10 Amp Smart Solar Battery Charger - Going Green?

Beau Schwabe

Posts: 6,576

Beau Schwabe

Posts: 6,576

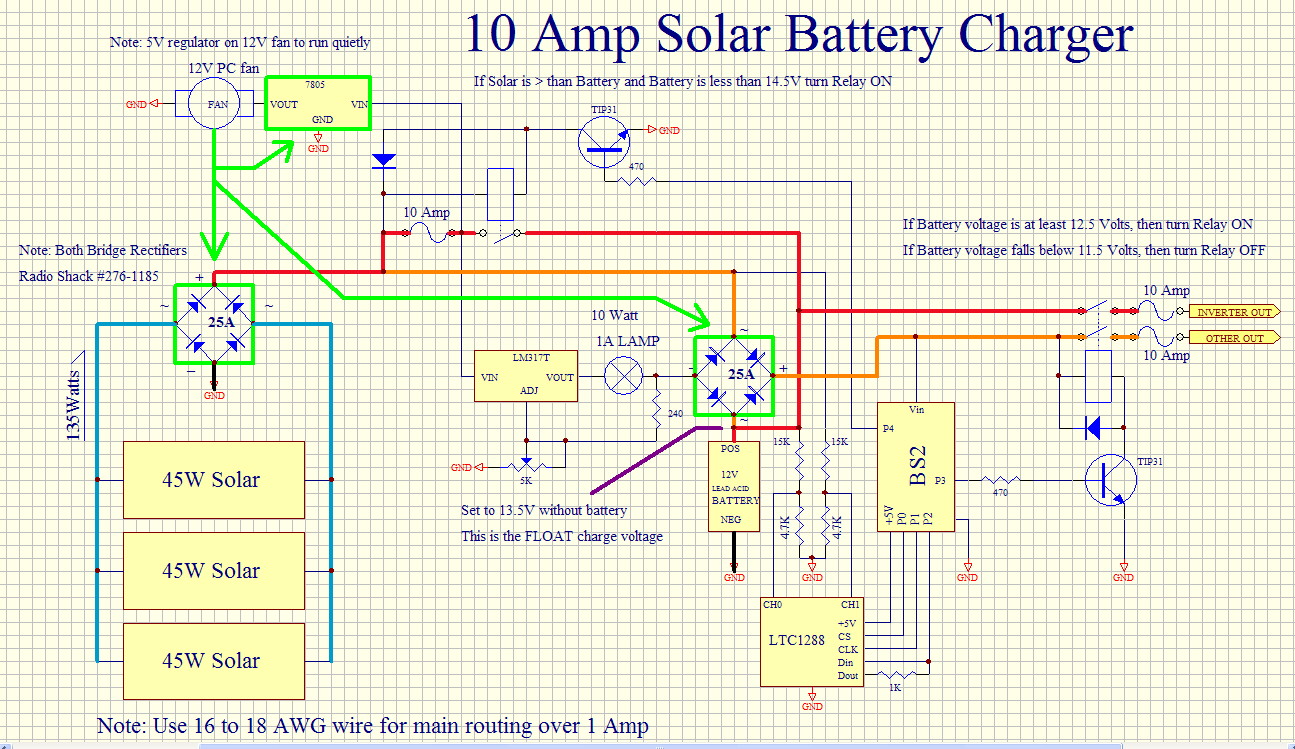

As gas prices soar, the subject of solar power, wind power, and other alternative energies will become more and more popular. My initial goal was to move my home office off-grid and expand from there. I'm not quite there yet, but probably about 75% of the way. Here is a design that I have been using for almost a year now. With careful consideration, I think the idea could easily be scaled up or down depending on your needs.

Enjoy!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

Post Edited (Beau Schwabe (Parallax)) : 5/19/2008 7:16:39 AM GMT

Enjoy!

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

Post Edited (Beau Schwabe (Parallax)) : 5/19/2008 7:16:39 AM GMT

Comments

Nice charger design.

There was·a guy on eBay selling pwbs with a BS2 and an ADC 0838 of which only two channels were used. This pwb would be a perfect foundation to build your charger around. I bought two of them and put them aside until a need like this.

Regards,

TCIII

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

If you are going to send·a Robot·to save the world, you·better make sure it likes it the way it is!

