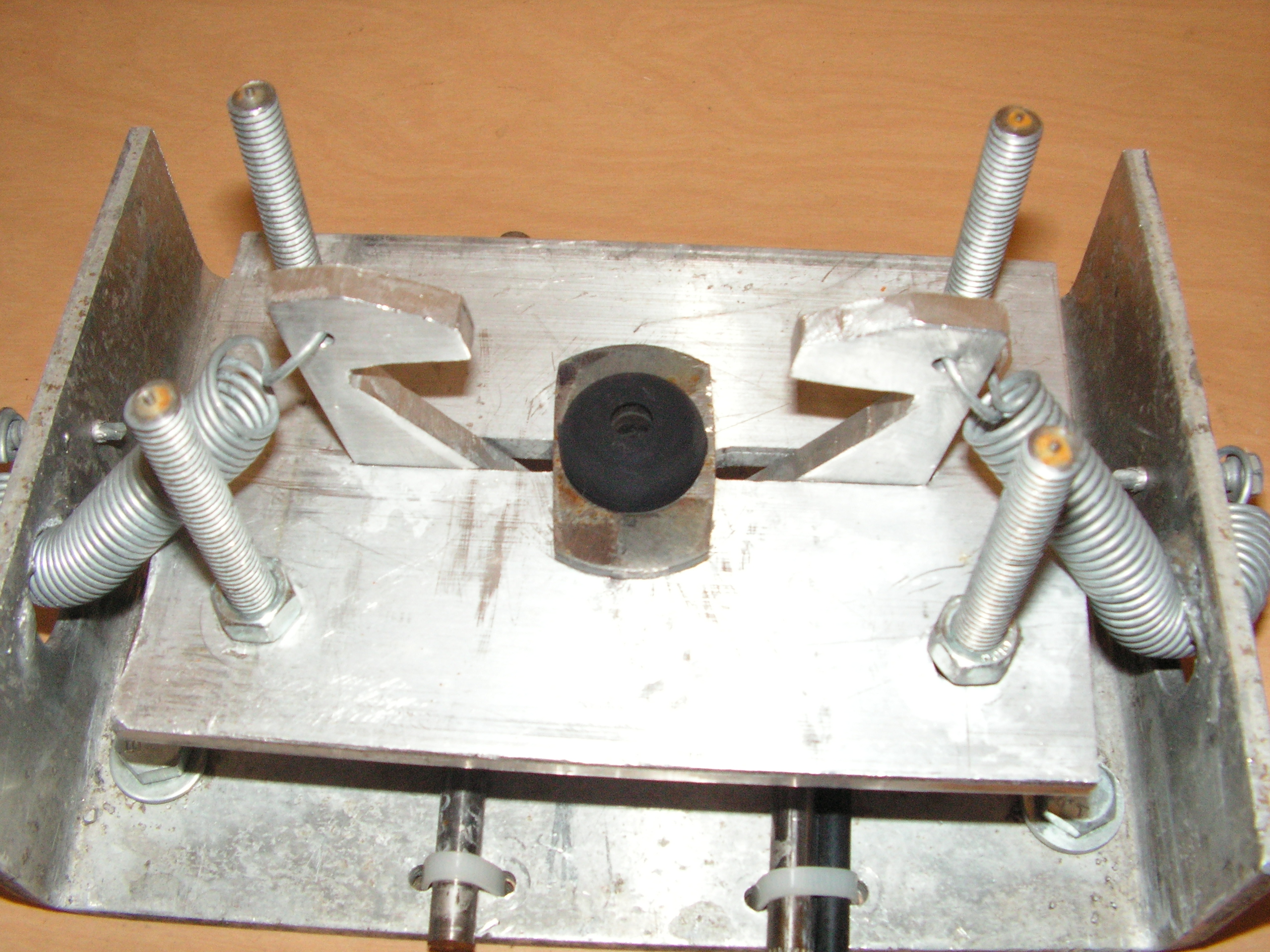

We first designed the mechanical system and built it and mounted it on an old table for stability. We then set about designing a circuit and the controller using the BS2 IC . With some help, we put together a PBasic program that would count down the ten seconds and display the launch status on the LCD. The features of the system include a manual override in case of pressure leak, automatic triggering of solenoid which releases the hold downs, and flashing LEDs and sound that indicate the status of the countdown. The whole thing is powered through an external 12 battery source which provides sufficient power to activate the solenoid to initiate the launch. I am attaching schematic, program code, and a Word document with drawings of mechanical parts of the launcher. As of this date, the launcher is using a wired system but future plans are to use the 433MHz transmitters and receivers available through Parallax to make the launcher into a wireless configuration. As a safety feature, an RFID system would be added to make sure no students were close to the rocket at the moment of launch. Each student would be wearing a RFID tag and the launcher would be programmed to abort if any student was near.

I am new at the schematic thing using ExpressSCH and I couldn't figure out how to upload it. I get an error message "cannot upload file MIME type:application/schdp/32." If someone can help me with that, I will upload the schematic. Feel free to contact me if you have any questions.

I think I got a .bmp of the schematic uploaded.

Scott Ausbrooks

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Showing up to school doesn't·mean you are a student any more than crawling up in an oven means that·you are a biscuit.

