Planar Inductor Questions

I am working on some boards for this inductive switch product that Tony recommended.

http://www.ti.com/lit/ds/symlink/ldc0851.pdf

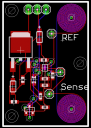

After including the 3v3 LDO and other parts, the board is getting a bit large to fit in tight spaces. I am wondering if anyone has any experience with this to know how badly it would affect the performance to break this up into 2 or 3 boards.

1. Main components with Regulator, IC, caps, etc.

2. Ref planar inductor

3. Sense planar inductor

If I use the same length wire( ie 2") for both the sense and ref coils, would this screw up the performance? It would nice to be able to break this up and park the main board slightly away from the parts to detect. I could get by with having the sense and ref on the same board, similar to how this is shown now, just divide the board in half with jumpers. These are 10mm diameter coils just like the examples in the PDF. The distance for detection should be less than the diameter.

I think I will not be using a reference metal for distance setting for the trigger, but rather the other mode where you can set the threshold with a resistor. I think it does not matter which side of the coil is used for detection of the metal.

http://www.ti.com/lit/ds/symlink/ldc0851.pdf

After including the 3v3 LDO and other parts, the board is getting a bit large to fit in tight spaces. I am wondering if anyone has any experience with this to know how badly it would affect the performance to break this up into 2 or 3 boards.

1. Main components with Regulator, IC, caps, etc.

2. Ref planar inductor

3. Sense planar inductor

If I use the same length wire( ie 2") for both the sense and ref coils, would this screw up the performance? It would nice to be able to break this up and park the main board slightly away from the parts to detect. I could get by with having the sense and ref on the same board, similar to how this is shown now, just divide the board in half with jumpers. These are 10mm diameter coils just like the examples in the PDF. The distance for detection should be less than the diameter.

I think I will not be using a reference metal for distance setting for the trigger, but rather the other mode where you can set the threshold with a resistor. I think it does not matter which side of the coil is used for detection of the metal.

Comments

There are also the more costly LDC1000 or LDC1101. They kick out quantitative values for L and Rp of a single coil, which you could use to measure how far the dead bolt has traveled. µP required though.

At the other extreme, it might work with a simple metal detector, like this one...

http://www.micro-examples.com/articles/index.php/PicoDetector

Reason I ask, is that I have been working on a pinpoint metal detector, and I'm using 100uH chip inductors and they seem to work great. It looks like with the IC you are using that the chip inductors would work as well and allow you to balance any component tolerances through the ADJ pin.

Video test of my pin-point metal detector using the chip inductors:

Yes, we have used chip inductors for magnet sense, and they worked well.

For detect of the wings on the dead-latch, maybe something vertically aligned, like this ?

Note: On Inductors, an air core might be better suited than an inductor with a metallic core. A metallic core will limit overall sensitivity due to saturation issues.

https://e2e.ti.com/support/sensor/inductive-sensing/

ie it may like some parasitic C, to pull frequencies down, but not so much coupling that a lossy dielectric affects Q ?

...It's not so much lower inductance that gives better results, it has to do with the permeability of a metallic core. in the absence of metal with the exception of the wire in the coil itself, less metal will provide a more dynamic response when there actually is metal present you are trying to detect.

I think that there are slight differences between each coil that you are able to tune or detune by adding or subtracting parasitic capacitance <-- IOW, you are able to hold your tongue just right in this experiment.

I'm not sure exactly how the TI chip works, but I have an idea, since it uses a common cap, and it has subtile hints in the block diagram and similar to what I was doing in the video.

First imagine pushing one person in a swing at just the right interval or resonant frequency. you apply minimal force to maintain the oscillations. Now imagine pushing that same person but on every other interval. It still takes little force to maintain the oscillations. Now add another person on a swing. Keeping the same pace as the every other interval now you push one person, and then the next, alternating between the two. Both people in the swing however are synchronized and swinging together. Now substitute the people swinging for coils. Any perturbation on one coil or the other will cause an imbalance that will show up on the output.

Note: It looks like your tilting adjustments could be accomplished by adjusting the "balance" electrically using the ADJ pin on the IC... it looks like though that the symbol is drawn wrong for the 4-bit-ADC in that it should be facing inward, as I "think" this provides a bias to adjust for any coil/layout/environment discrepancies