High frequency Stepper Motor driving

Mickster

Posts: 2,904

Mickster

Posts: 2,904

in Propeller 2

How would we handle this on the P2, is there a smartpin mode that would suit?

Craig

Comments

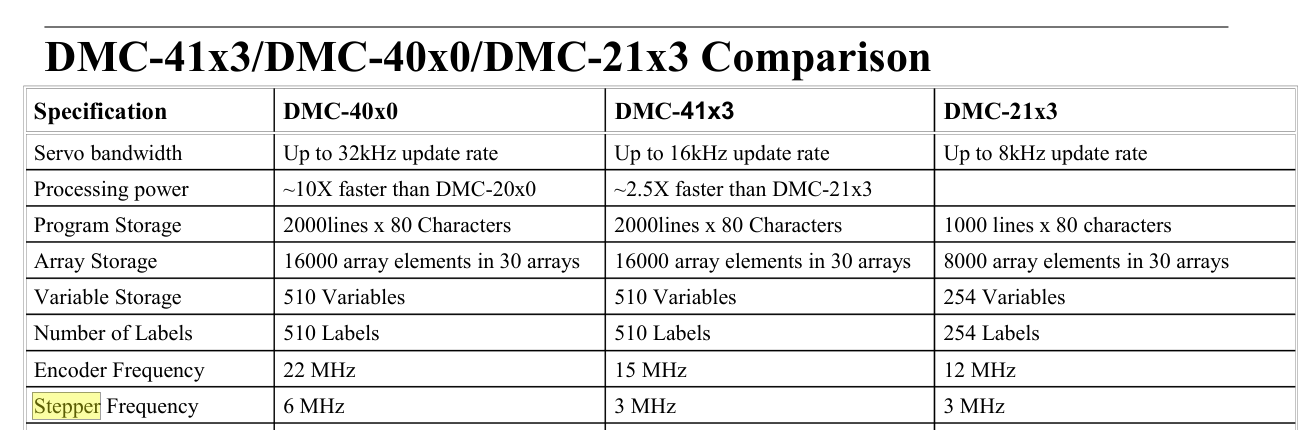

Not totally following you here. The DMC controller is able to control X number of servos or stepper motors up to 6 million steps per second.

The P2 can output pulses at that rate but needs a driver board to handle the motors.

A smartpin would really not be needed here as you want to control these motors by outputting a number of pulses at a set or scaled frequency to do precise movements.

There is a smartpin mode to control servos that are driven by a frequency though.

Mike

Oh, this is understood. I am only interested in generating the pulse/direction signals.

I have never driven a stepper because I am more of a closed-loop servo guy and so my initial thoughts are:

I already have the velocity profiler/trajectory generator which runs @500Hz, the output of which feeds the PID and the PID is responsible for commanding the BLM or whatever. For a stepper, I imagine dumping X number stepper pulses in a register and specifying the rate at which they are sent to the stepper driver. Or am I overcomplicating this?

Craig

%00100 = pulse/cycle output

this smartpin mode should work

output N pulses at X frequency and then stop

if your control loop runs at 500 Hz, you have a 2 milliseconds frame that each of the axe's smart pins should fill with steps. it is unlikely that it fills this 2 ms frame exactly, it will always have to wait a little. this will lead to jittering if not cared for.

Excellent! Many thanks and yes, I expect that some form of buffering might be required. If the smartpin can be used, I'll make it work.

P2: The answer is "yes", now, what's the question?

Craig

I control a stepper in my robot. It extends or hides the arm with lamps. No advanced stuff there at all As it does its job at needed speed, I didn't even try to play with smartpins or asm. Waitus() amount was determined experimentally to make the arm open at desired speed.

As it does its job at needed speed, I didn't even try to play with smartpins or asm. Waitus() amount was determined experimentally to make the arm open at desired speed.

If you do want to try the smart pin route, it's pretty easy.

This sets up a pin to output pulses.

To generate pulses on a smart pin (with option to wait for conclusion of pulses).

pub pulses_out(pin, count, hold) pinfloat(pin) ' reset wypin(pin, count) ' set new count pinlow(pin) ' start pulses if (hold) repeat until pinr(pin) ' let pulses finishThe only positive experience I ever had with steppers is that they put me in business

A huge machine destined for General motors had 3 huge stepper motor axes. Positioning was all over the place.

I was called in to investigate and told them that they needed to throw away this open loop garbage and stick some closed-loop servos on there. They hired me to make it happen and gave me carte blanche.

It was a success and they decided that they wanted a bunch more of these machines, provided that I developed the controls. Instant profitable business

I will never accept an open loop solution, no matter what

Craig

@JonnyMac

Many thanks Jon...heck, the Props never fail to put a smile on my face

Craig