Post Edited (Cogburn) : 6/10/2008 5:46:15 PM GMT

We first designed the mechanical system and built it and mounted it on an old table for stability. We then set about designing a circuit and the controller using the BS2 IC . With some help, we put together a PBasic program that would count down the ten seconds and display the launch status on the LCD. The features of the system include a manual override in case of pressure leak, automatic triggering of solenoid which releases the hold downs, and flashing LEDs and sound that indicate the status of the countdown. The whole thing is powered through an external 12 battery source which provides sufficient power to activate the solenoid to initiate the launch. I am attaching schematic, program code, and a Word document with drawings of mechanical parts of the launcher. As of this date, the launcher is using a wired system but future plans are to use the 433MHz transmitters and receivers available through Parallax to make the launcher into a wireless configuration. As a safety feature, an RFID system would be added to make sure no students were close to the rocket at the moment of launch. Each student would be wearing a RFID tag and the launcher would be programmed to abort if any student was near.

I am new at the schematic thing using ExpressSCH and I couldn't figure out how to upload it. I get an error message "cannot upload file MIME type:application/schdp/32." If someone can help me with that, I will upload the schematic. Feel free to contact me if you have any questions.

I think I got a .bmp of the schematic uploaded.

Scott Ausbrooks

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Showing up to school doesn't·mean you are a student any more than crawling up in an oven means that·you are a biscuit.

Post Edited (Cogburn) : 6/10/2008 5:46:15 PM GMT

Comments

Also, you'd really want to know if anyone --not just students-- were "within range" of a pressurized bottle that could explode or veer off course. Putting enough RFID tags on enough people (all people), and keeping all those·tagged people clustered near to the RFID reader(s)(which would·itself/themselves·be located distant from the·rocket)·may be too demanding; some other method of scanning/surveying the "danger zone" around the pressurized bottle would probably make for a safer system --maybe realtime video being monitored by a person?

120 psi in those bottles sounds a bit close to the dangerous end of their capacity to reliably/safely be pressurized ?

PAR

The large Ford valve stem is just the right size to accept the mouth of the bottle. The hold downs clamp on the rim that is on the neck of the bottle. This seal is enough to hold the 120 PSI. I will try to draw a more detailed diagram of the valve stem/bottle mouth and post it here.

The students are well monitored, safety is stressed before, during, and after launching. I have had no accidents involving a launch yet.

The water under pressure provides the thrust. The product of the mass * velocity for the water being ejected out the mouth of the bottle will, theoretically, equal the rocket's mass * its velocity. Accelerations using this system are unbelievably high.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

PLEASE CONSIDER the following:

Do you want a quickly operational black box solution or the knowledge included therein?······

Does the control system monitor pressure? It could possible log pressures of each launch. You could also set it up to get to a certain pressure and then launch.

The RFID tag monitoring idea...ummm...I think there needs to be something better. You want to protect the launch zone from anyone being there - tag or not as PAR pointed out. There are different ways to do this electronically, but it sounds like procedurally you are covered. Good job looking out for the safety.

Have you placed payloads on the rockets? What modifications do you do to the bottles to make them fly?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter

www.brilldea.com·- uOLED-IOC, RGB LEDs, TLC5940 driver PCB

www.tdswieter.com

One little spark of imagination is all it takes for an idea to explode

The system does not monitor pressure. Pressure is monitored at the source. The compressor has a pressure gauge and the countdown is begun when the pressure reaches a certain level. Usually 90 to 100 PSI.

We use astrolabes and trigonometry to calculate height manually. I then take the students through a process of writing a calculator program that will do the calculations for them and it will even draw a facsimile of the path of the rocket on the screen as an animated graphic. The program treats the rocket ballistically which is not really the case but it superimposes the path on the triangle created by the astrolabe measurements from upwind and downwind angle data. The kids like the animation.

We modify the bottles with duct tape and some fin material(usually cardboard or foamboard) and we make a nosecone out of another 2-liter bottle cut off about half way down. This is taped on top of the intact bottle and acts somewhat like a nosecone. It leaves an empty chamber in the top to place the egg later in the activity. There are many internet sites where the rocket design is depicted. No modification is necessary actually and you could launch a bottle without any mods and without water. Watch out though- the flight path is unpredictable without fins. Without water, the height is very limited as the water mass provides the thrust along with its velocity.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Showing up to school doesn't·mean you are a student any more than crawling up in an oven means that·you are a biscuit.

Post Edited (Cogburn) : 6/14/2008 4:56:18 PM GMT

PAR

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Showing up to school doesn't·mean you are a student any more than crawling up in an oven means that·you are a biscuit.

temp VAR Byte

I must have erased it when cleaning the code up

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Showing up to school doesn't·mean you are a student any more than crawling up in an oven means that·you are a biscuit.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Showing up to school doesn't·mean you are a student any more than crawling up in an oven means that·you are a biscuit.

You did a really good job with this and even better that you and students learned in the process!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter

www.brilldea.com·- uOLED-IOC, RGB LEDs, TLC5940 driver PCB

www.tdswieter.com

One little spark of imagination is all it takes for an idea to explode