Thank You for sharing this with us

I have to ask this

Why do you have two bridge rectifiers there I understand the one next to the solar panel but the one by the· Basic Stamp· can you tell why that one is there

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

··Thanks for any·

·

·

·

·

Sam

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Max Wooden

Reedley, California

I got my panels from E-Bay for about $4 per Watt. Unless you have extreme patience, I would not try to build my own panels (Been there done that)... Even though I got what I thought was an extremely good deal on individual solar cells they are very fragile and break easily. I was lucky to get about a 50% yield. .... Instead I would search for panels that are already constructed, so that all you need to do is connect the wires and go.

An interesting note: We recently modified our homeowners insurance, and asked about Solar Panels. When they are "attached" to your roof, they are considered part of your home, and are thus insured 100% as part of your roof. If any weather-related event were to damage them they would be replaced.

The LTC1298 that we sell should also work just fine, in fact I stole the code from that to talk to the LTC1288... The LTC1288 is really just what I happened to already have on hand.

http://www.parallax.com/Store/Microcontrollers/BASICStampModules/tabid/134/txtSearch/LTC/List/1/ProductID/232/Default.aspx?SortField=ProductName,ProductName

... But to answer your question.... "how many .55 volt 2amp solar cells would you need to make the panel for this?" typically 12V panels are constructed with 36 Cells ... giving an unloaded voltage of about 20V

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

Post Edited (Beau Schwabe (Parallax)) : 5/19/2008 8:13:09 PM GMT

its a odd one I got off ebay a year ago. its a OEM model supposedly..

i-Stamp2p

BASIC Stamp2p

OEM board

Copyright 2002 by innovative experiment

it looks like a huge basic stamp 2p40

has a socketed rs232 converter, and socketed eprom. and has the same pinout as the 2p40 cept for the one pin.

pin 40 (vin) is not connected to a regulator, or anything for that matter.. [noparse]:)[/noparse]

but otherwise its very nice. and works perfectly fine with the pbasic [noparse]:)[/noparse]

What was the need for a 12 bit ADC?

If you are only dealing in tenths of a volt, why the need for such high accuracy?

Am I missing something here?

Regards,

TCIII

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

If you are going to send·a Robot·to save the world, you·better make sure it likes it the way it is!

"What was the need for a 12 bit ADC?" - No need, I didn't see the point in buying an 8-bit ADC when I already had an extra 12-bit ADC from another project.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

Cool project. Thinking of something similar - i've got 3 panels off a UK sale (Maplins) to charge 12v batteries.

Free battery charging!

James

How about IRLZ44 mosfet to replace the relays?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

www.fd.com.my

www.mercedes.com.my

You could use the IRLZ44... When I first put this together I had four car batteries in parallel. I wanted to use relays to make sure something wouldn't

go terribly wrong with silicon and I could visually debug the switch (relay) position. It worked well enough with the relays, that I just didn't bother with

using a solid state version of the relay.

Besides, this was a learning experience... One could easily go on Ebay and order a 120Watt (12V 10A) solar charge controller to do basically the same thing.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

If not, the charge seems to leak through the mosfet when the panel voltage is 4 volts higher than the battery voltage.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

www.fd.com.my

www.mercedes.com.my

It so happens that I have a similar design running now but am having problems finding a proper mosfet to use. I am using an n-channel but I need a p-channel that has similar Vds curves as the IRLZ44.

I have looked at Digi-Key and IR but have not found one. Any suggestions for a logic level, p-channel, type mosfet?

Thanks for any input,

Dave

Why can't you use n-channel mosfets? I am using n-channel mosfets now, but need an optocoupler.

Beau,

What's the size of the car batteries you use? NS70? Do you really need 4 of them for your 3 small panels?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

www.fd.com.my

www.mercedes.com.my

I wanted to design a system that would work as a 1 kW UPS for at least 2 and a half hours without taking the battery supply too far out of the normal voltage range. Four car batteries would do just that. I just used standard Wal-Mart brand 750 Cranking amp car batteries. I think I paid about $45 for each of them and it would have been cheaper if I had a core to turn in, but because it was essentially for a "new" application, I paid a $9 core fee for the battery. The 3 small panels in the schematic were part of an earlier design that is suitable for a single car battery.

As I expand, one pass across the top of my roof line will hold about 540 Watts worth of solar Panels (45 Amps), I also plan to complement this with a 500 Watt Wind generator.... So on a "good day" I could potentially see about 1kW. This will tie into a 100 Amp Panel box and either provide a grid tie with the existing mains or provide a switched supplementary supply to the house depending on the demand.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

What is a "core"?

