Motors, Batteries, and Chains

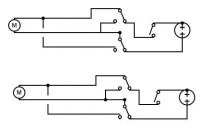

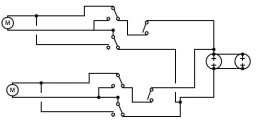

OK so I stripped two motors and batteries out of some rechargeable drills. The first diagram is my current set up. It works fine when the wheels aren't on the ground. The motors are connected to a chain drive that increases the torque and reduces the speed. If I put it on the ground the chain immediately jumps of the motor sprocket. I was thing that if I put the batteries in a parallel configuration that runs both motors This might help the problem. I think it would reduce the speed but even if I cut the speed in half I'd be OK. Maybe not so much with the reduced torque but I'll have to try it to know. I'm concerned about recharging the batteries in this parallel configuration and also not even sure this will do anything for me. Any ideas or suggestions that don't cost more money??? The last diagram cut off the motors and one battery when I uploaded it but hopefully you can see the idea.

Comments

When drawing SPDT switches in a diagram, the three points of the switch form an acute triangle. The point furthest away from from the other two points is usually the common lead. The way you have it drawn threw me off at first. If a DPDT switch then a light dashed line is drawn between the two "swinging" arms of that switch to show mechanical linkage.

You might want to look at setting up a PWM driver for each motor so that the motor speed can be reduced. Your current setup applies full battery power to the motor, putting a lot of stress on all your mechanical components at startup.