Need advice for board to wire connector

Timothy D. Swieter

Posts: 1,613

Timothy D. Swieter

Posts: 1,613

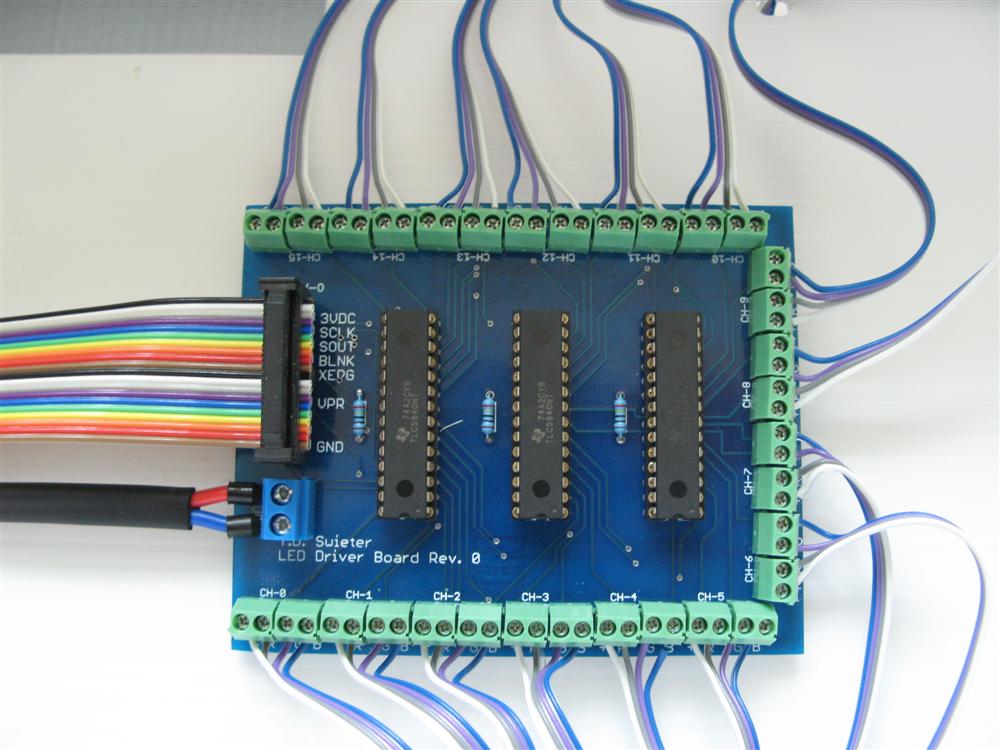

I am redesigning the 16 Channel LED Driver board that I created at the end of last year.· I attached a picture of the original design with components populated.

I am looking to change the green terminal blocks out for something better.· The terminal blocks are OK, but they take up a lot of space and I can't design a larger board (Eagle version limitation).· I would like to have all eight channels on a side of the board instead of wrapping around to another edge.· Also, if I wanted to disconnect all the LEDs (the LEDs are wired to the green terminal block) it is not a quick process.· As·each TB has to be unscrewed with a tiny screw driver.·

What I would like is to replace the terminal blocks with a 0.1" right angle header, single row, four positions.· I need advice on a mating connector for this though.· There are many around, but my head is spinning from browsing Digikey and Tyco Electronics catalog.· Ideally the connector is inexpensive (<US$0.50 in qty. of 100) and doesn't require expensive tooling either.· It would be great if there was some simple insulation displacement type of connector wire I can lay in the four·conductors and snap it close.· No crimping, no striping.

What·have you guys used?· Any recommendations for a connector to connect to a right angle, 0.1" space header?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter

www.brilldea.com·- check out the uOLED-IOC, an I/O expansion for the uOLED-96-PROP

www.tdswieter.com

One little spark of imagination is all it takes for an idea to explode

I am looking to change the green terminal blocks out for something better.· The terminal blocks are OK, but they take up a lot of space and I can't design a larger board (Eagle version limitation).· I would like to have all eight channels on a side of the board instead of wrapping around to another edge.· Also, if I wanted to disconnect all the LEDs (the LEDs are wired to the green terminal block) it is not a quick process.· As·each TB has to be unscrewed with a tiny screw driver.·

What I would like is to replace the terminal blocks with a 0.1" right angle header, single row, four positions.· I need advice on a mating connector for this though.· There are many around, but my head is spinning from browsing Digikey and Tyco Electronics catalog.· Ideally the connector is inexpensive (<US$0.50 in qty. of 100) and doesn't require expensive tooling either.· It would be great if there was some simple insulation displacement type of connector wire I can lay in the four·conductors and snap it close.· No crimping, no striping.

What·have you guys used?· Any recommendations for a connector to connect to a right angle, 0.1" space header?

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter

www.brilldea.com·- check out the uOLED-IOC, an I/O expansion for the uOLED-96-PROP

www.tdswieter.com

One little spark of imagination is all it takes for an idea to explode

Comments

Leon

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Amateur radio callsign: G1HSM

Suzuki SV1000S motorcycle

I have a couple goals of the new design. One goal is the ability to connect and disconnect the LED easily for servicing the board or LEDs if needed. Another goal is to make the board still appeal to hobbyist and home brew applications. I could go with some fancy connector, but it would be costly and the hobbyist may shy away from the board.

I found a knock off connector similar to the Mokex KK here in HK. It is a simple0.1" space, four position connector - common. It would work, but the crimping would not be fun. I am redesigning the board for a project that will use nine assemblies. 16 Ch./pcb * 4 crimps/ch * 9 pcb = 576 crimp contacts (assuming no recrimping

From a hobbyist perspective, do you think 0.1", 4 position header is good idea? I do, as there are many varitions on this header. The downside is all the crimping for the parts I want to use, I am sure there are IDC connectors for this somewhere. Another option I am considering is a high pin count, say a 2x24, 0.1" space header and a matching insulation displacement connector. I would then use ribbon cable to each LED cluster. The advantage of this design is it is inexpensive to buy the parts, it is quick to assemble. Really easy to disconnect all LEDs. I think a downside is that the hobbyist may shy away from the connector topology.

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Timothy D. Swieter

www.brilldea.com·- check out the uOLED-IOC, an I/O expansion for the uOLED-96-PROP

www.tdswieter.com

One little spark of imagination is all it takes for an idea to explode

IDC connectors will look neater as they are two row. Making them up is very quick with the correct tool, which isn't expensive.

Another option is multiplexing the signals, which will save a lot of connectors, but will need some additional hardware.

Leon

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

Amateur radio callsign: G1HSM

Suzuki SV1000S motorcycle

▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔▔

~~ dRu ~~