I am concerned about the 2 bridge rectifiers in your circuit.

That would drop the voltage by 4 diode drops at 10 amps ( 4 volts? ).

Plus the drop at the fuse, it would weaken the charging current considerably.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

www.fd.com.my

www.mercedes.com.my

·

The "core" is the used battery... in the US, a recycling fee is implemented on tires and batteries.· If you can produce a "core" during a purchase or within 30 days after a purchase the fee is waived.· Otherwise you are required to pay an additional amount.

·

I think that the Bridge rectifiers are fine... they are rated for more than twice the current capacity, and there is only a 2 diode drop under the high current charge, and the fuses that I am using are actually resetable·panel mount breakers.· The other bridge "sees" an additional 2 diode drops, but this is under·float charge conditions and is current limited to 1 Amp.

·

When in use, the inverter never sees a diode drop and is looking directly at the battery through a 10 Amp panel breaker.· The auxiliary or "other" output power only sees 1 diode drop to the Battery, and 3 diode drops to the solar panels.· The auxiliary·is meant for lighter loads or DC powered applications.· The Panels are composed of·36 cells each producing an unloaded voltage of about·19.8 Volts (.55V per cell) ... even with a 4-diode drop (2.4V)·there is·enough overhead (17.4V) to reach a more than adequate charging voltage for the Lead Acid batteries.

·

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

When the charging current is more than 5 amps, each diode drop is much more than 0.7 volts.

On top of that, there is a drop due to the copper wires from the panel to the batteries, which is substantial when the current is 10 amps.

Most commercial solar panels already have a built-in diode.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

www.fd.com.my

www.mercedes.com.my

I will post this as a new topic in the SANDBOX.

Dave

Post Edited (Dave E) : 6/5/2008 1:48:55 AM GMT

·

"...if you used an opamp/comparator/Schmidt to give you..." ... Yeah, I could have even eliminated using a Stamp altogether with a couple of comparators and some glue logic, but then I wouldn't be able to post it as a completed project.· The software version of a comparator works just fine for this project and allows for easy adjustments.

·

I'm waiting on a few things to ship from Hong Kong·that I will add as a continuation of this project ... we'll see how that goes.

·

·

William,

I'm not too concerned about voltage drop across the wires from the solar panels.· In the final project, I will be using 1/4 inch copper tubing·to route power between the cells, and then deliver·power directly to·the charge controller with wire rated for·100 Amps. (<-more than twice the rating the cells will be able to provide which is about 45 Amps)

·

I agree, the diode voltage drop is directly related to temperature and it will increase with more applied current as a result of generated heat across the PN junction.· This is partially the·reason for a cooling fan in close proximity to the rectifier(s)·so that the temperature can be·lowered.

·

That said there is no failure mechanism for the fan... I should probably add·temperature sensors to monitor the bridge rectifiers to be more complete and since the Lead Acid·chemistry is affected by temperature, it would be a good idea to monitor the ambient temperature near the batteries also.

···

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

Post Edited (Beau Schwabe (Parallax)) : 6/5/2008 5:50:26 AM GMT

I would feel better if you get rid of the bridge rectifiers....., but nvm.

BTW,

1. How do you measure the charging current?

2. Are you sure the typical AC resettable fuse switch can work with DC?

3. Are the copper pipes from your panel to the charge controller hollow?

4. How many percent of the panels' total rated current are you able to achieve at noon?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

www.fd.com.my

www.mercedes.com.my

1) I have a Fluke meter that will measure up to 25A

2) Yes

3) The hollow copper tubes (total cross sectional area is .0368 inches capable of handling at least 60 Amps) are only connected to the panels spanning a total of 36 linear feet ; the wiring from the copper tubing to the controller bisects the tubing at 18 feet ( about a 4 m Ohm loss from the farthest panel) and travels about 50 feet to the charge controller. This wire is standard 2 gauge UL approved. .... total resistance between the farthest panel and the charge controller is about 12 m Ohm

4) I will get back to you on that... we've had a few overcast days lately. The panels I have are amorphous as opposed to crystalline and because of that, they work better under lower lighting conditions. Even during an overcast day I can get about 15-20% of the rated power.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Beau Schwabe

IC Layout Engineer

Parallax, Inc.

Post Edited (Beau Schwabe (Parallax)) : 6/6/2008 4:04:13 AM GMT